A Neutron Poison Encapsulation Particle with Thermal Attachment Properties

A technology of thermal attachment and cladding, applied in the direction of reducing greenhouse gases, climate sustainability, manufacturing reactors, etc., can solve problems such as nuclear material chain reaction loss, and achieve the effect of residence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

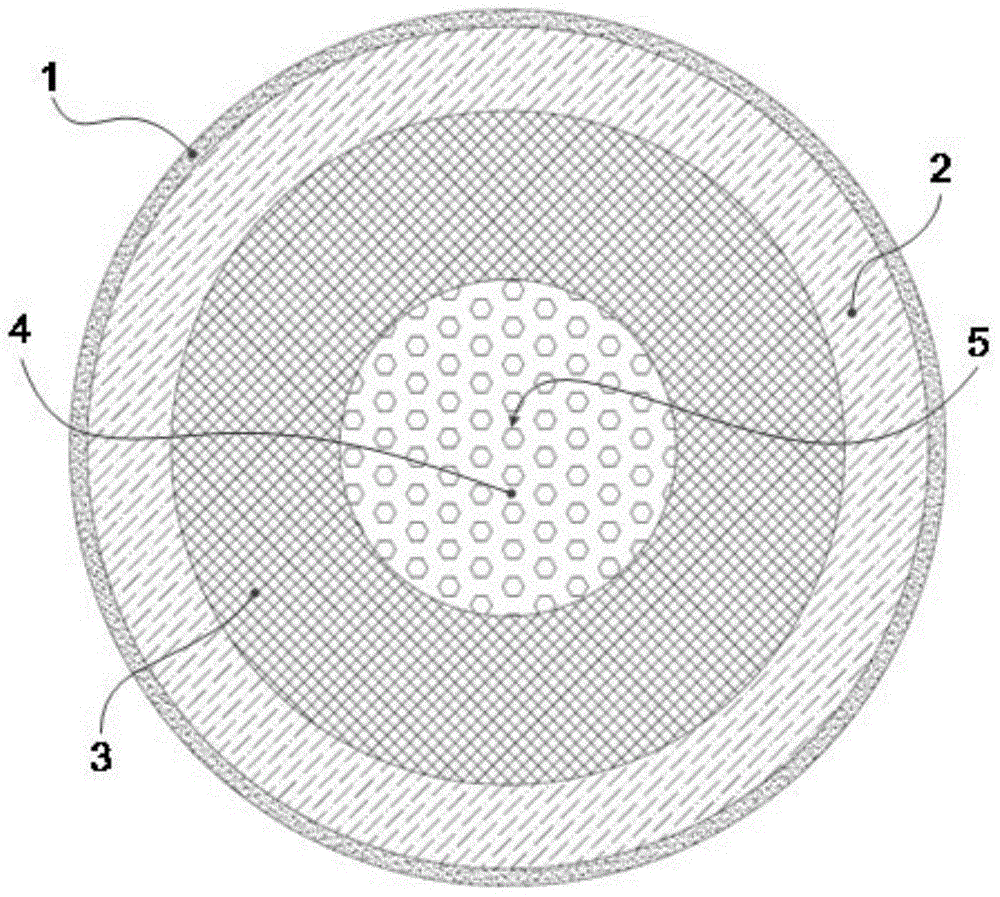

[0017] The outer contour of the neutron poison coating body particles with thermal adhesion characteristics involved in the present invention is spherical, ellipsoidal or capsule-shaped, the particles have a multi-layer shell structure, the central area of the particles is a sphere, and the neutron poison particles are mixed in the material of the spheres 5. Such as figure 1 As shown, taking the coating particle with a spherical outer contour as an example, the outermost shell-like structure of the coating particle is called the particle surface layer 1. Under the condition of meeting the process requirements, the thickness of the particle surface layer 1 is less than that of the coating particle 15% of the radius of a sphere with the same volume, its material will shrink in a high-temperature environment, and cause the surface layer 1 of the parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com