Air-driven threading device for sewing machine

一种穿线装置、缝纫机的技术,应用在上线装置、缝纫机元件、缝纫机用套圈机构等方向,能够解决弯针线穿线操作麻烦、难以理解穿线装置使用方法等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

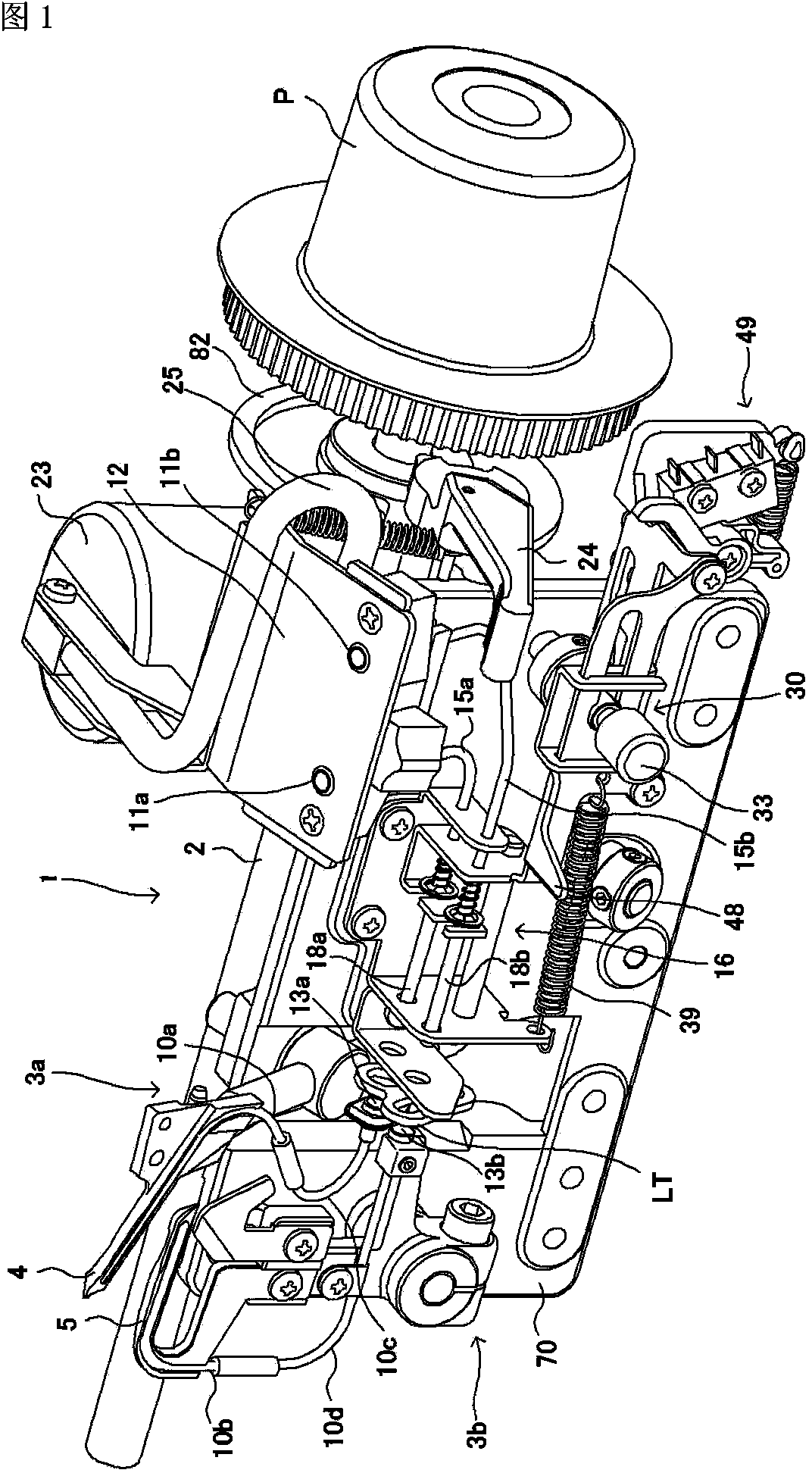

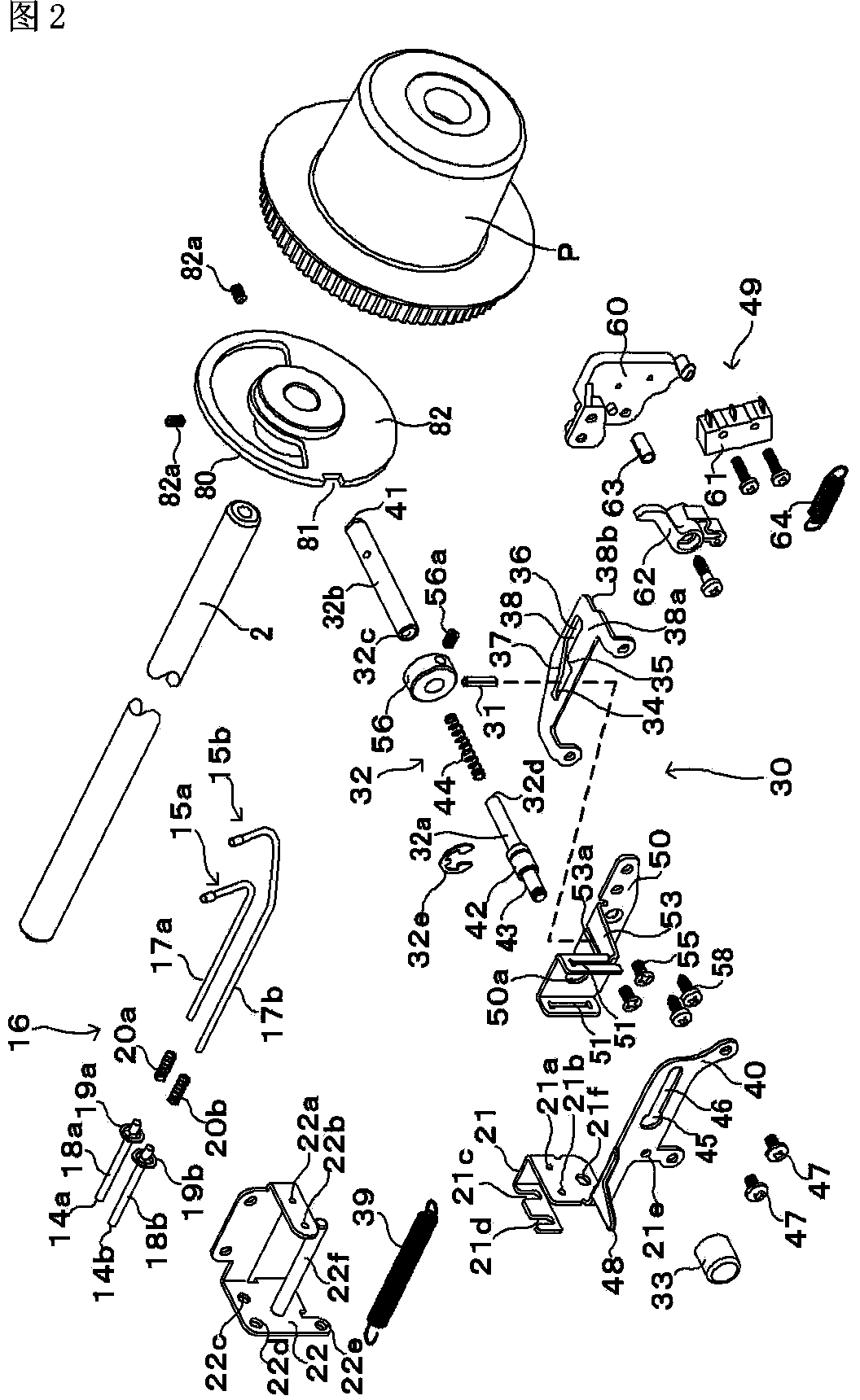

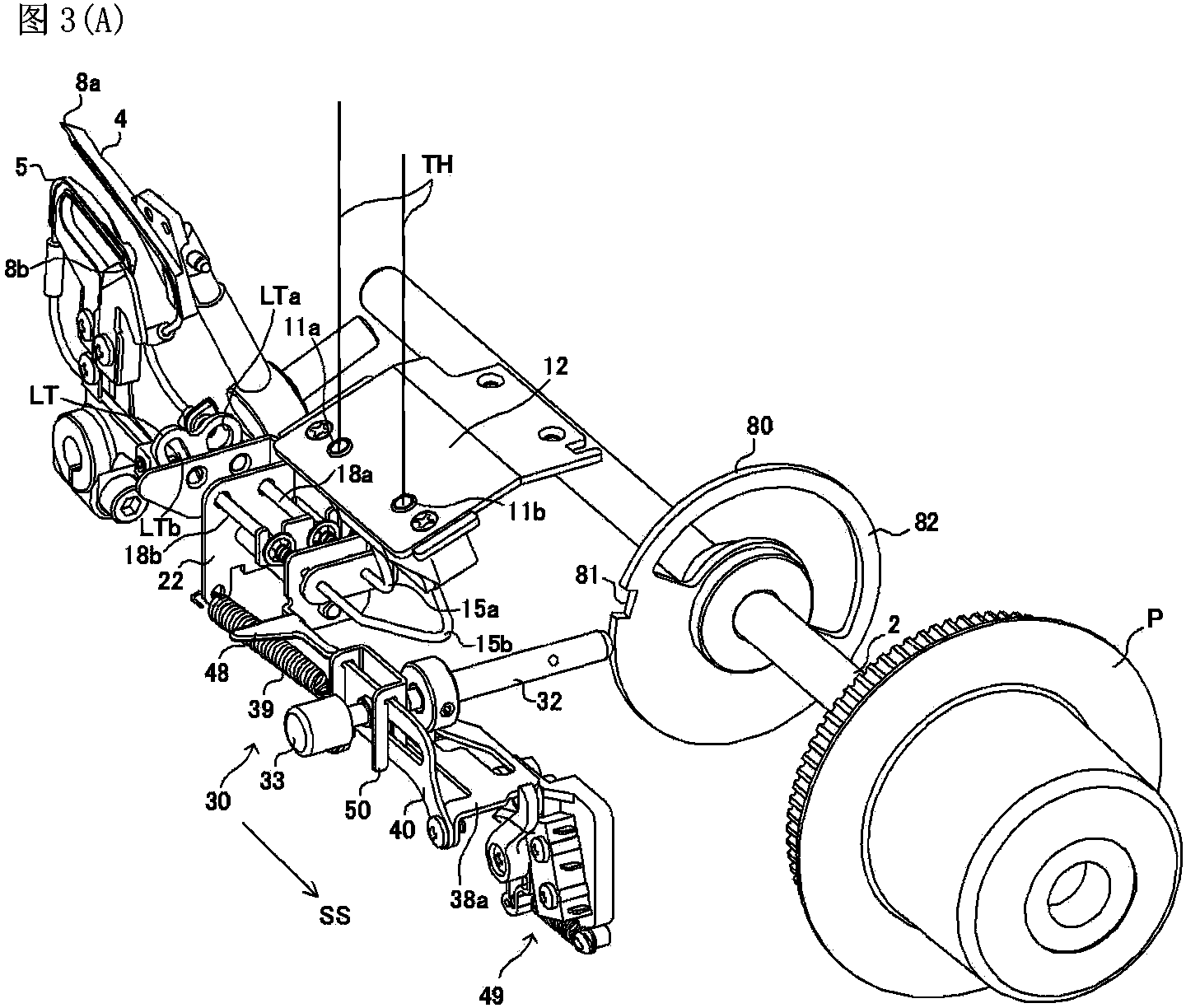

[0050] Next, a preferred embodiment of the gas conveying threading device of the present invention applied to an overlock sewing machine will be described in detail with reference to the accompanying drawings.

[0051] Such as figure 1 , Figure 9 As shown, the overlock sewing machine 1 is composed of a main frame (main frame) and a sub frame (sub frame) forming a base (bed) and an arm (arm).

[0052] The sewing machine motor M is installed on the sub-frame, and the main shaft 2 extends horizontally along the frame. The main shaft 2 is rotationally driven by a sewing machine motor M via a timing belt MB.

[0053] Synchronized with the main shaft 2, the upper looper 4 driven by the looper driving mechanism 3 (3a, 3b), the lower looper 5, the needle driven by the needle driving mechanism 6, the cloth pressing mechanism that presses the cloth on the needle plate, The cloth feeding mechanism 7 that advances the cloth one needle eye at a time constitutes a seam forming device. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com