Calibration device and calibration method for micro-flow thermal mass flow controller

A mass flow and calibration device technology, which is applied in the direction of testing/calibration devices, measuring devices, liquid/fluid solid measurement, etc., can solve the problems of large influence, limiting the lower limit of calibration of calibration devices, and difficulty in measuring small pressure changes. Effects that are difficult to measure precisely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described below with reference to the drawings. Elements and features described in one drawing or one embodiment of the present invention may be combined with elements and features shown in one or more other drawings or embodiments. It should be noted that representation and description of components and processes that are not related to the present invention and known to those of ordinary skill in the art are omitted from the drawings and descriptions for the purpose of clarity.

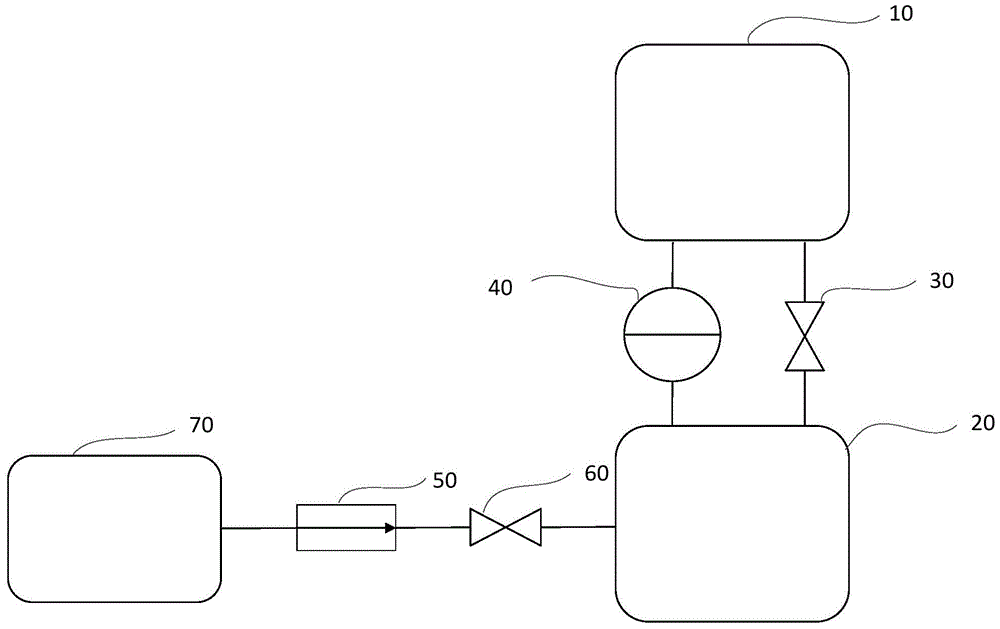

[0020] see figure 1 Shown is a structural diagram of an embodiment of the calibration device of the micro-flow thermal mass flow controller of the present invention.

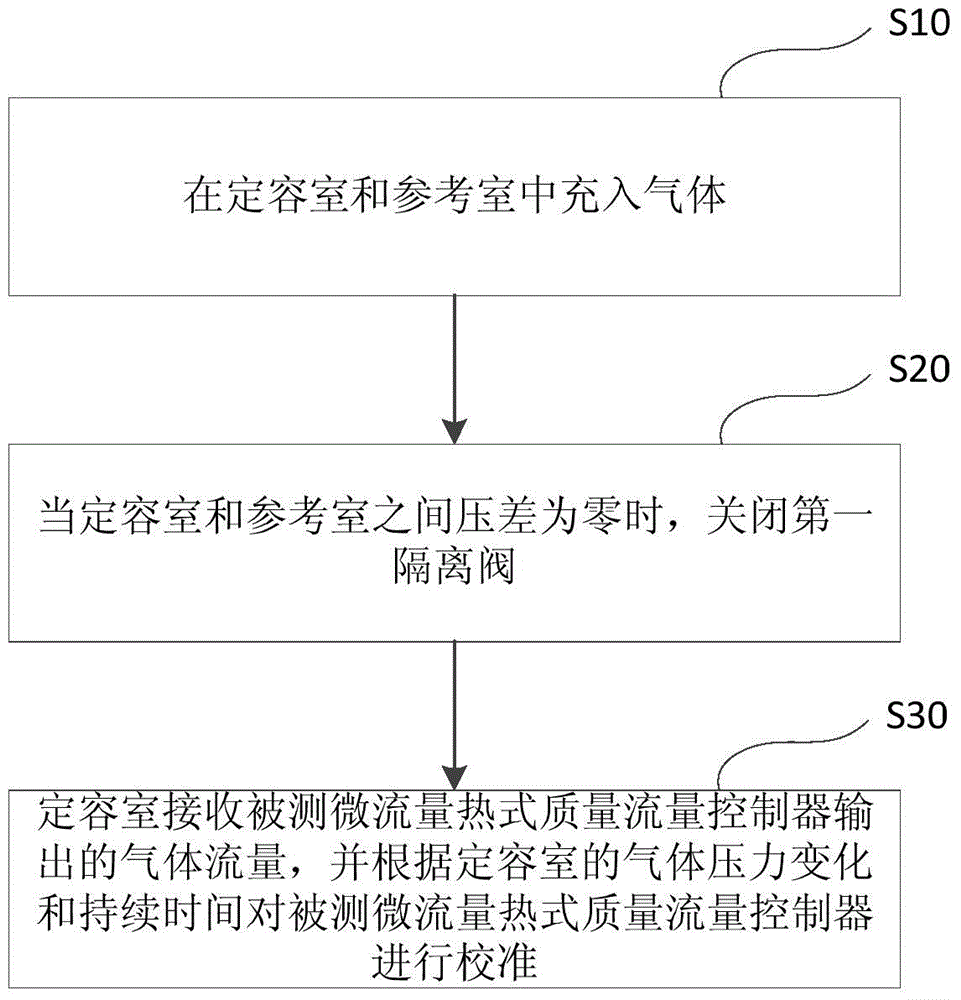

[0021] In this embodiment, the calibration device of the micro-flow thermal mass flow controller includes a reference chamber 10 and a constant volume chamber 20 , and a first isolation valve 30 and a differential pressure gauge 40 connected between the constant volume chamber and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com