Dynamic Gibbs reactor modeling method

A modeling method and reactor technology, applied in instrumentation, special data processing applications, electrical digital data processing, etc., can solve problems such as the insufficiency of steady-state models to solve production problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

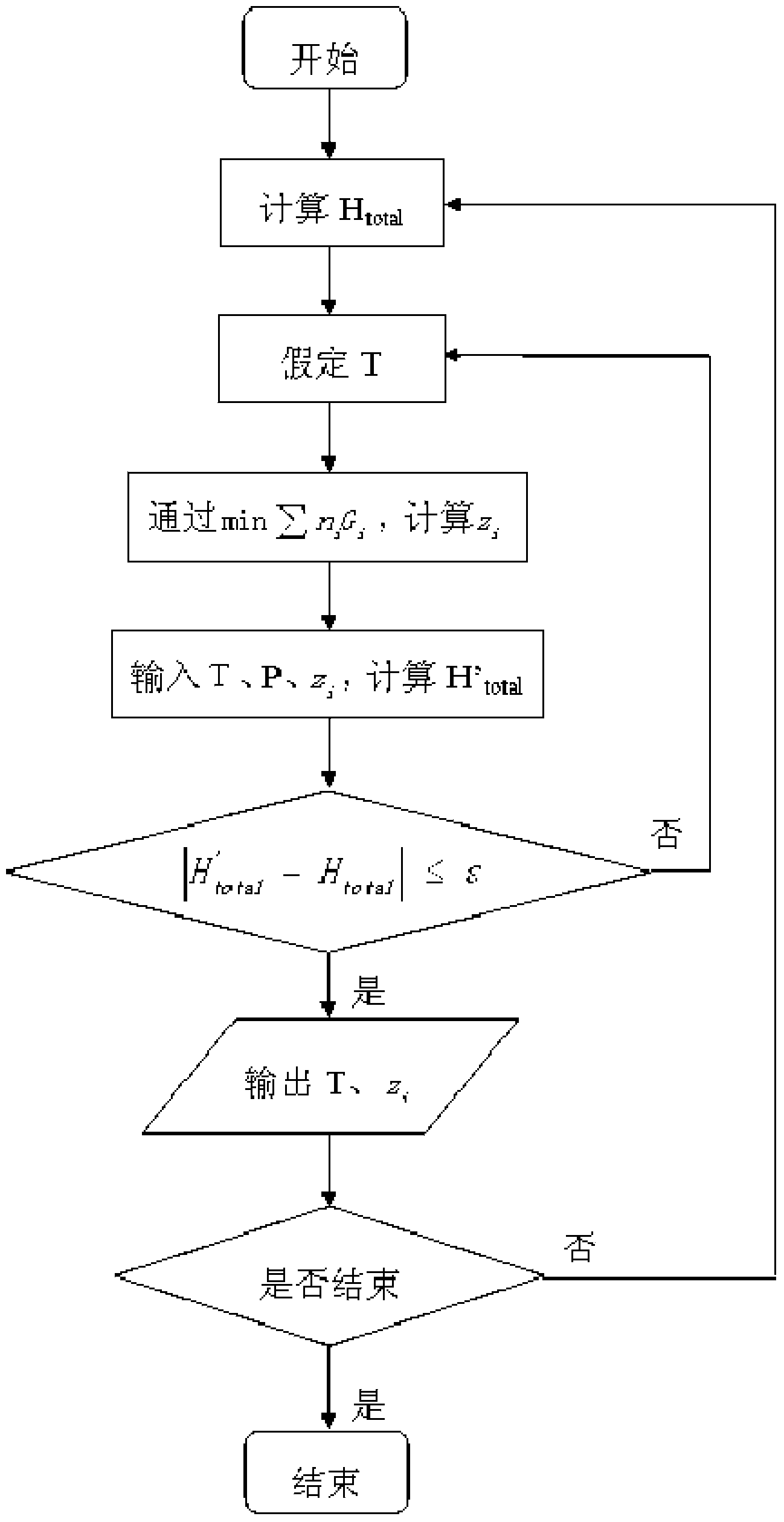

[0042] The following combination figure 1 The present invention is further described.

[0043] The mathematical models involved in the dynamic reactor modeling process include the minimum principle of Gibbs free energy of the fluid, the material balance equation and the energy balance equation, etc. For specific steps, see figure 1 .

[0044] In step (1), the material balance equation in the dynamic modeling process from an initial moment t to the next moment t+Δt is established. The amount of each component in the reactor at time t, the feed composition and the flow rate are known, so in the Gibbs reactor, the material in the reactor at time t is mixed with the feed material in the time period Δt, depending on The initial reactants computed for this round. The material balance equation is established, and its model expression is:

[0045] m t+Δt = M t +Δt×∑F in

[0046] In the formula, M t+△t Calculate the amount of initial reactant for the current round, mol; M t i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com