A kind of processing technology of tea

A processing technology, tea technology, applied in the field of tea processing technology, can solve problems such as failure to produce tea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

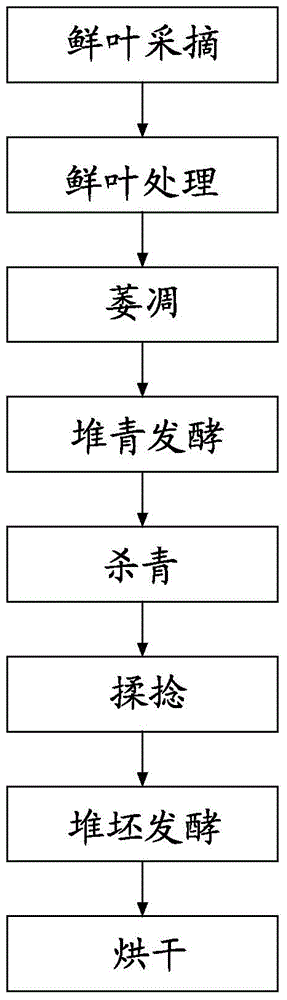

[0021] Such as figure 1 Shown, the processing technology of the tealeaves of this embodiment, comprises the steps:

[0022] A. Picking fresh leaves: Picking tea leaves by hand. The fresh leaves are the first level of one bud and one leaf. Keep the fresh leaves intact, fresh and even. ;

[0023] B. Treatment of fresh leaves: Spread the fresh leaves thinly in the green storage room to dissipate heat. The green storage room should be clean and hygienic, and the air should be ventilated; leaves) should be dehydrated immediately, and the dehydration should be carried out with a tea dehydrator or withered tank;

[0024] C. Withering: Thinly spread the fresh leaves after heat dissipation or dehydration on the bamboo sieve, and turn them once every 2 hours; withering is carried out indoors; indoor withering should be kept clean and hygienic, with air circulation; the degree of withering should be controlled from green leaves to yellow and green leaves , after the green fragrance is...

Embodiment 2

[0032] Such as figure 1 Shown, the processing technology of the tealeaves of this embodiment, comprises the steps:

[0033] A. Picking fresh leaves: Picking tea leaves by hand. The fresh leaves are the second level of one bud and two leaves. Keep the fresh leaves intact, fresh and even. ;

[0034] B. Treatment of fresh leaves: spread the fresh leaves thinly in the green storage room to dissipate heat. The green storage room should be clean and the air should be ventilated; if it encounters rain or dew green, it should be dehydrated immediately, and the dehydration should be carried out with a tea dehydrator or a withering tank. ;

[0035] C. Withering: Thinly spread the fresh leaves after heat dissipation or dehydration on the bamboo sieve, and turn them every 3 hours; withering is carried out under the slanting sunlight or the weak light of the sunshade roof on a sunny day; the degree of withering is controlled by the green leaves. Yellow-green leaves, evenly and moderatel...

Embodiment 3

[0043] Such as figure 1 Shown, the processing technology of the tealeaves of this embodiment, comprises the steps:

[0044] A. Picking fresh leaves: Picking tea leaves by hand. The fresh leaves are the third level of one bud and three leaves. Keep the fresh leaves intact, fresh and even. ;

[0045] B. Treatment of fresh leaves: spread the fresh leaves thinly in the green storage room to dissipate heat. The green storage room should be clean and the air should be ventilated; if it encounters rain or dew green, it should be dehydrated immediately. Can;

[0046] C. Withering: Thinly spread the fresh leaves after heat dissipation or dehydration on the bamboo sieve, and turn them every 2 hours; withering is carried out under the slanting sunlight or the weak light of the sunshade roof on a sunny day; the degree of withering is controlled by the green leaves Yellow-green leaves, evenly and moderately reveal green fragrance;

[0047] D. Heap green fermentation: Sieve the fresh le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com