Hollow plate window opener

A window opener and hollow board technology, which is applied in the field of sheet edge sealing, can solve the problems of affecting the appearance, low efficiency, and easy entry of water vapor into the hollow board.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

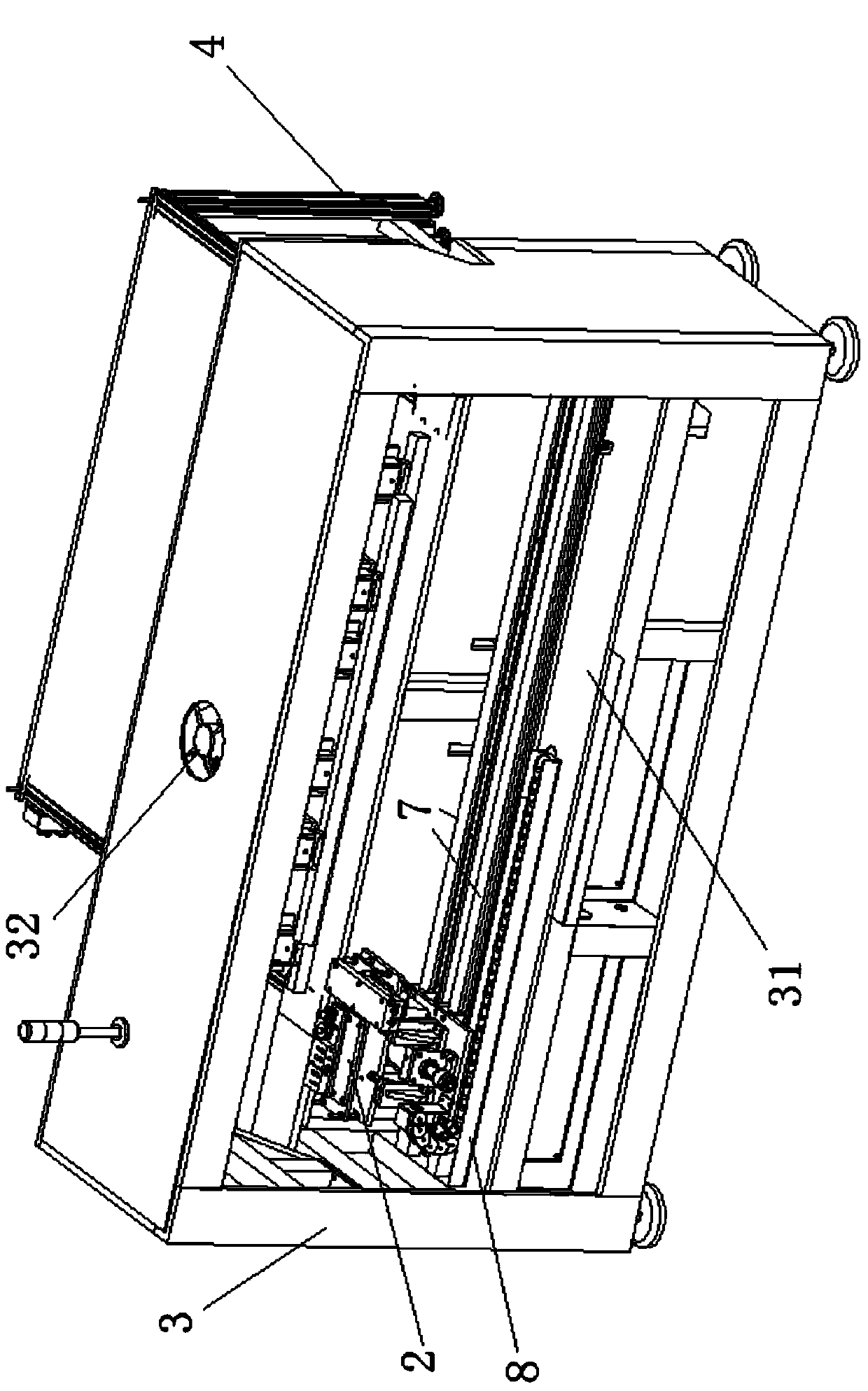

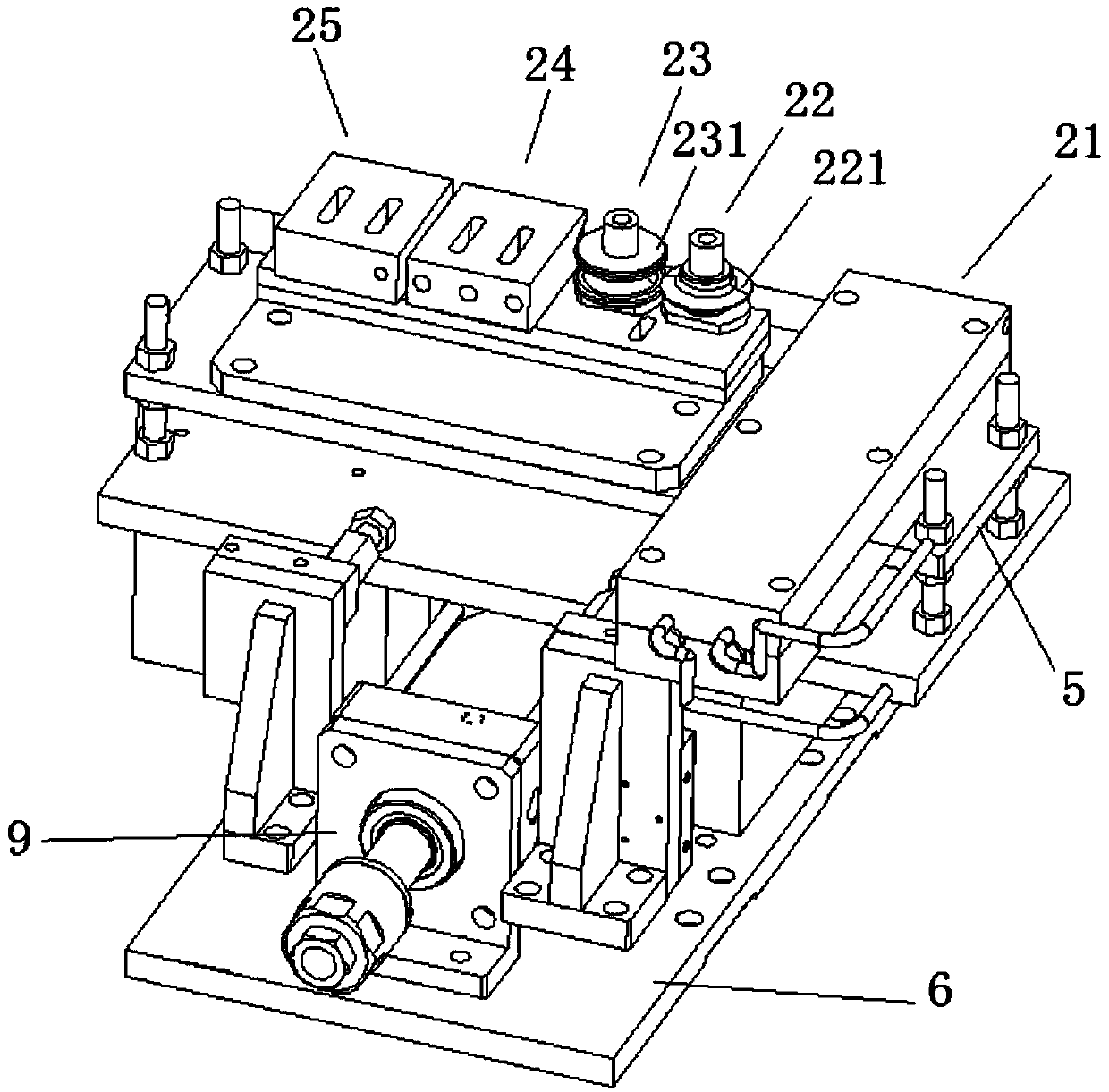

[0026] refer to Figure 2-3 It is a preferred embodiment of the present invention, which relates to a hollow panel window opening machine comprising:

[0027] A thermal die-cutting unit for at least cutting selected portions of hollow panels, and,

[0028] At least an edge banding system 2 for edge banding of the cut hollow panel side;

[0029] Among them, edge banding system 2 includes:

[0030] at least a heating unit 21 for heating the side edge of the cut hollow plate until softened,

[0031] at least a thermal cutting unit 22 for cutting the ribs in the side edges of the softened hollow panel,

[0032] A heat closing unit 23 for closing the side edge of the cut hollow plate,

[0033] A thermoforming unit 24 used to process the closed side of the hollow plate into a set sealed form,

[0034] And a cooling forming unit 25 for cooling and shaping the side edge of the hollow plate having a set shape.

[0035] Furthermore, the aforementioned cutting unit can also adopt v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com