Three-dimensional physical simulation experiment method of small-sized self-weight frame-type loading

A simulation experiment and three-dimensional physics technology, which is applied in the field of mining physics simulation experiment, can solve the problems of filling similar materials, complex experiment process, and long cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

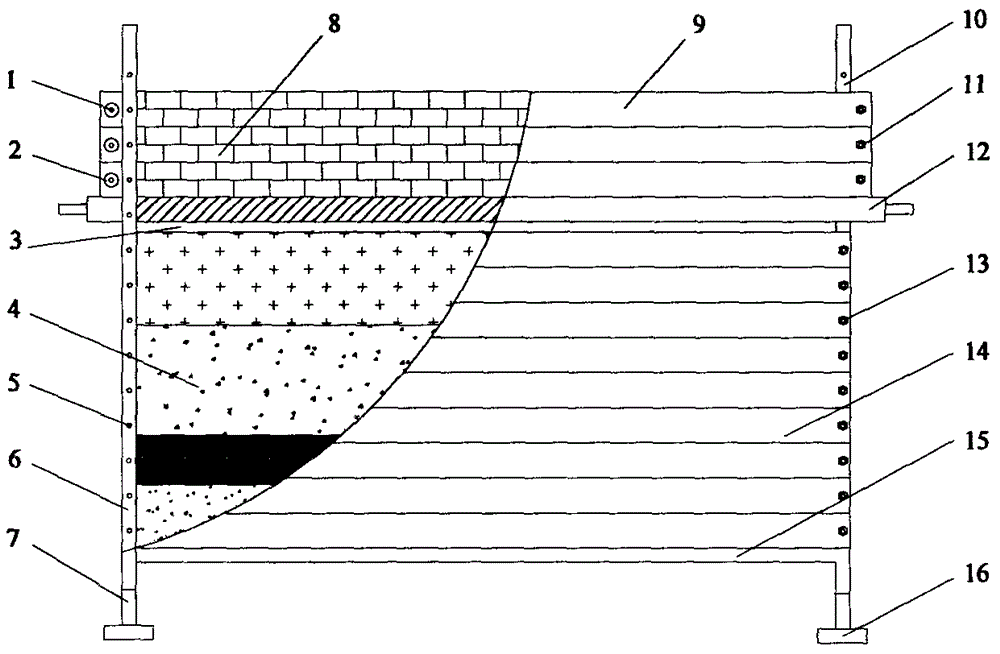

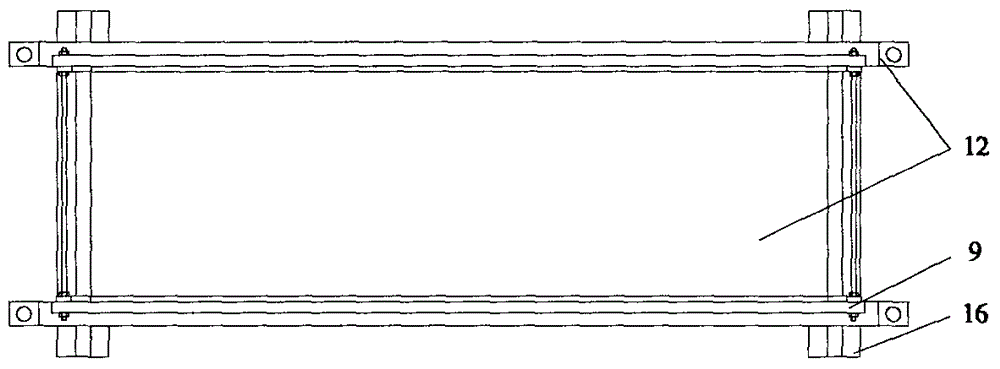

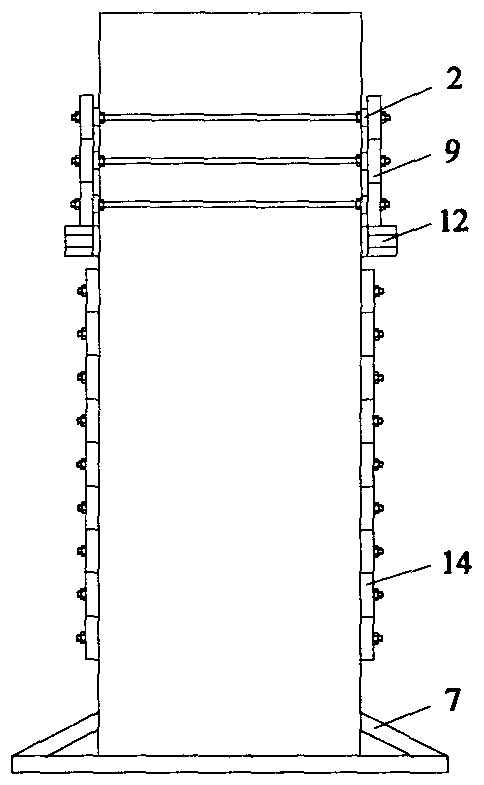

[0022] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

[0023] The invention provides a three-dimensional physical simulation experiment method for small self-weight frame-type stowage.

[0024] (1) By analyzing the simulated geological body, select appropriate similar materials and similar proportions, and determine the height of the model loading area 4 and the self-weight frame loading area 8 .

[0025] (2) Fasten the front and rear side wall panels 14 through the wall panel bolts 13 and the lower parts of the left side beam 6 and the right side beam 10 provided with the wall panel screw holes 5 to form the first similar material of the model loading area 4 Filling space, and require the installation height of the front and rear side wall panels 14 to be advisable to not affect the filling of similar materials.

[0026] (3) Fill the geological similar body in the first similar material filling space c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com