Bending device and component mounting device

A technology of a bending device and an installation device, applied in the field of bending, can solve the problems of insufficient lead bending, improper contact between the lead and the bending device, and inability to install lead components reliably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

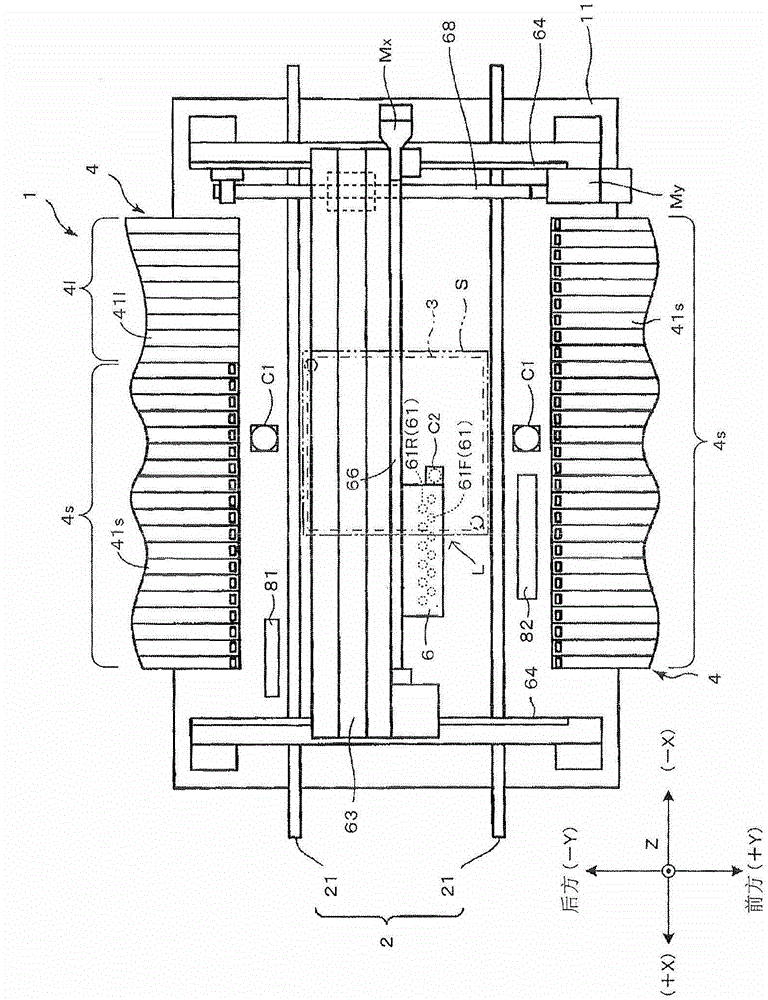

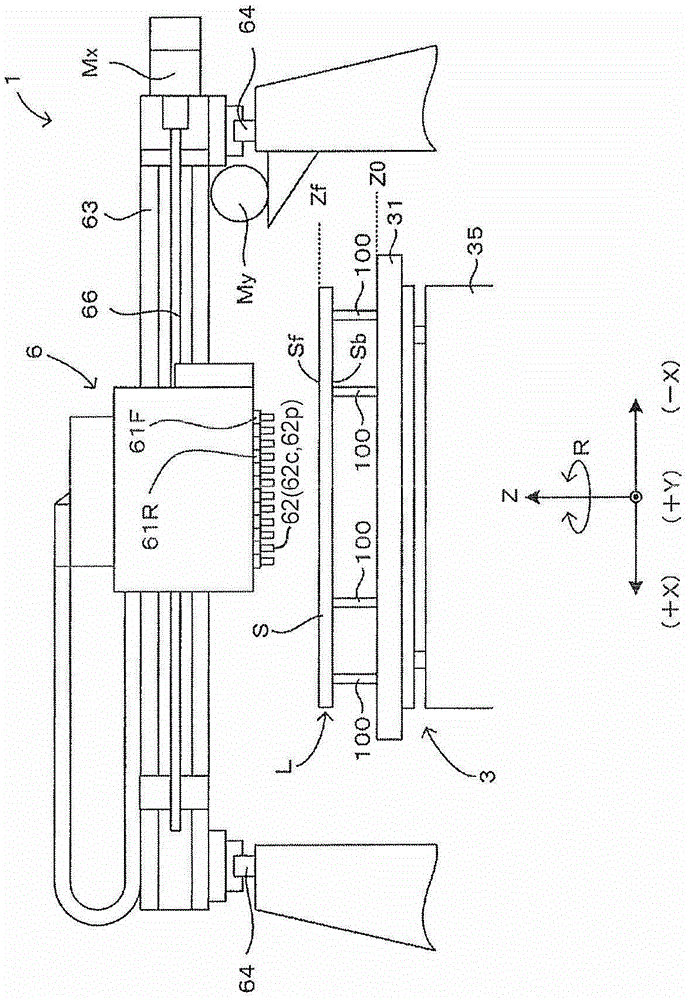

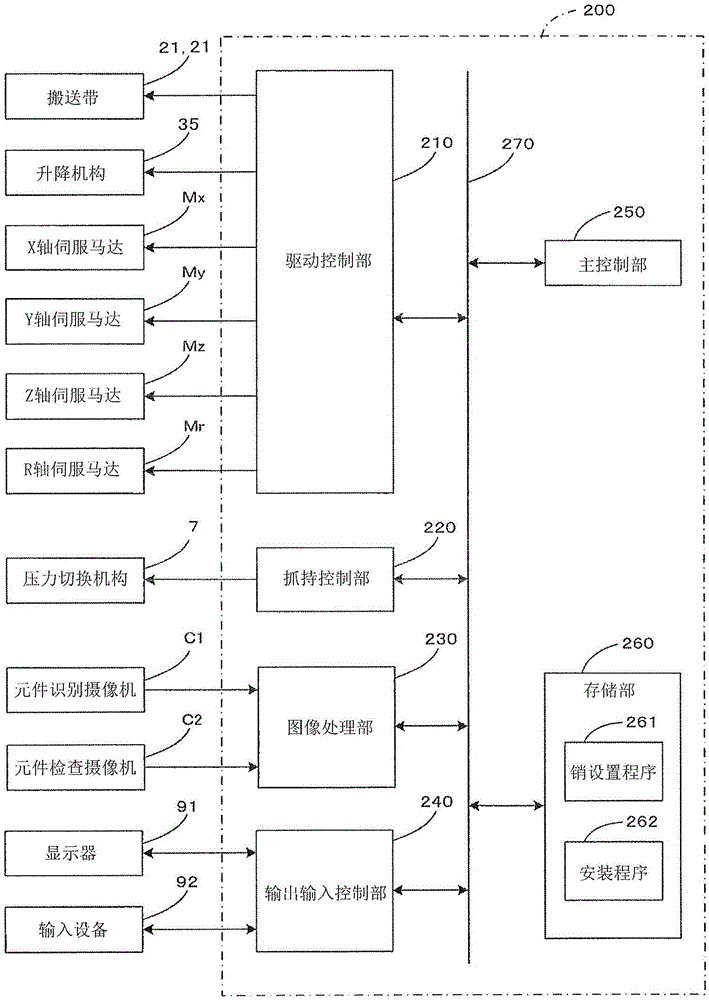

[0016] figure 1 It is a plan view showing the schematic structure of the component mounting apparatus 1 according to the embodiment of the present invention, figure 2 is a partial front view of the component mounting device 1, image 3 It is a block diagram showing the main electrical configuration of the component mounting device 1 . The component mounting apparatus 1 shown in these figures has a structure capable of mounting both surface mount components and lead components P1 on the substrate S. In addition, in figure 1 , figure 2 In the drawings shown below, in order to clarify the directional relationship in each drawing, XYZ orthogonal coordinate axes with the Z-axis direction as the vertical direction are appropriately shown.

[0017] The component mounting apparatus 1 includes a base 11 and a substrate conveyance mechanism 2 provided on the base 11 , and can convey a substrate S in a predetermined conveyance direction X. More specifically, the substrate transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com