Product and process for its manufacture

A product and raw material technology, applied in the field of products and their preparation, can solve problems such as poor shelf life and changes in sensory properties of yogurt products, and achieve the effect of improving structure/texture properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

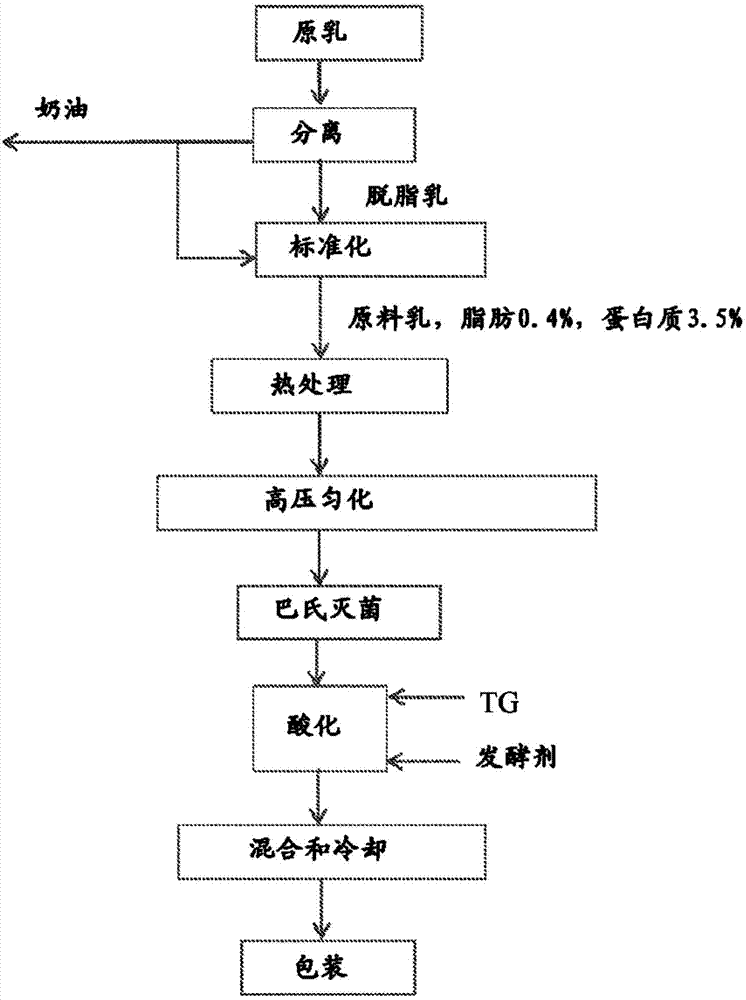

[0054] According to one embodiment of the invention, the method of preparing a yogurt product comprises:

[0055] - physical modification of milk raw materials,

[0056] - treated with a cross-linking enzyme, and

[0057] - acidification, and

[0058] - Optionally, packaging the product.

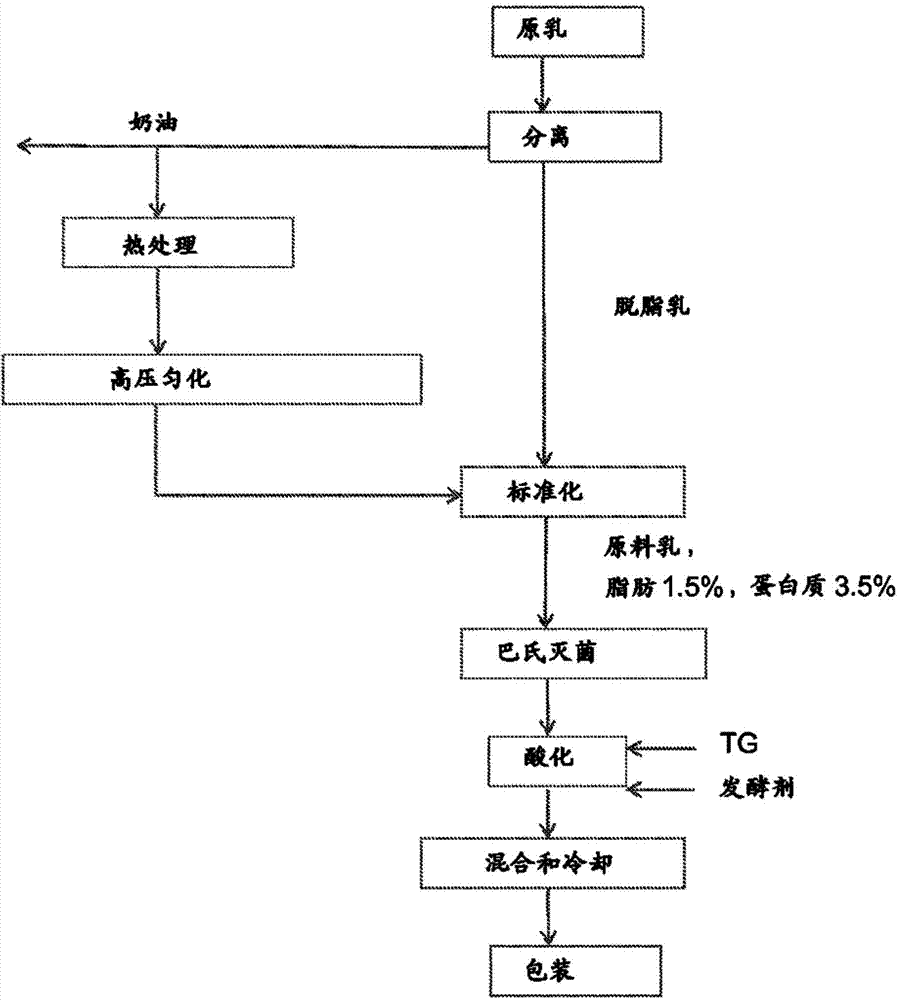

[0059] According to a second embodiment of the present invention, the method for preparing a yogurt product comprises:

[0060] - physical modification of the fat fraction of the milk raw material by combining it with non-homogenised skim milk or skim milk conventionally homogenized at low pressure,

[0061] - treated with a cross-linking enzyme, and

[0062] - acidification, and

[0063] - Optionally, packaging the product.

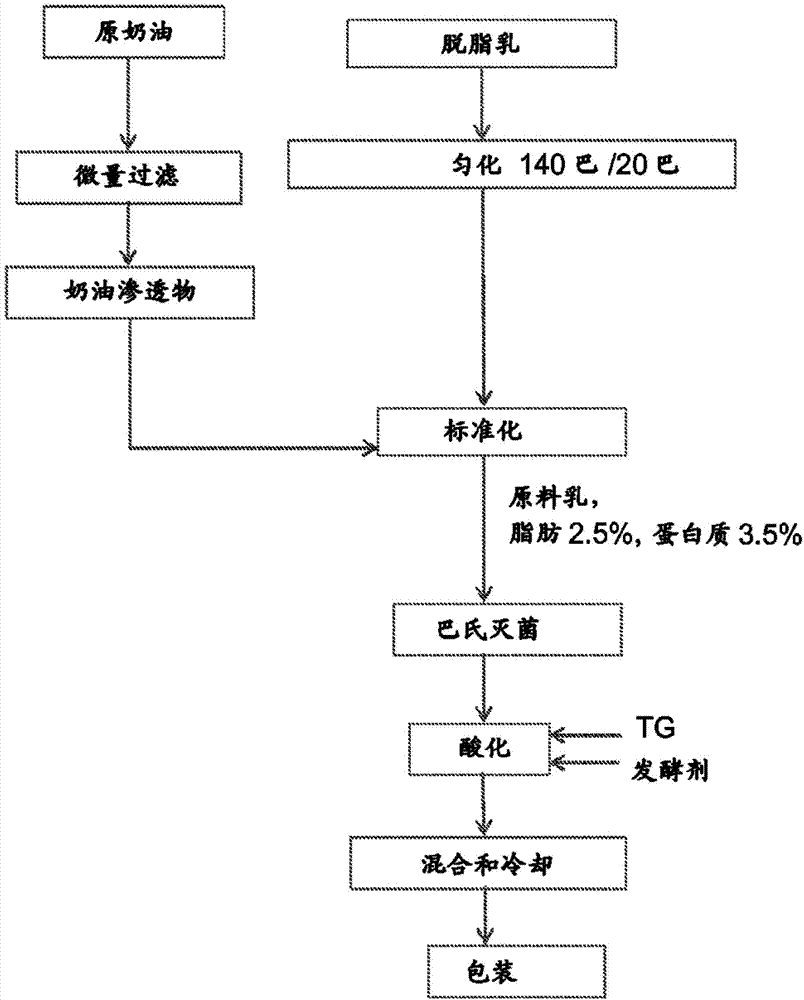

[0064] According to another embodiment of the present invention, a method of preparing a yogurt product comprises:

[0065] - combining natural and / or physically modified fat globules with non-homogenised skim milk or conventionally homogenized skim milk at low ...

Embodiment 1

[0148] Yogurt prepared from raw milk (400 bar and TG treatment)

[0149] The test yoghurts according to the invention were prepared from raw milk (4.1% fat and 3.4% protein) subjected to high-pressure homogenization at a temperature of 60° C. and a pressure of 400 bar. Thereafter, the milk is pasteurized and cooled to a temperature of 42°C. Add TGase 0.6U / g (protein) and starter. The mixture was acidified to its pH of 4.5. The mixture was mixed, cooled to 20°C, and packaged. Thereafter, the mixture was transferred to a cryogenic chamber and cooled to a temperature of 5°C.

[0150] A control yoghurt was prepared in the same manner, except that no TG enzyme was added when the starter was added.

[0151] The viscosity of the inventive yoghurt was 30% thicker at one week and 65% thicker at three weeks than the control yoghurt.

Embodiment 2

[0153] Yogurt prepared from milk containing 1.0% fat (400 bar and TG treatment)

[0154] The yoghurts tested according to the invention were prepared from milk (1.0% fat and 3.5% protein) subjected to high-pressure homogenization at a temperature of 60° C. and a pressure of 400 bar. Thereafter, the milk is pasteurized and cooled to a temperature of 42°C. Add TGase 0.6U / g (protein) and starter. The mixture was acidified to its pH of 4.5. The mixture was mixed, cooled to 20°C, and packaged. Thereafter, the mixture was transferred to a cryogenic chamber and cooled to a temperature of 5°C.

[0155] A control yoghurt was prepared in the same manner, except that no TG enzyme was added when the starter was added.

[0156] The viscosity of the inventive yoghurt was 100% thicker than the control yoghurt throughout the 3 week storage period.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com