A method of processing nectar-scented black tea by using Lingyun Pekoe tea

A technology of Lingyun Pekoe tea and nectar, which is applied in the field of tea processing, to achieve the effects of making up for the difficulty of preservation, making the soup red and bright, and improving the utilization of tea tree resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

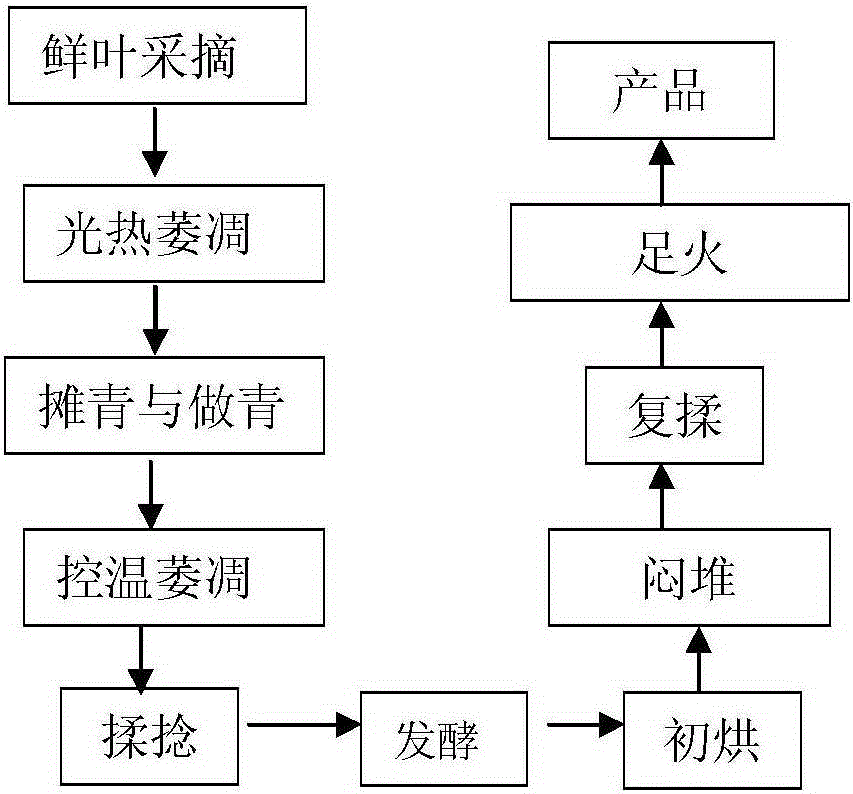

Method used

Image

Examples

Embodiment 1

[0030] Pick 5kg of fresh leaves of Lingyun Pekoe tea with 1-3 leaves of a bud. Thinly spread the raw materials of fresh leaves on a bamboo sieve and move them outdoors for photothermal withering. The surface temperature of photothermal withering is 25°C, and the time is 25min. The water loss rate of fresh leaves is 7%, and the tea after photothermal withering is obtained. Carry out spreading blue and green processing to it successively again. Spreading green is to spread 60min under the condition of room temperature of 20 DEG C in the blue green booth; described making green is to shake green and cool green and repeat alternately 2 times, each time of shaking green and green is 10min, each time of drying green and green for 1h, and the speed of shaking green and green is 30 revolutions / min. The tea leaves after greening are spread out, and the temperature is controlled and withered for 15 hours at a temperature of 25° C. and a relative humidity of 60%, to obtain the temperatu...

Embodiment 2

[0034] Pick 5kg of fresh leaves of Lingyun Pekoe tea with 1-4 leaves in a bud. Thinly spread the raw materials of fresh leaves on a bamboo sieve and move them outdoors for photothermal withering. The surface temperature of photothermal withering is 28°C for 30 minutes, and the water loss rate of fresh leaves is 8%. The tea leaves after photothermal withering are obtained. Carry out spreading blue and green processing to it successively again. Green spreading is to spread green green at room temperature at 18°C for 80 minutes in the blue green booth; the green green is shaken and cool green repeated alternately once, and the time for shaking green green is 5 minutes each time, and the time for drying green green is 1.5 hours each time. 50 rpm. The tea leaves after greening are spread out, and the temperature is controlled and withered for 14 hours at a temperature of 26° C. and a relative humidity of 70%, so as to obtain the temperature controlled and withered tea leaves. T...

Embodiment 3

[0039] Pick 5kg of fresh leaves of Lingyun Pekoe tea with 1-4 leaves in a bud. Thinly spread the raw materials of fresh leaves on a bamboo sieve and move them outdoors for photothermal withering. The surface temperature of photothermal withering is at 30°C for 25 minutes, until the water loss rate of fresh leaves is 5%, and the tea leaves after photothermal withering are obtained. Carry out spreading blue and green processing to it successively again. Green spreading is to stand green green at room temperature at 20°C for 70 minutes; the green green is shaken green and cool green alternately for 3 times, each time for shaking green green is 4 minutes, and each time for drying green green is 2.0h. 40 rpm. After greening, the tea leaves are spread out and withered under temperature control for 18 hours at a temperature of 20°C and a relative humidity of 55%. The temperature-controlled and withered tea leaves are then subjected to air kneading, medium pressure, heavy pressure, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com