Truck-mounted drilling rig rod changing device

A rod device and drill rod technology, applied in drill rods, drill pipes, drilling equipment, etc., can solve the problems of difficult handling and rod replacement, high labor intensity of workers, hidden safety hazards, etc., and achieve light weight, low working surface, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

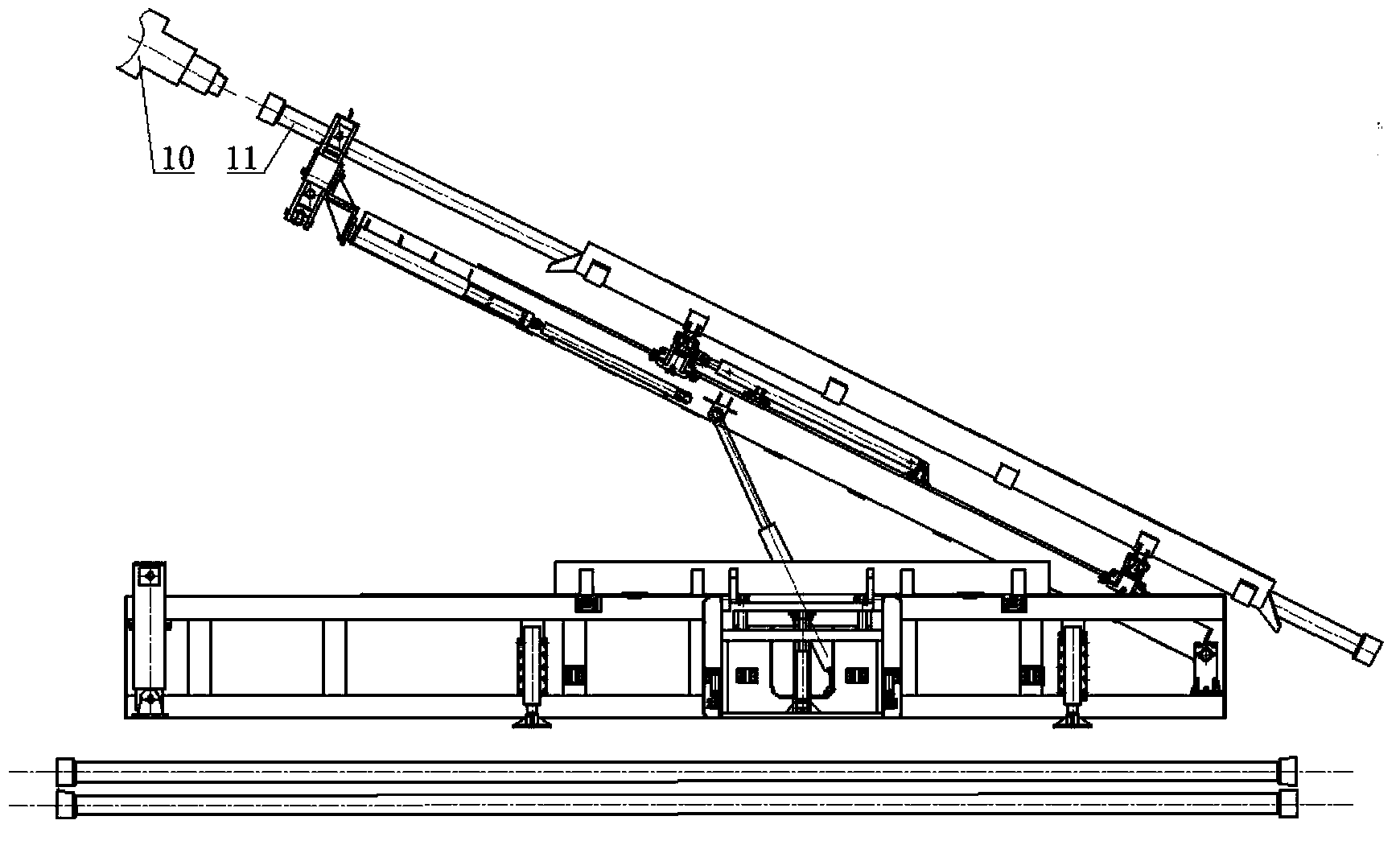

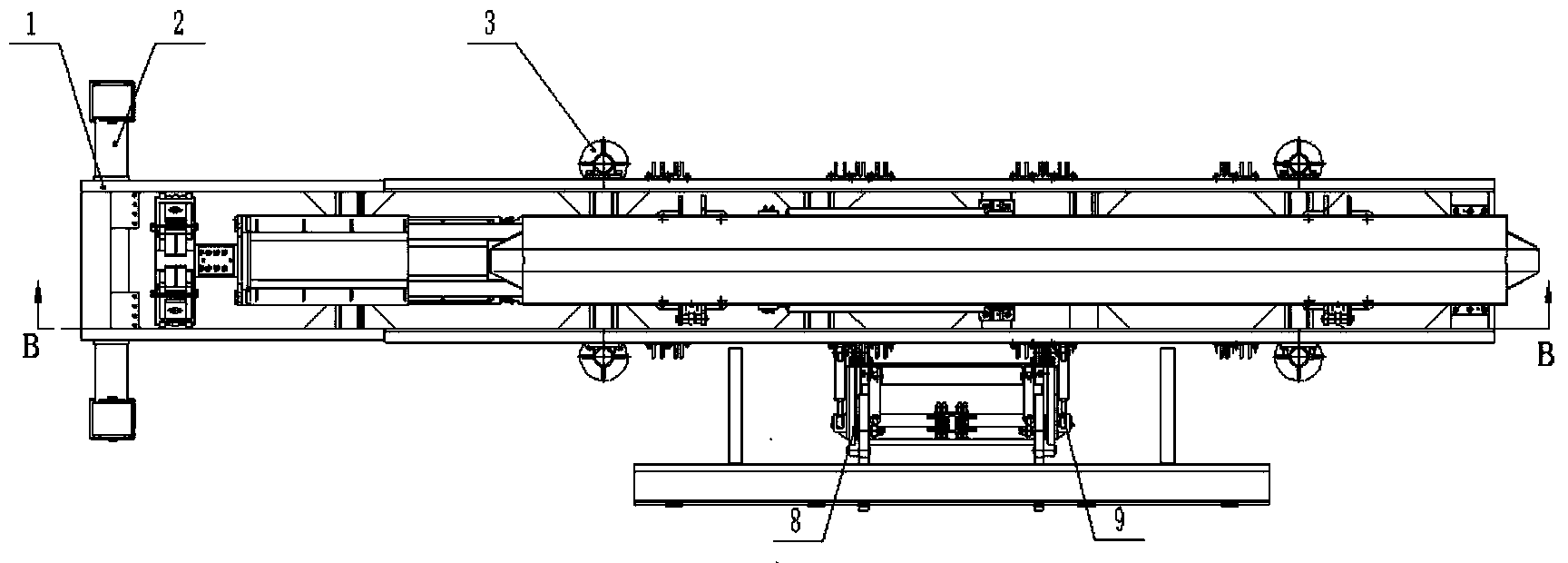

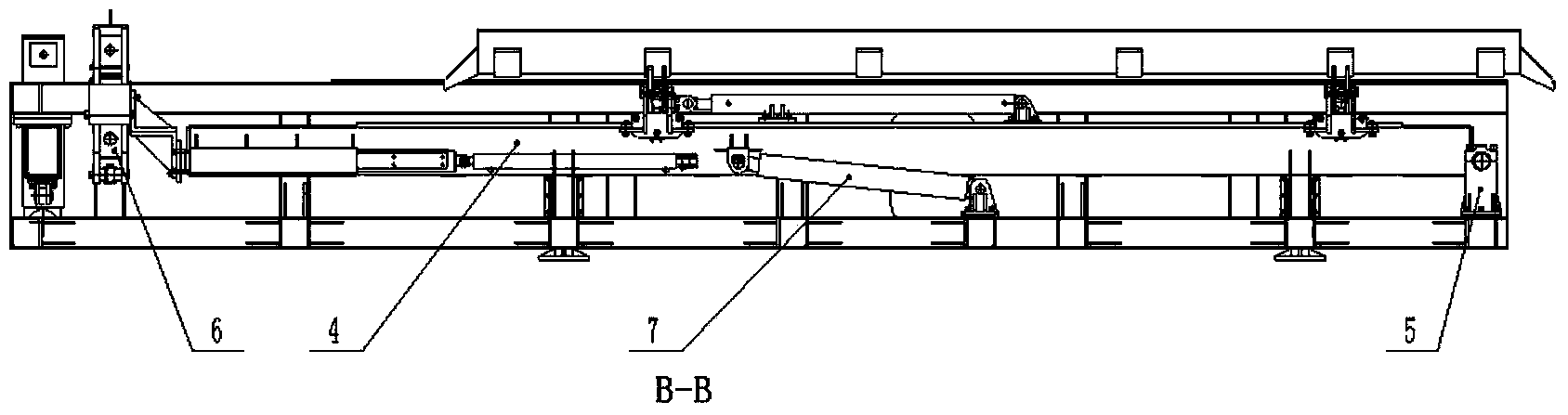

[0024] A rod changing device for a vehicle-mounted drilling rig, comprising a fuselage 1, a translation outrigger 2, a stabilizing outrigger 3, a drill pipe feeding fuselage 4, a feeding fuselage mount 5, a clamping mechanism 6, and a fuselage angle adjustment cylinder 7 , Lifting device 8, adjusting cylinder 9 and subsidiary structures. Wherein, the fuselage 1 is fixedly installed with a translation leg 2 and two pairs of stable legs 3, the drill pipe feed frame 4 is hinged with the feed frame mounting seat 5 through the feed frame rear shaft, and the clamping mechanism 6 It is fixedly installed on the drill pipe feeding body 4, and the lifting device 8 is fixedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com