Method for controlling roll gap during finish rolling of strip steel

A control method and roll gap technology, which is applied in the direction of rolling force/roll gap control, etc., can solve the problems of roll gap zero point drift and low accuracy of roll gap self-learning model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

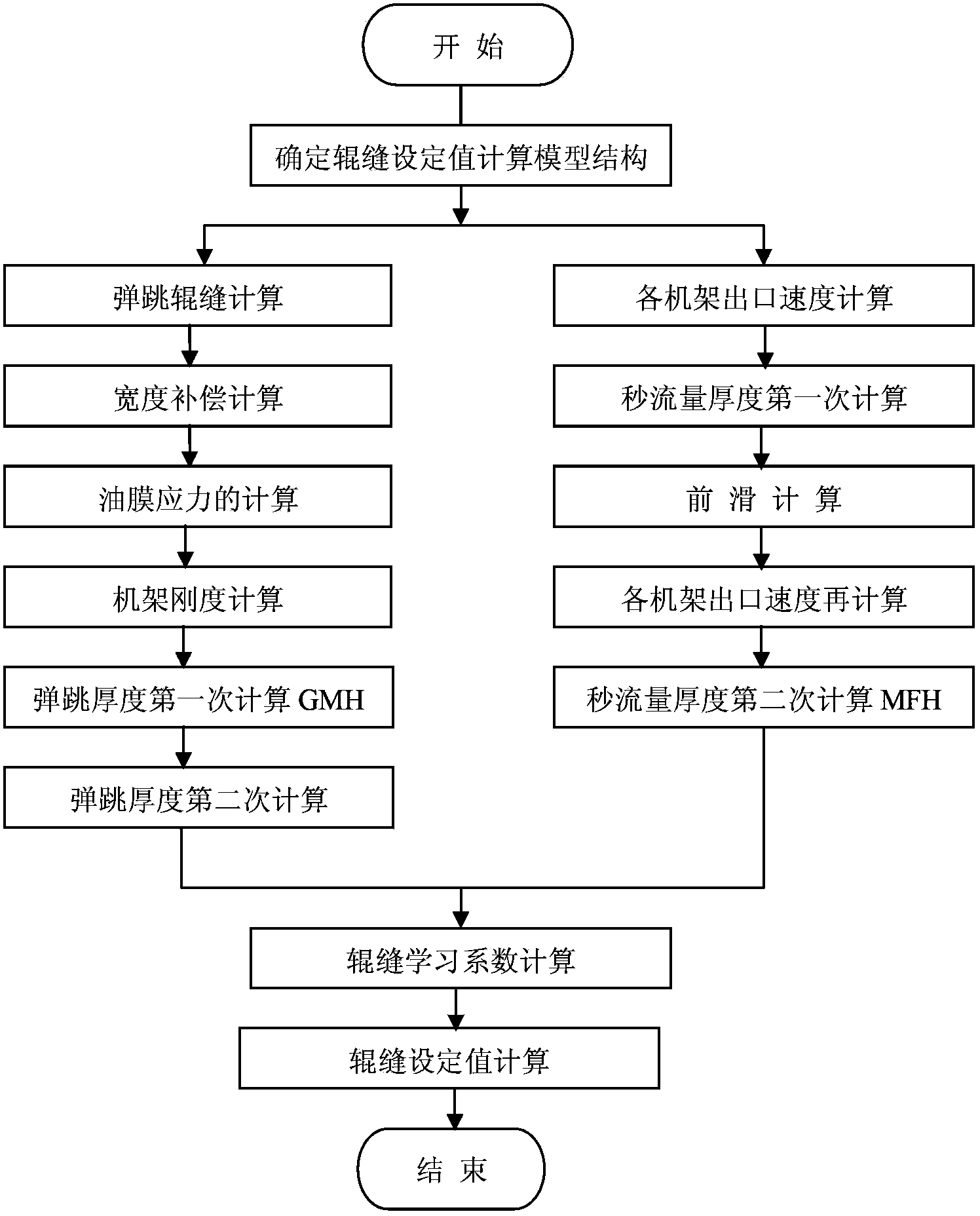

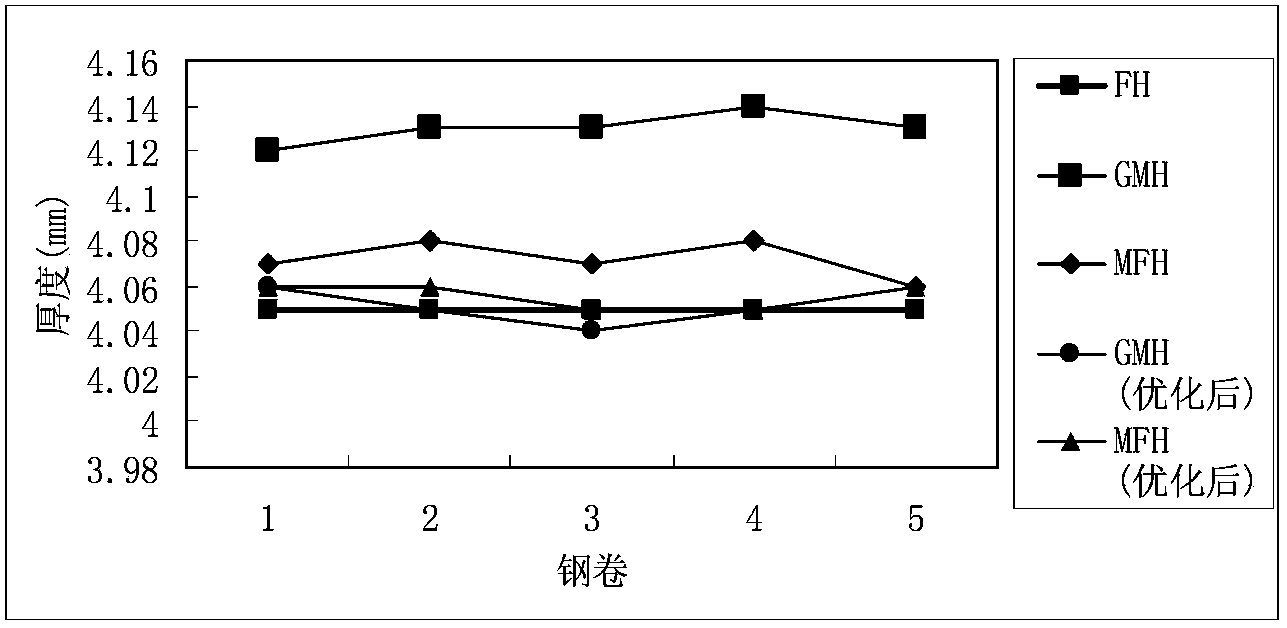

[0062] The steel types used in this example are SPHC and Q235, which are rolled on a 1780mm hot rolling mill. The thickness of the finished product is 3.5~6mm, the width of the finished product is 1042~1252mm, and the final rolling temperature is 880°C. Such as figure 2 As shown in , the implementation steps are as follows:

[0063] (1) Determine the new roll gap setting model structure

[0064] According to the derivation process mentioned in the technical solution, a new calculation model for roll gap setting is obtained, namely formula (10):

[0065] G a p = F h ? (S-S ) j *Gwid 100 * W C X + ( S 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com