Micro arc type multiple composite reinforcement deformation-resistance high-strength profiled bar structure

A technology of anti-deformation and profiled material, applied in the direction of building components, etc., can solve the problems of easily damaged profiled material, bulky structure, insufficient strength, etc., to achieve the effect of easy production and processing, expanding the scope of application, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

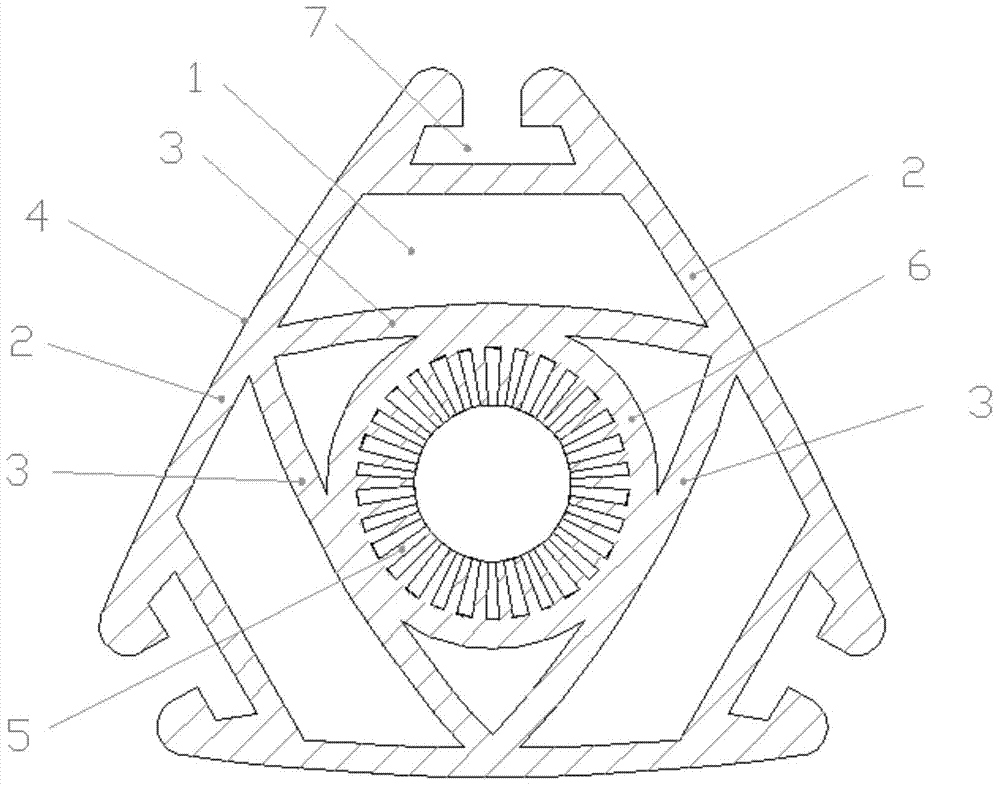

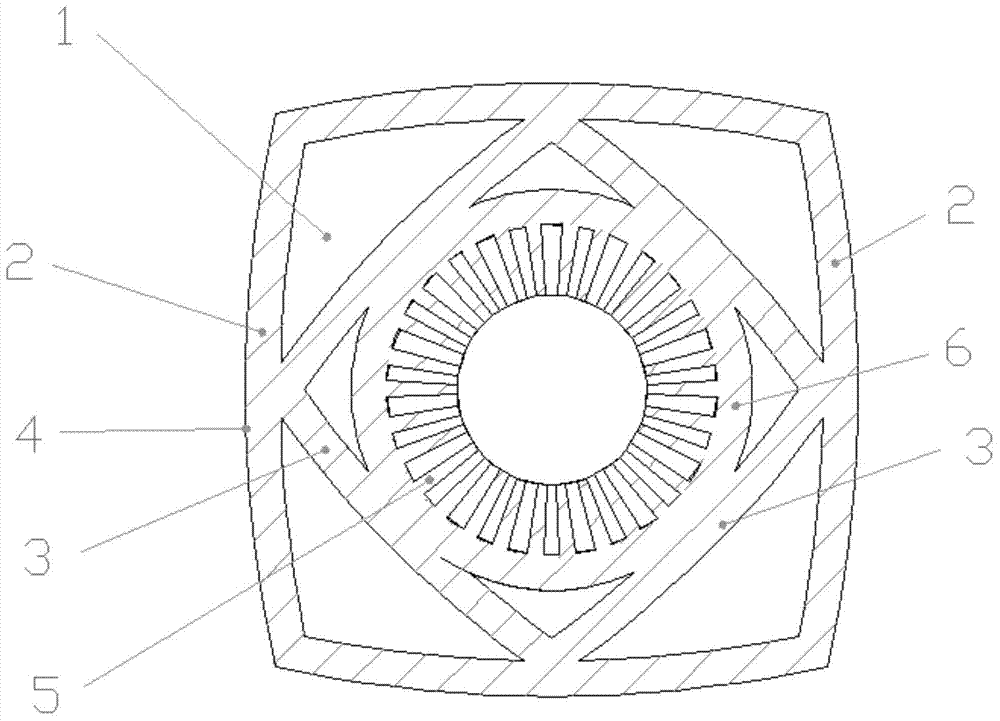

[0020] refer to figure 1 with figure 2 As shown, the micro-arc multi-composite reinforced anti-deformation high-strength profile structure includes a profile structure 1, and the profile structure 1 is connected by an outer polygonal micro-arc structure 2 and an inner polygonal micro-arc structure 3 Formed, the inner polygonal micro-arc structure 3 is connected to the centroid ring body 6, and the inner side of the centroid ring body 6 is connected with a rotating reinforcing rib 5, and the cross-sectional shapes at different positions of the rotating reinforcing rib 5 are the same, However, there is a rotation angle between the sections and sections in a threaded shape along the center line.

[0021] Further, the polygons of the outer polygonal micro-arc structure 2 and the inner polygonal micro-arc structure 3 are regular po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com