Novel low-emissivity coated glass and preparation method thereof

A low-emissivity coating and glass technology, applied in the direction of chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the color fluctuation of coated products, surface nodulation discharge, affect the power and life of the target, etc. problems, to achieve stable optical and thermal properties, high visible light transmittance, and suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

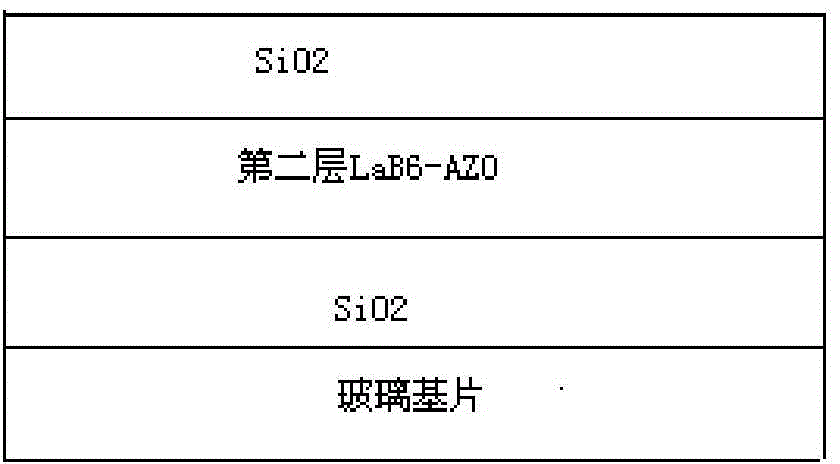

[0028] A low-emissivity coated glass, including a glass substrate and a coating layer, the coating layer includes from the inside to the outside: the first layer of SiO 2 The thickness is 40nm, the second layer of LaB 6 -AZO thickness is 473nm, third layer SiO 2 The thickness is 30nm.

[0029] The LaB 6 -AZO layer is directly sputtered into LaB by vacuum magnetron sputtering method 6 Zinc-aluminum oxide targets, of which LaB 6 The incorporation amount was 5 wt%.

Embodiment 2

[0031] A low-emissivity coated glass, including a glass substrate and a coating layer, the coating layer includes from the inside to the outside: the first layer of SiO 2 The thickness is 40nm, the second layer of LaB 6 -AZO thickness is 400nm, third layer SiO 2 The thickness is 30nm.

[0032] The LaB 6 -AZO layer is directly sputtered into LaB by vacuum magnetron sputtering method 6 Zinc-aluminum oxide targets, of which LaB 6 The blending amount is 10 wt%.

Embodiment 3

[0034] A low-emissivity coated glass, including a glass substrate and a coating layer, the coating layer sequentially includes:

[0035] The first layer of SiO 2 The thickness is 40nm, the second layer of LaB 6 -AZO thickness is 500nm, third layer SiO 2 The thickness is 30nm.

[0036] The LaB 6 -AZO layer is directly sputtered into LaB by vacuum magnetron sputtering method 6 Zinc-aluminum oxide targets, of which LaB 6 The incorporated amount is 2.5 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com