Large-thickness blunt-trailing-edge wind turbine blade

A technology of wind turbine blades and blunt trailing edges, which is applied to wind turbines, wind turbine components, engines, etc., to achieve the effects of improving structural efficiency, reducing blade mass, and improving aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

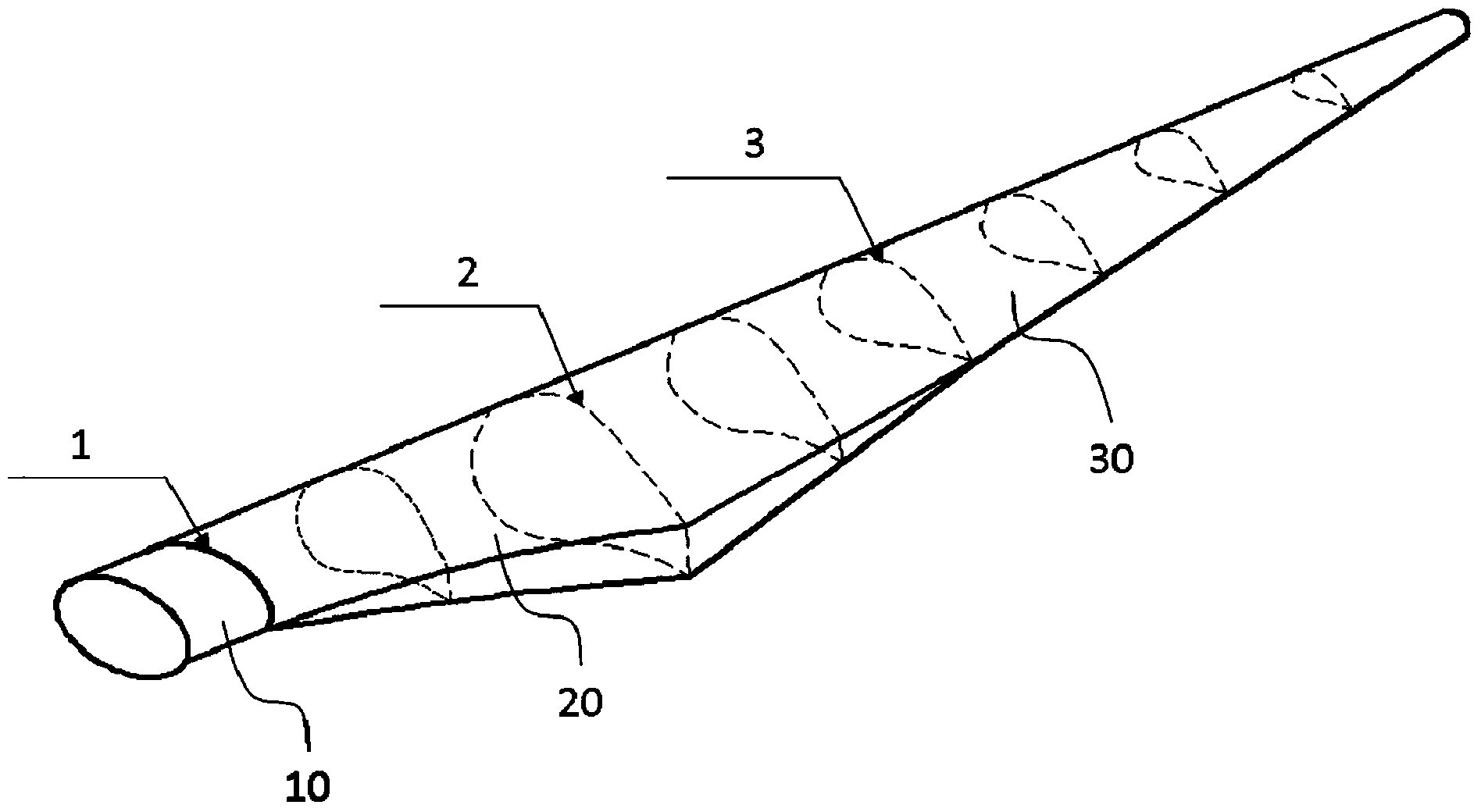

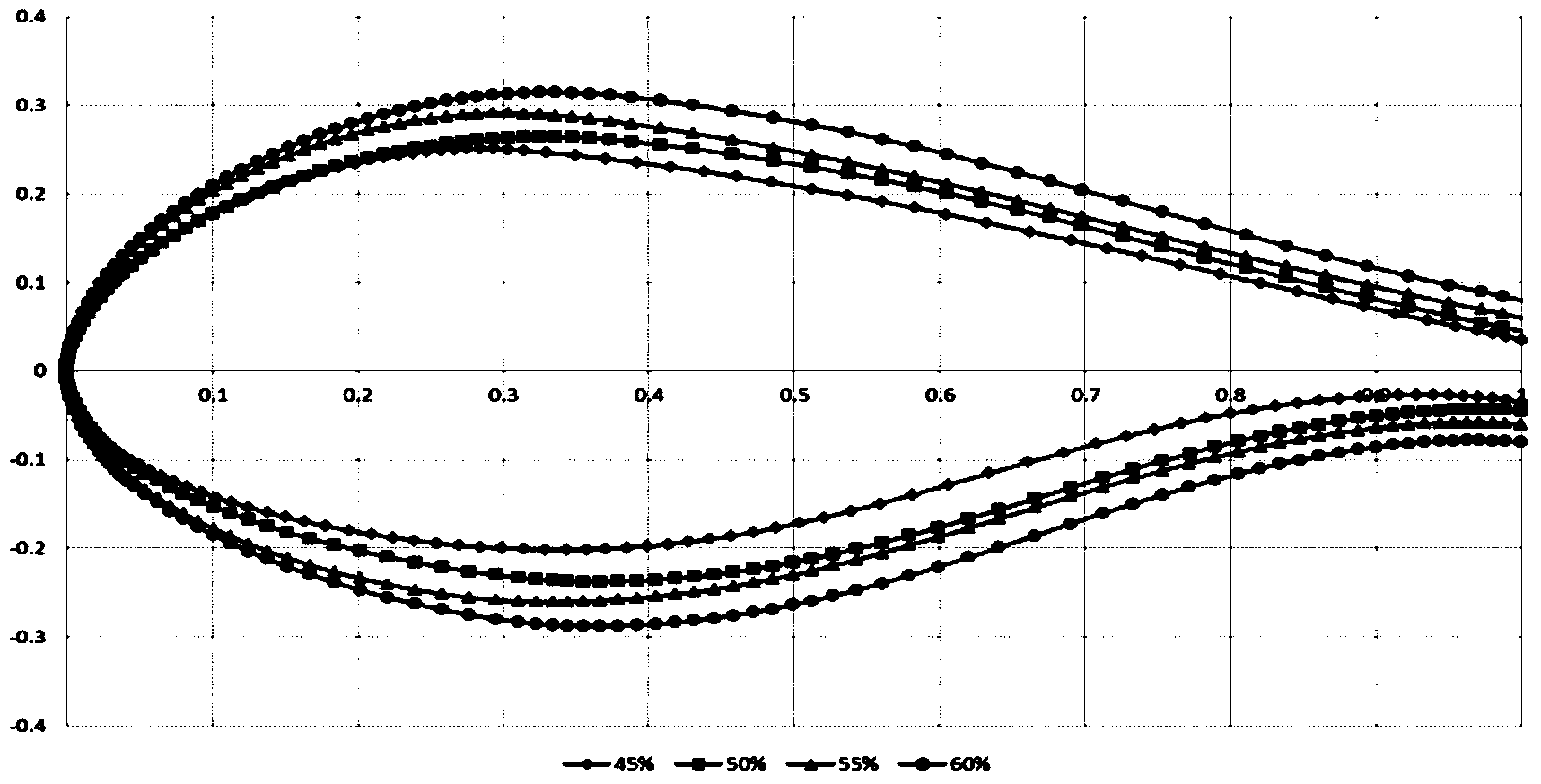

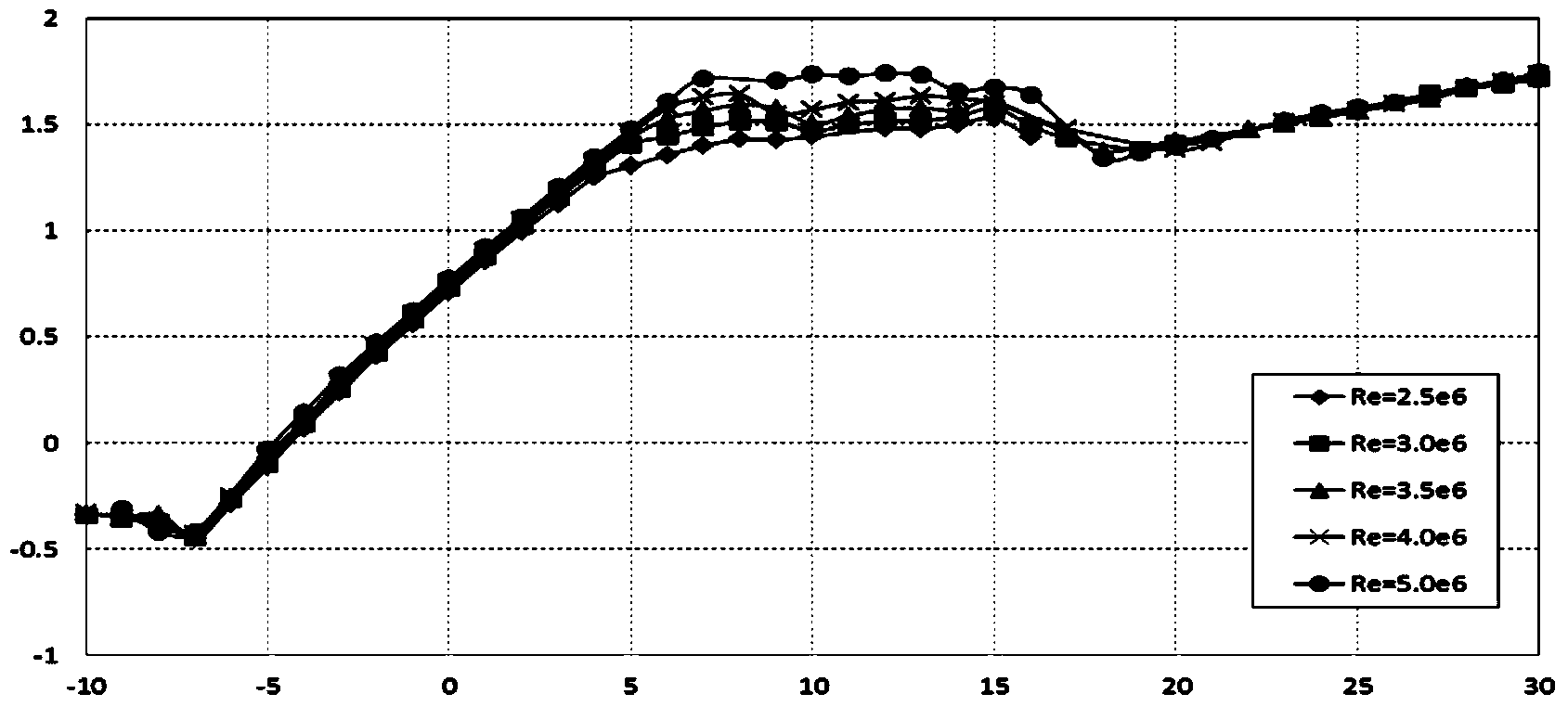

[0035] refer to figure 1, the large-thickness blunt trailing edge wind turbine blade of the present invention includes a blade cylindrical section 10, a blade transition section 20 and a blade front end 30, and the blade transition section between the circular section 1 connecting the blade root and the maximum chord length section 2 of the blade Within 20, select one or more spanwise positions to place one or more standard airfoil families with large thickness blunt trailing edges developed by the Institute of Engineering Thermophysics, Chinese Academy of Sciences, with a relative thickness of more than 40%, see Figures 2 to 6 , the relative thickness of the airfoil includes four types of large-thickness blunt trailing edge airfoils of 45%, 50%, 55% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com