Device and method for conditioning the flow surface of the headbox of a fiber web machine

A fiber web machine and headbox technology, which is applied in the paper machine, wet end of paper machine, textile and paper making, etc., can solve the problem that the small grinding wheel cannot meet the smoothness and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

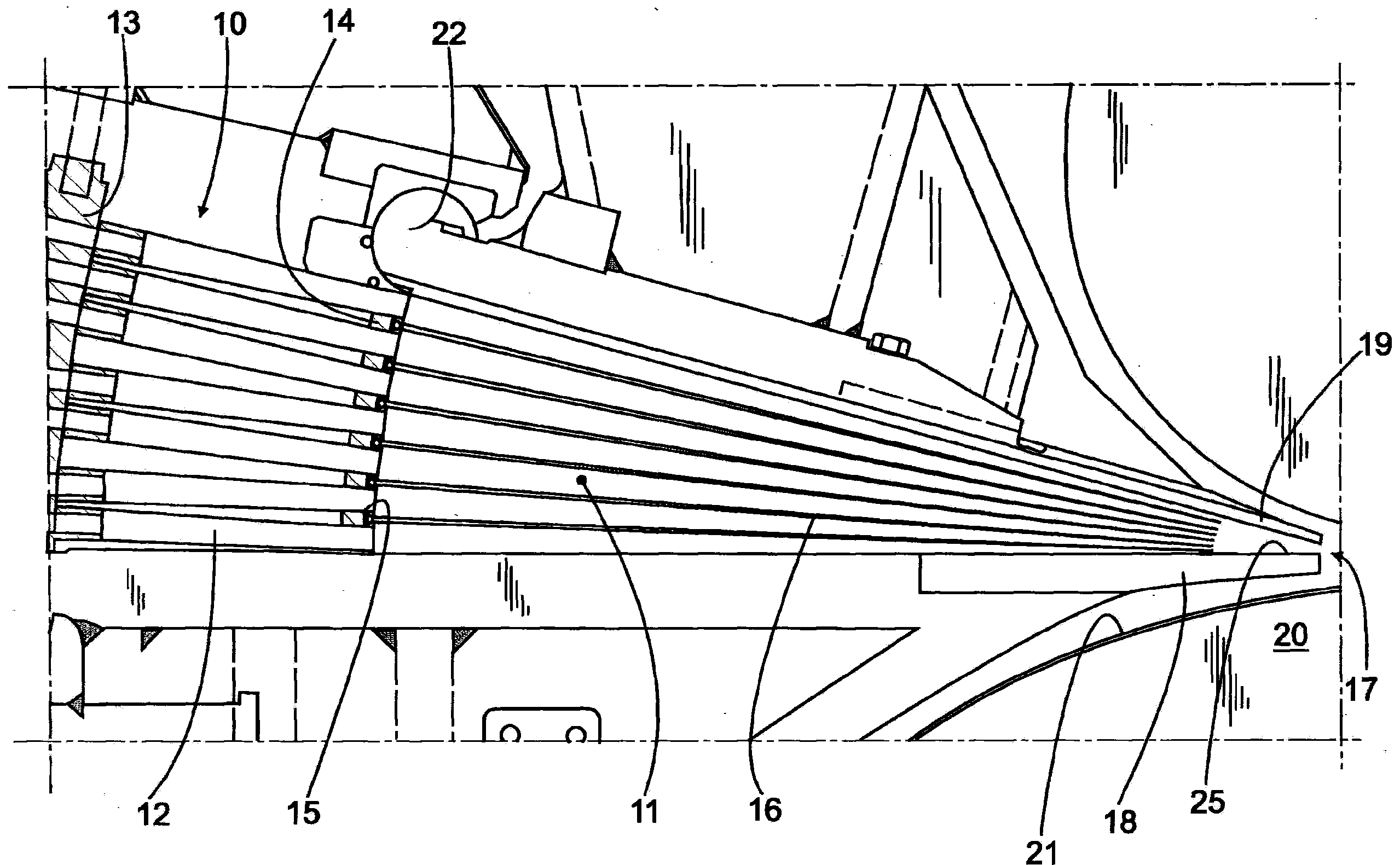

[0024] figure 1 A part of a conventional headbox of a fiber web machine is shown. Fiber web machines include, for example, paper, board and pulp machines. The fiber suspension used in the production process is fed into the slice channel 11 via a turbulence generator 10 as is known. The purpose of the turbulence generator is to separate the fibers from each other and to guide these fibers in as uncertain a manner as possible relative to each other. Here, the turbulence generator 10 consists of a plurality of tubes 12 which are supported at both ends to solid plates 13 and 14 . Holes 15 are machined in the plate delimiting the slice channel 11 and the tubes 12 have been placed in the holes 15 . exist figure 1 , there are 7 rows of tubes 12 on top of each other, and each row extends across the entire width of the headbox. The tubes 12 are placed at an angle relative to each other so that fluid discharged from different rows of tubes is brought together in the slice opening 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com