An anti-shock interval grouting anchor cable and its application method

A technology of grouting anchor cable and anti-shock, which is applied in earthwork drilling, installation of anchor rods, mining equipment, etc., to relieve the instantaneous high stress state of the steel hinge line, improve the stress condition, and improve the overall strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

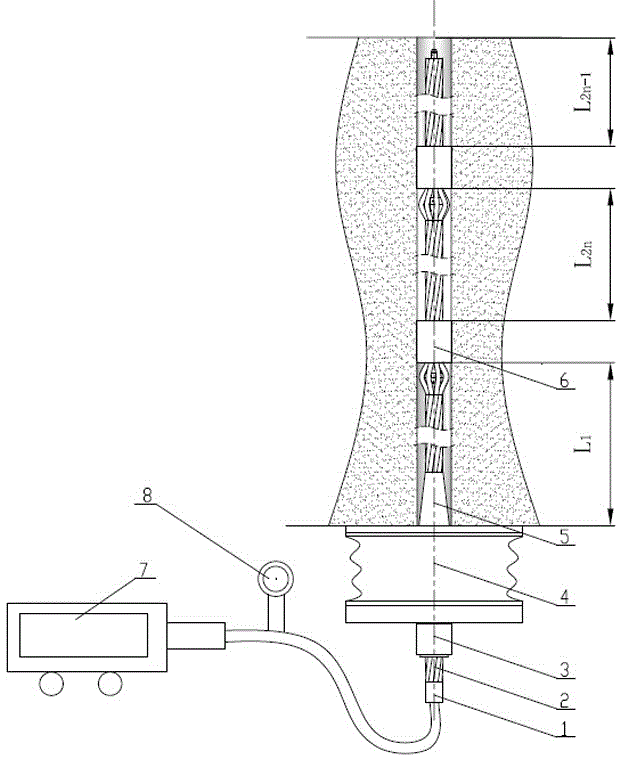

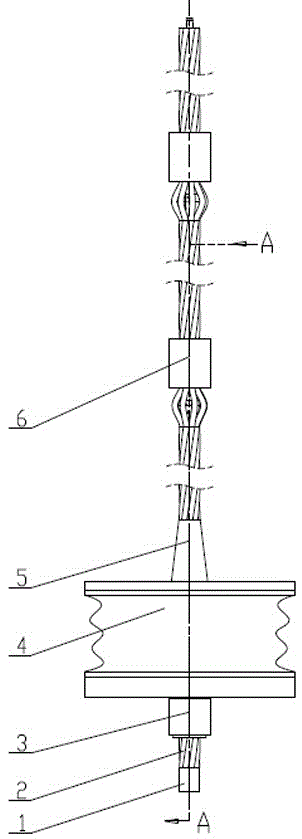

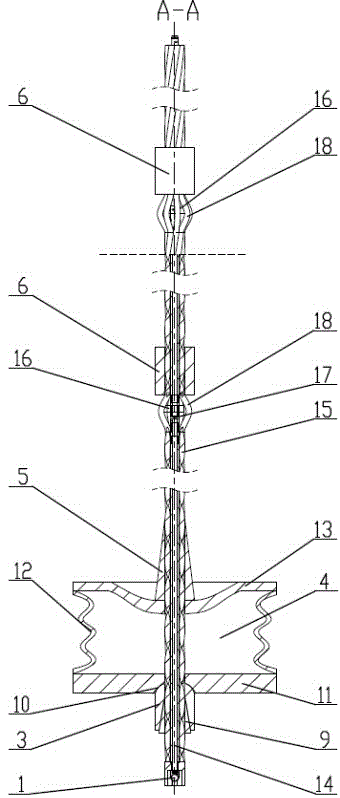

[0019] Such as Figure 1 ~ Figure 3 As shown, the present invention is an anti-impact interval grouting anchor cable and its use method, including one-way grouting valve 1, hollow grouting steel hinge line 2, arc anchor ring 3, sliding pressure shrinking ring 4, cone Stop grouting plug 5, segmented sealing plug 6, the one-way grouting valve 1 is set at the end of the hollow grouting steel hinge line for one-way high-pressure grouting, arc anchor ring 3, sliding pressure shrinking ring 4, A through hole is provided between the tapered grouting plug 5 and the segmented sealing plug 6, and the hollow grouting steel hinge line 2 passes through the through hole. The hollow grouting steel strand 2 is composed of a flexible grouting pipe 14, a hollow steel strand 15 and a steel strand expansion ring 16. The hollow steel strand 15 is provided with a steel strand expansion ring 16 every certain length to make the steel strand expand. Spread, the flexible grouting pipe 14 passes along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com