Welding tool of standard knot square frame of construction lift and welding method thereof

A technology for construction elevators and welding tooling, applied in the field of elevators, can solve the problems of high labor cost, efficiency impact, unstable product quality, etc., and achieve the effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

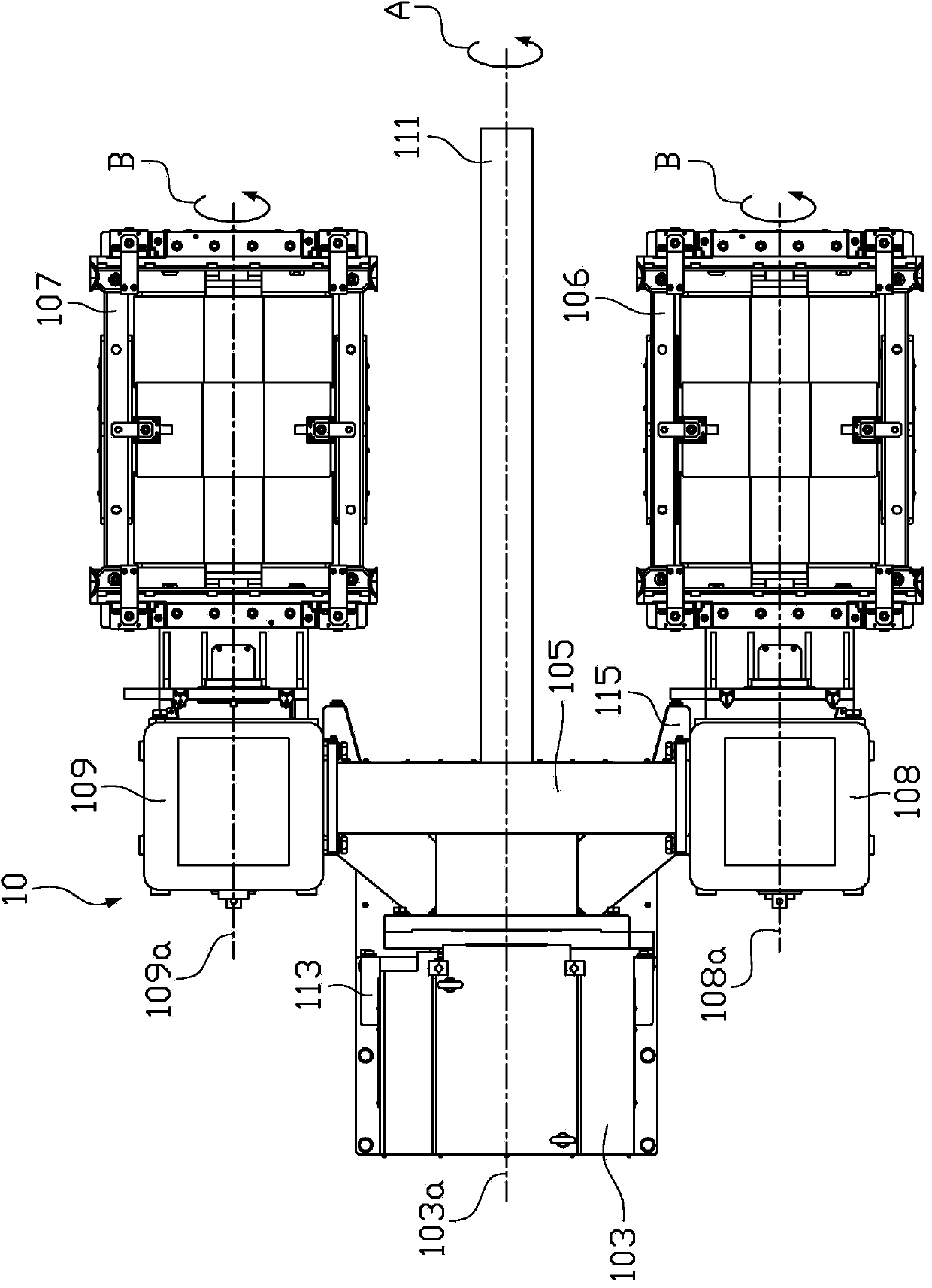

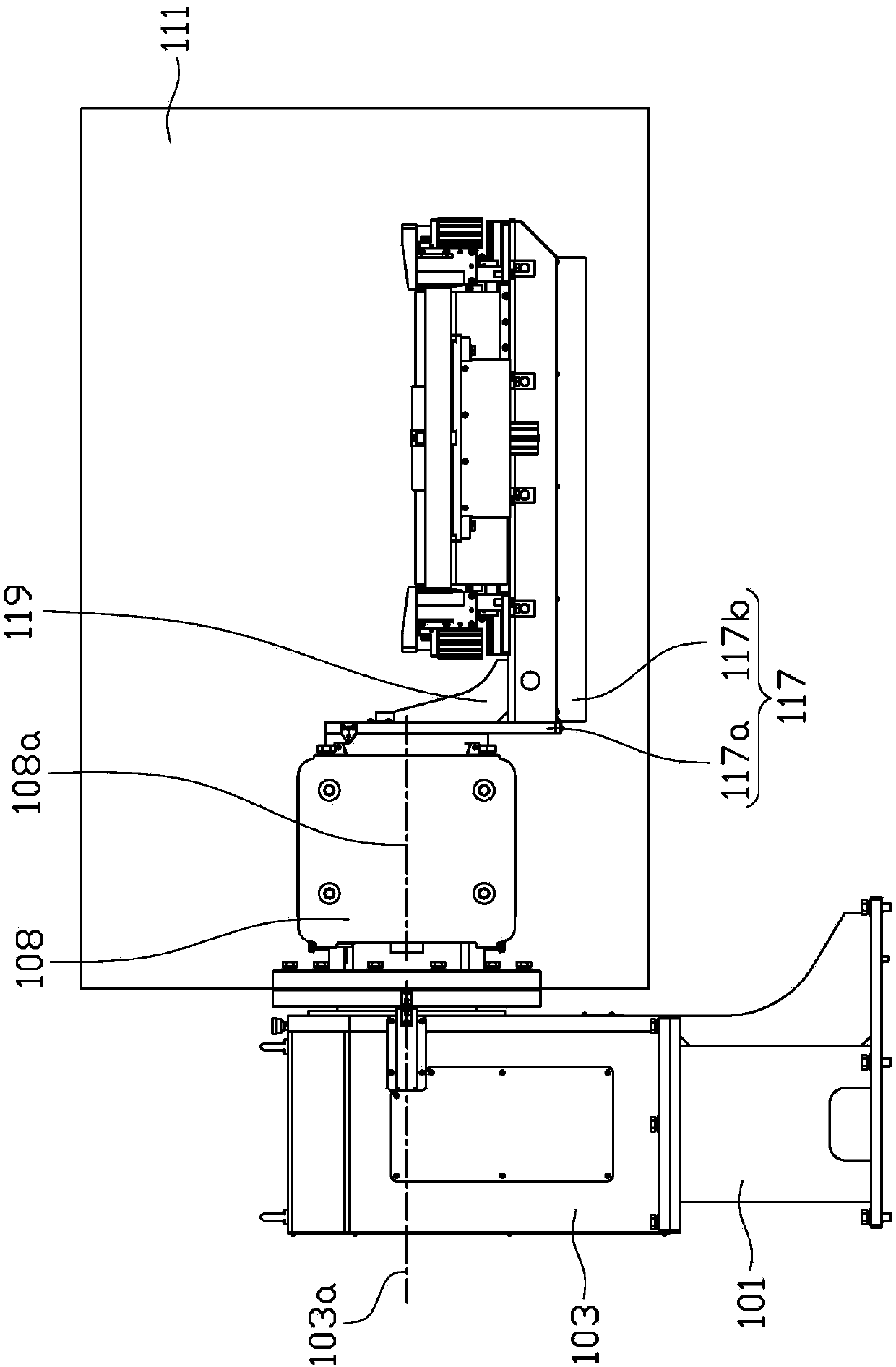

[0025] see figure 1 and figure 2 , the invention discloses a welding tool 10 for a standard section frame of a construction elevator, which is used to automatically weld, for example, a standard section box of a construction elevator, wherein the standard section box is mainly welded from the end to the end of four angle steels into a "mouth" shape.

[0026] The welding tool 10 includes a support 101 , an overturning assembly 103 , a rotating arm 105 , two clamping devices 106 , 107 and two displacement mechanisms 108 , 109 . The turning assembly 103 is installed on the support 101, and the turning assembly 103 has a rotating shaft 103a. The rotating arm 105 is connected to the rotating shaft 103 a of the turning assembly 103 . The two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com