Equipment cabinet, side-hidden type cabinet door component and cabinet door mounting device

A technology for installing devices and cabinet doors, which is applied in the directions of cabinets/boxes/drawer parts, electrical components, electrical equipment casings/cabinets/drawers, etc. Corridor space, to maximize the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

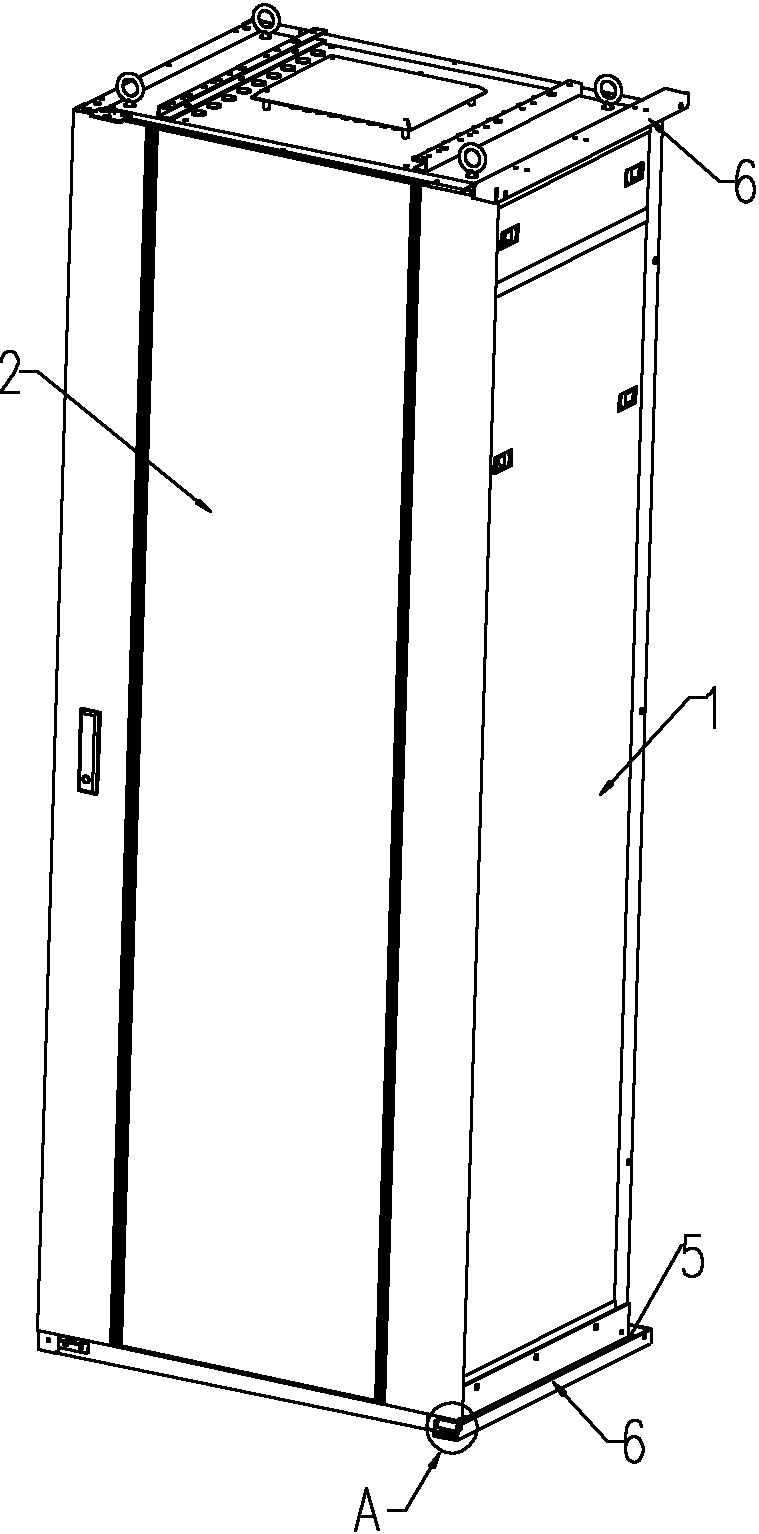

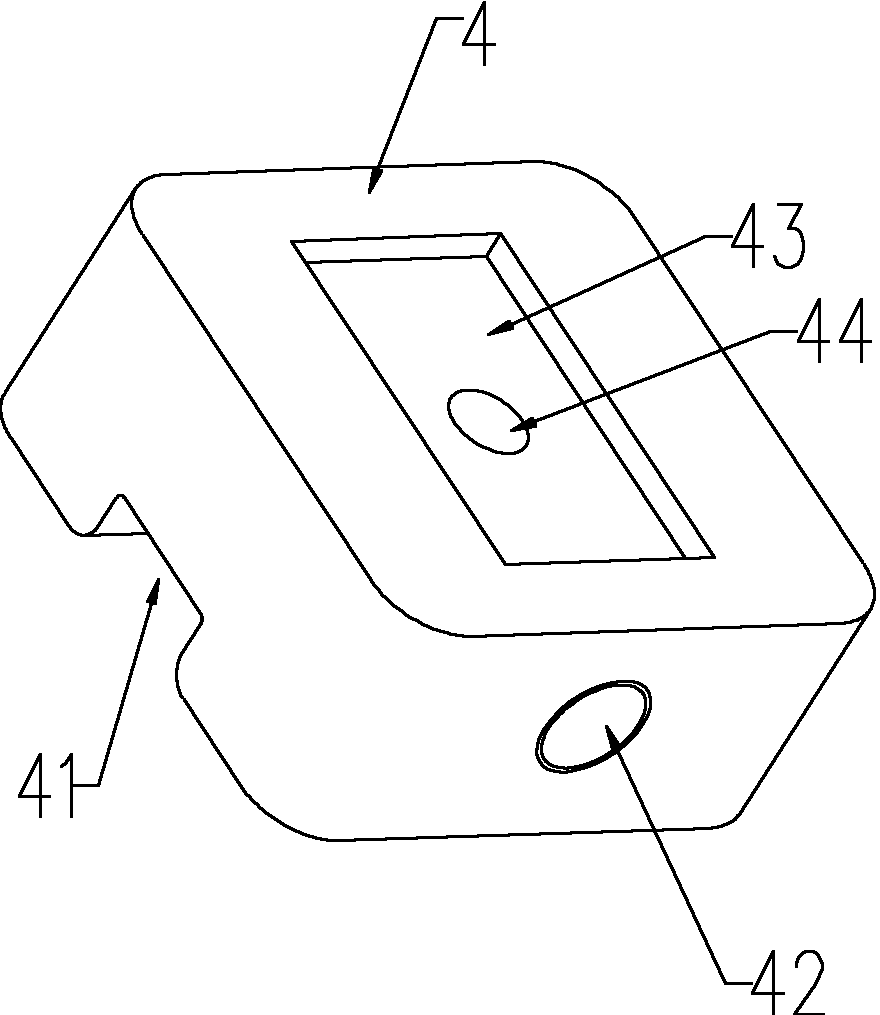

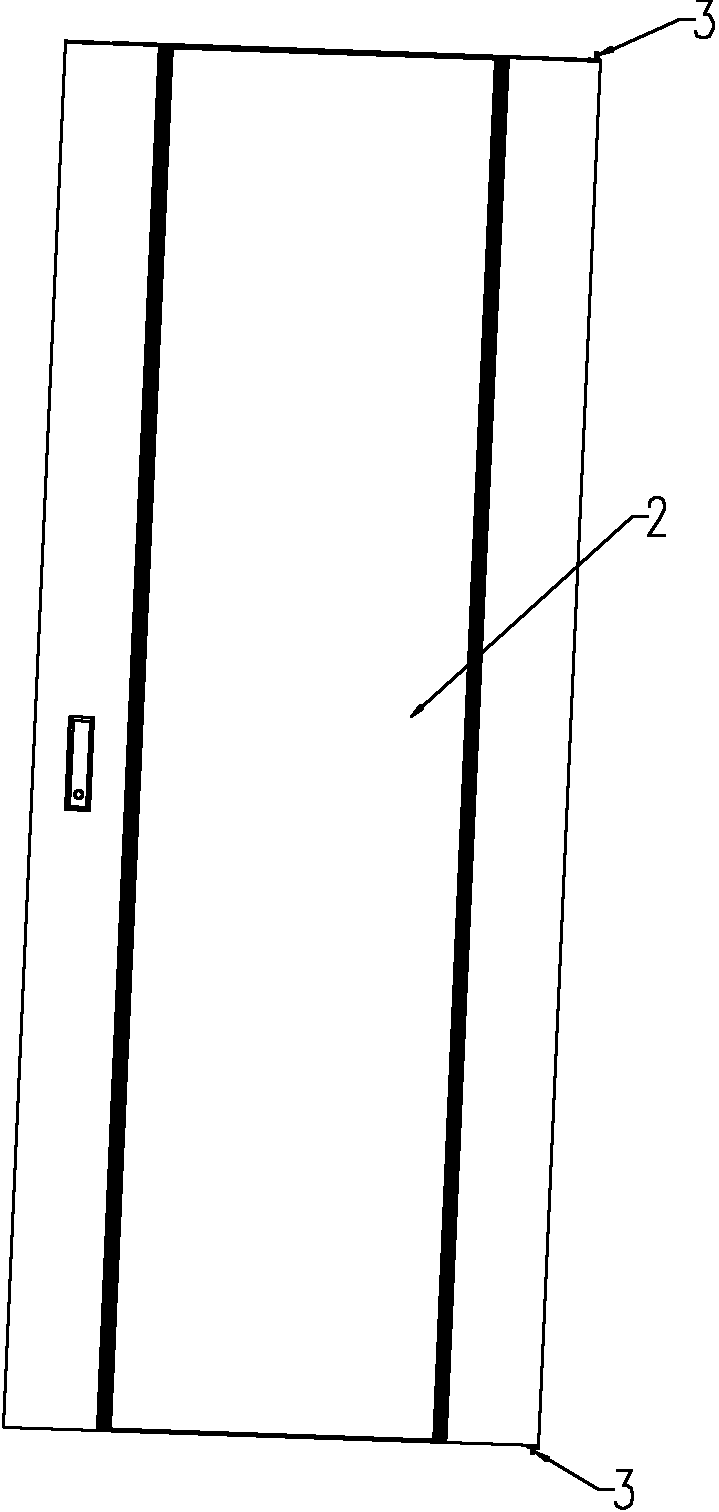

[0028] Embodiment 1 of the cabinet of the present invention, such as Figure 1-7 As shown: the cabinet includes a cabinet body 1, a cabinet door 2 is mounted on the cabinet body 1, a door shaft 3 is arranged on the cabinet door 2, and a guide rail 5 is fixedly installed on the cabinet body, and the guide rail 5 is fixed between the door shaft 3 and the guide rail 5 The direction of extension of the guide fits and rotates around the axis of the door shaft 3. The end of the door shaft 3 is provided with a slide block 4, the door shaft 3 is rotatably assembled on the slide block 4, and the door shaft 3 and the guide rail 5 are rotatably matched by the slide block 4. One of the slider 4 and the door shaft 3 is provided with a corner limiting groove, and the other is provided with a corner limiting block for cooperating with the corner limiting groove to limit the rotation angle of the door shaft. The cabinet body is also fixedly equipped with a slideway 6 that is used to install ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com