Measuring probe for measuring the thickness of thin layers, and method for the production of a sensor element for the measuring probe

A technology of sensor elements and measuring probes, applied in measuring devices, electromagnetic measuring devices, electric/magnetic thickness measurement, etc., can solve the problems of reduced measurement sensitivity, excessive space, and reduced measurement accuracy, so as to improve wear resistance, Effects of high resolution and improved measurement sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

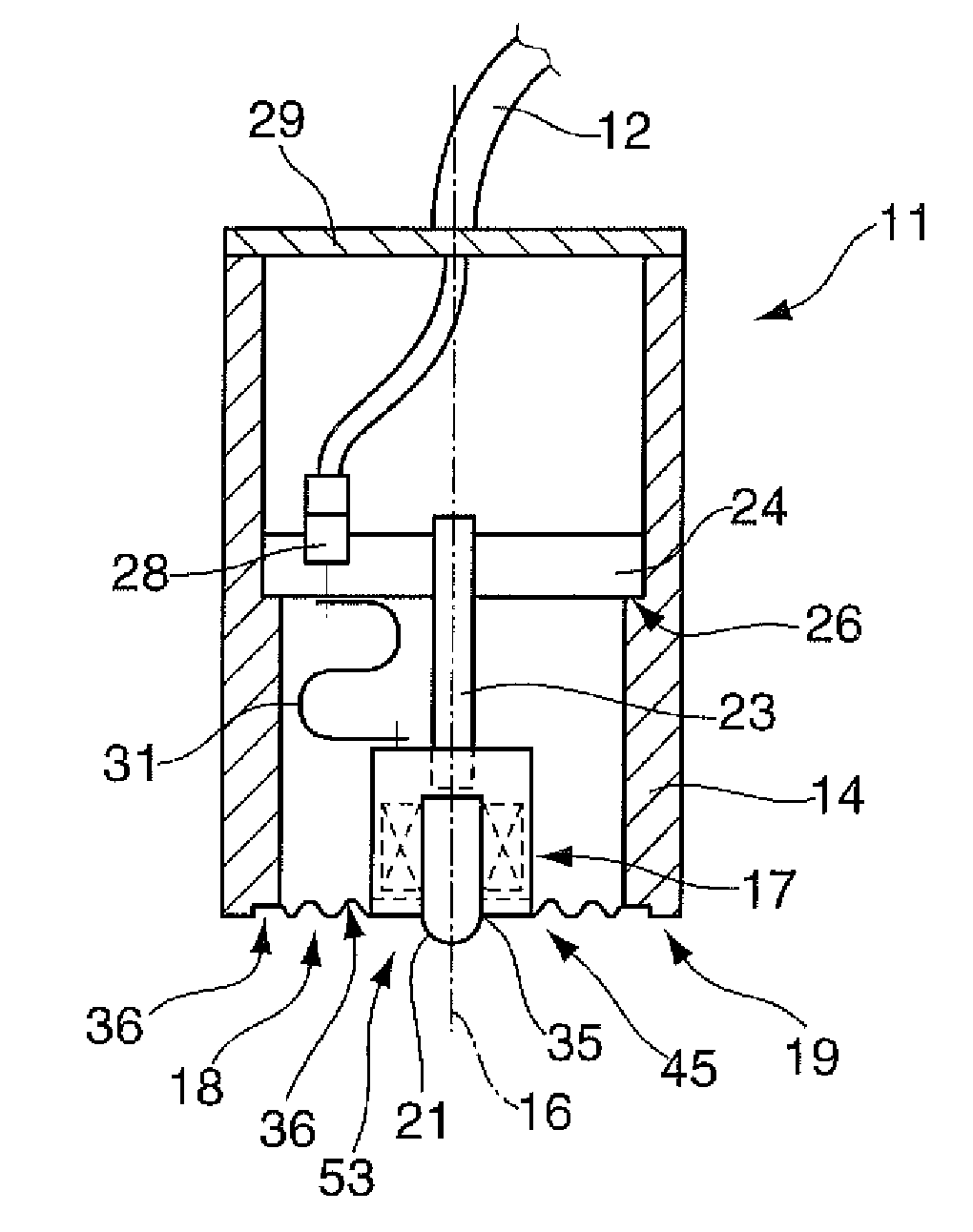

[0043] figure 1 A cross-sectional view of a measuring probe 11 for a device, not shown in more detail, for measuring the thickness of thin layers is schematically depicted in . The measuring probe 11 is used for the non-destructive measurement of the layer thickness. According to an exemplary embodiment, this measuring probe 11 may be provided separately from the data processing means of the device for measuring the thickness of the thin layer and the recorded value may be transmitted via the connecting cable 12 or wirelessly. Alternatively, the measuring probe 11 may be part of a device for measuring the thickness of thin layers in the form of a stationary device or a hand-held device.

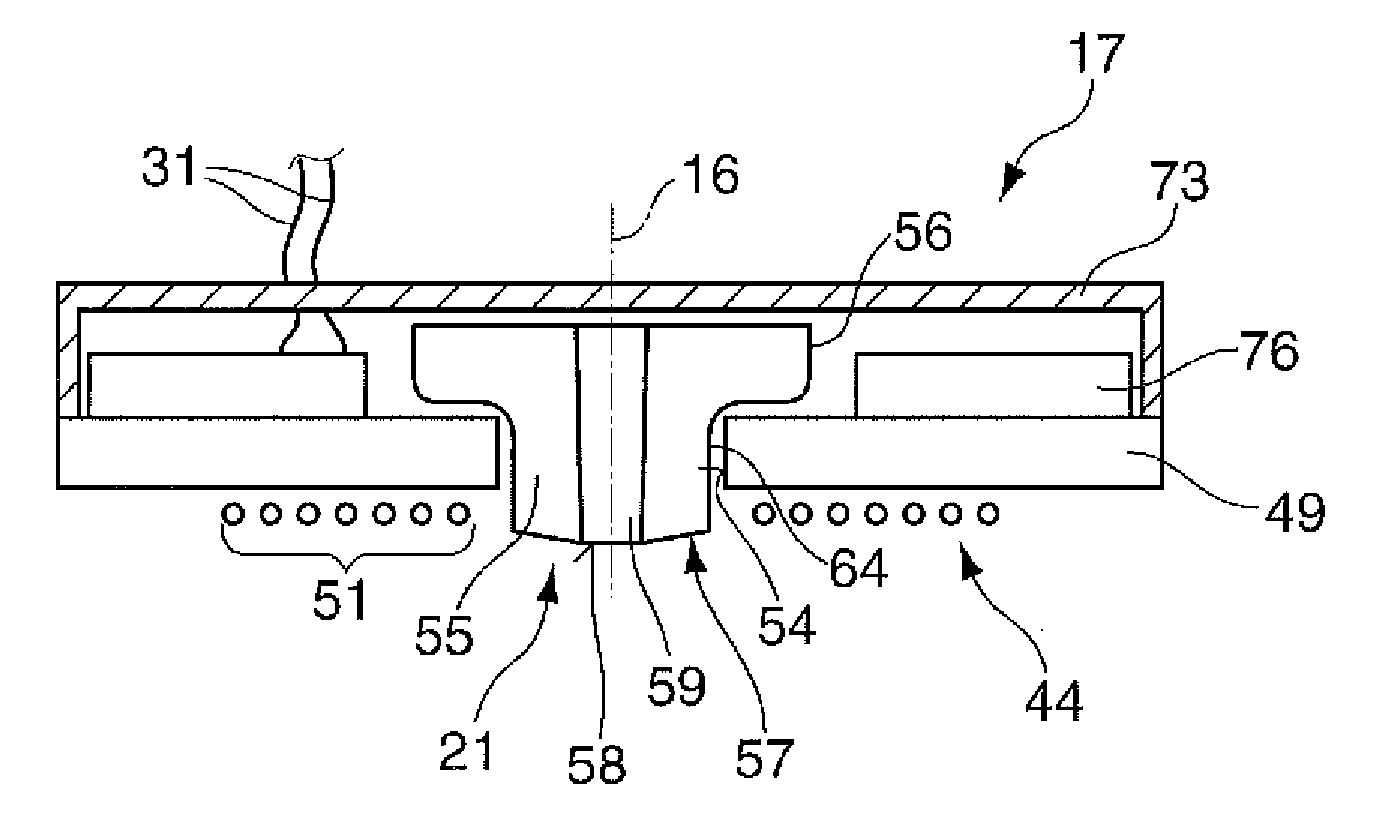

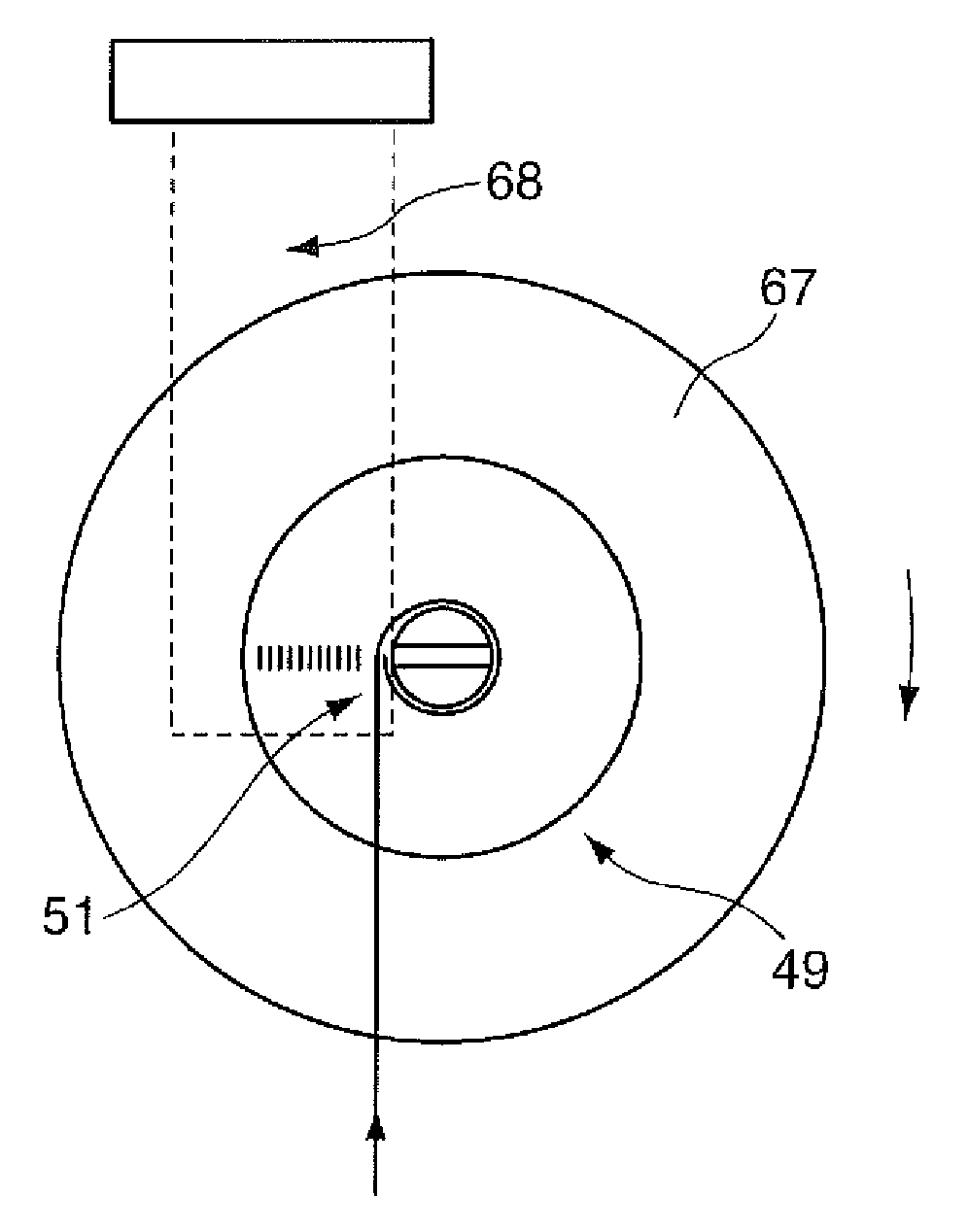

[0044] The measuring probe 11 has a housing 14 which is in particular cylindrically formed. At least one sensor element 17 is preferably arranged along the longitudinal axis 16 of the housing 14 . The sensor element 17 is carried by a holding element 18 which is accommodated on an end sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com