Full-automatic telescopic rotatable camera

A rotating camera and telescopic technology, which is applied in the direction of image communication, TV, color TV parts, etc., can solve the problems of increasing product costs, low camera pixels, and inability to realize Selfie, so as to save production costs and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

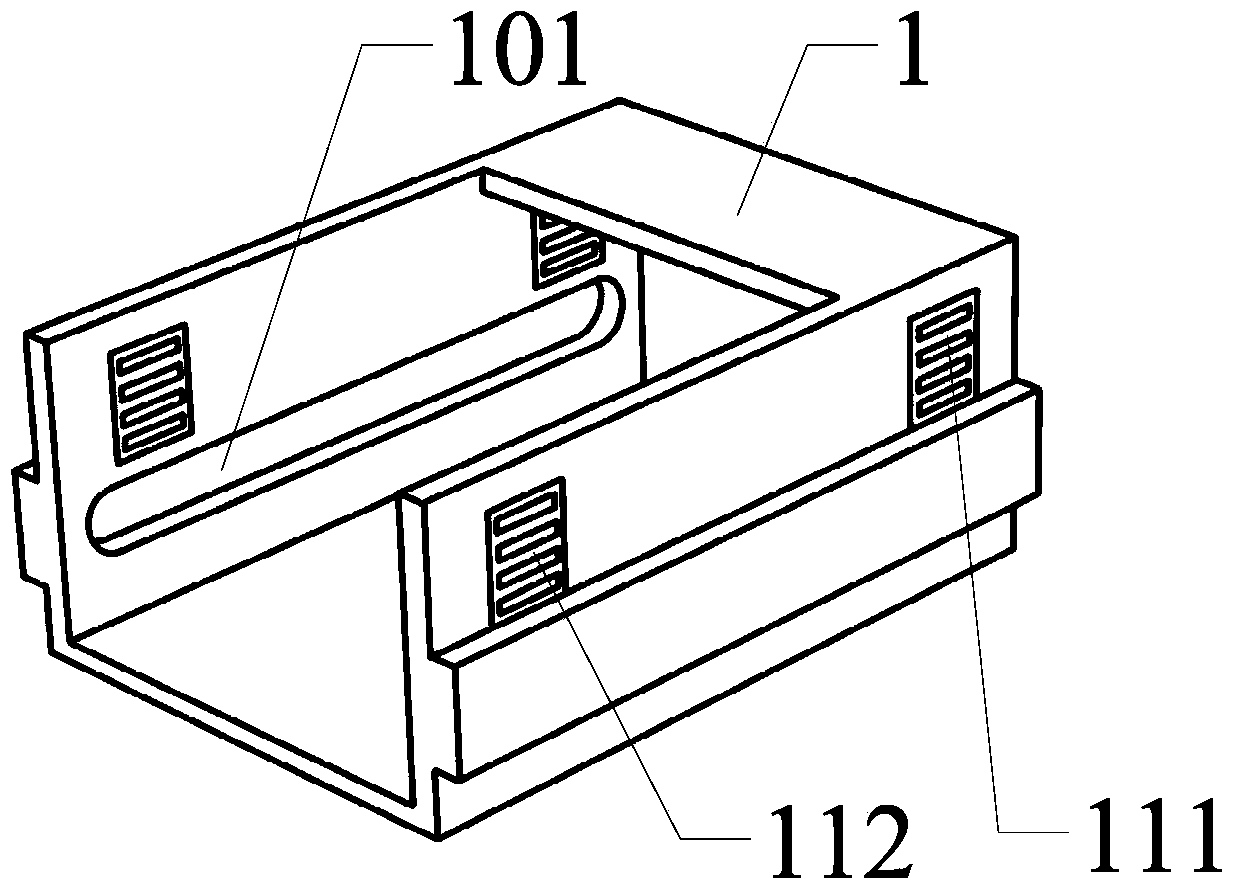

[0043] The fully automatic retractable rotatable camera provided in this embodiment is as follows: figure 1 as shown in:

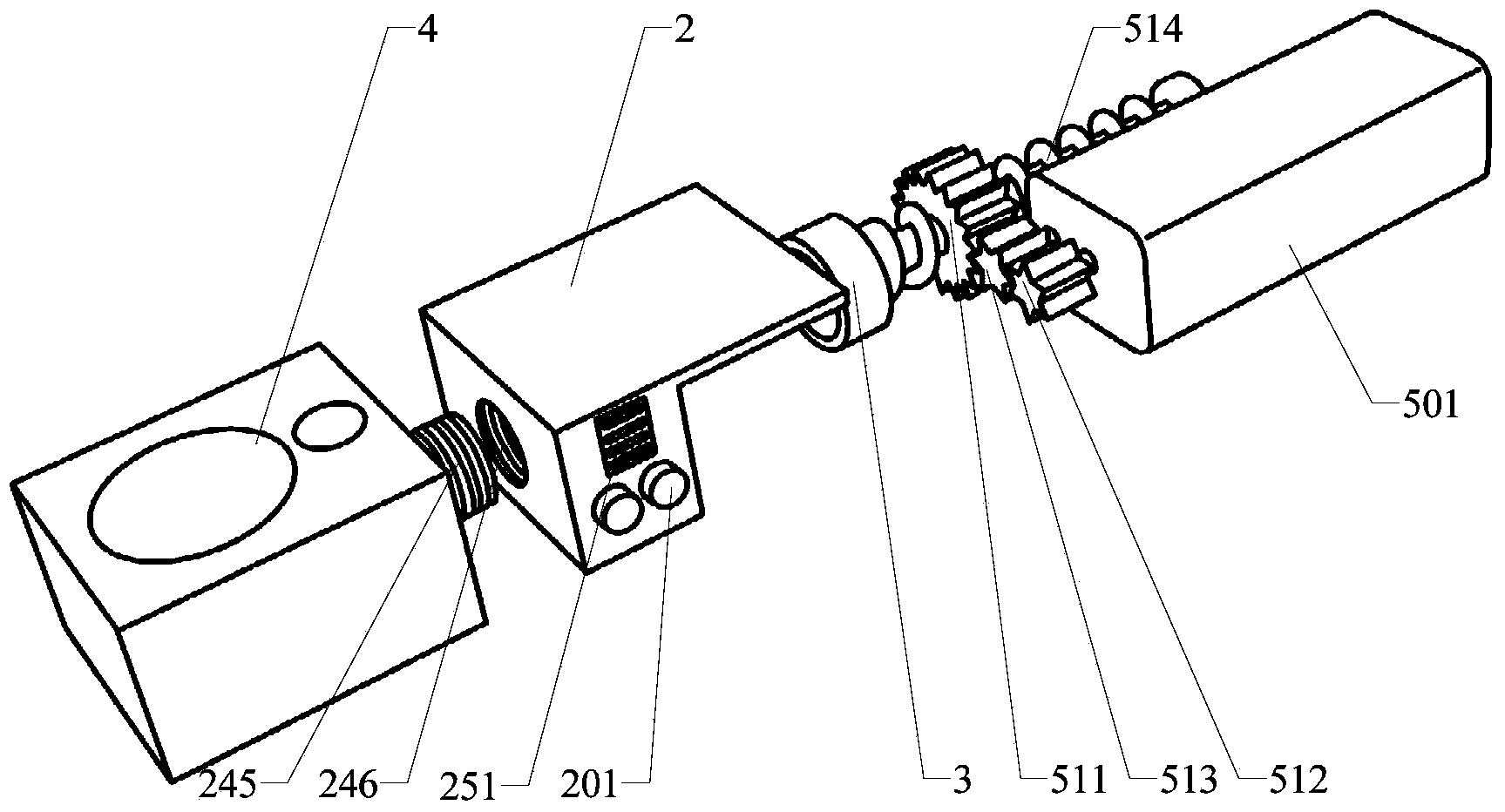

[0044] The fully automatic retractable rotatable camera in this embodiment mainly includes an accommodating space 1 , a connecting assembly 2 , a transmission mechanism, a power motor 501 and the like.

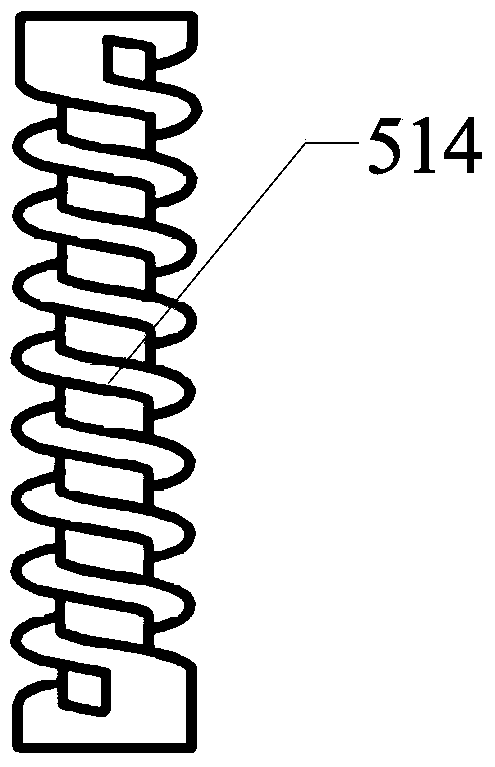

[0045] The transmission mechanism includes a threaded post 514 with a first thread on its surface, and the threaded post 514 is rotatably connected to the connection assembly 2; A gear 511; the first thread is coupled with the second thread.

[0046] The power motor 501 is preferably a stepping motor or other servo motor that can be precisely controlled; the output shaft of the power motor 501 is provided with a second gear 512 .

[0047] In this embodiment, the running plane of the power motor 501 is perpendicular to the moving direction of the camera 4 , that is, the axis of the power motor 501 is parallel to the line where the connecting assembly 2 and ...

Embodiment 2

[0057] The fully automatic retractable rotatable camera provided in this embodiment is as follows: Figure 6 as shown in:

[0058] The fully automatic telescopic and rotatable camera in this embodiment mainly includes an accommodating space 1, a connecting assembly 2, a transmission mechanism, and a power motor 501, etc. The main difference from Embodiment 1 is that the transmission mechanism is different.

[0059] The transmission mechanism in this embodiment mainly includes:

[0060] The transmission mechanism includes a threaded post 514 with a first thread on its surface, and the threaded post 514 is rotatably connected to the connection assembly 2; A gear 511; the first thread is coupled with the second thread.

[0061] The power motor 501 is preferably a stepping motor or other servo motor that can be precisely controlled; the output shaft of the power motor 501 is provided with a second gear 512 .

[0062] In this embodiment, the running plane of the power motor 501 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com