Centrifugal fan

A centrifugal fan and fan blade technology, which is applied to the components of the pumping device for elastic fluids, non-variable pumps, machines/engines, etc., can solve problems such as noise and centrifugal fan pressure loss, and avoid Pressure loss, noise reduction, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

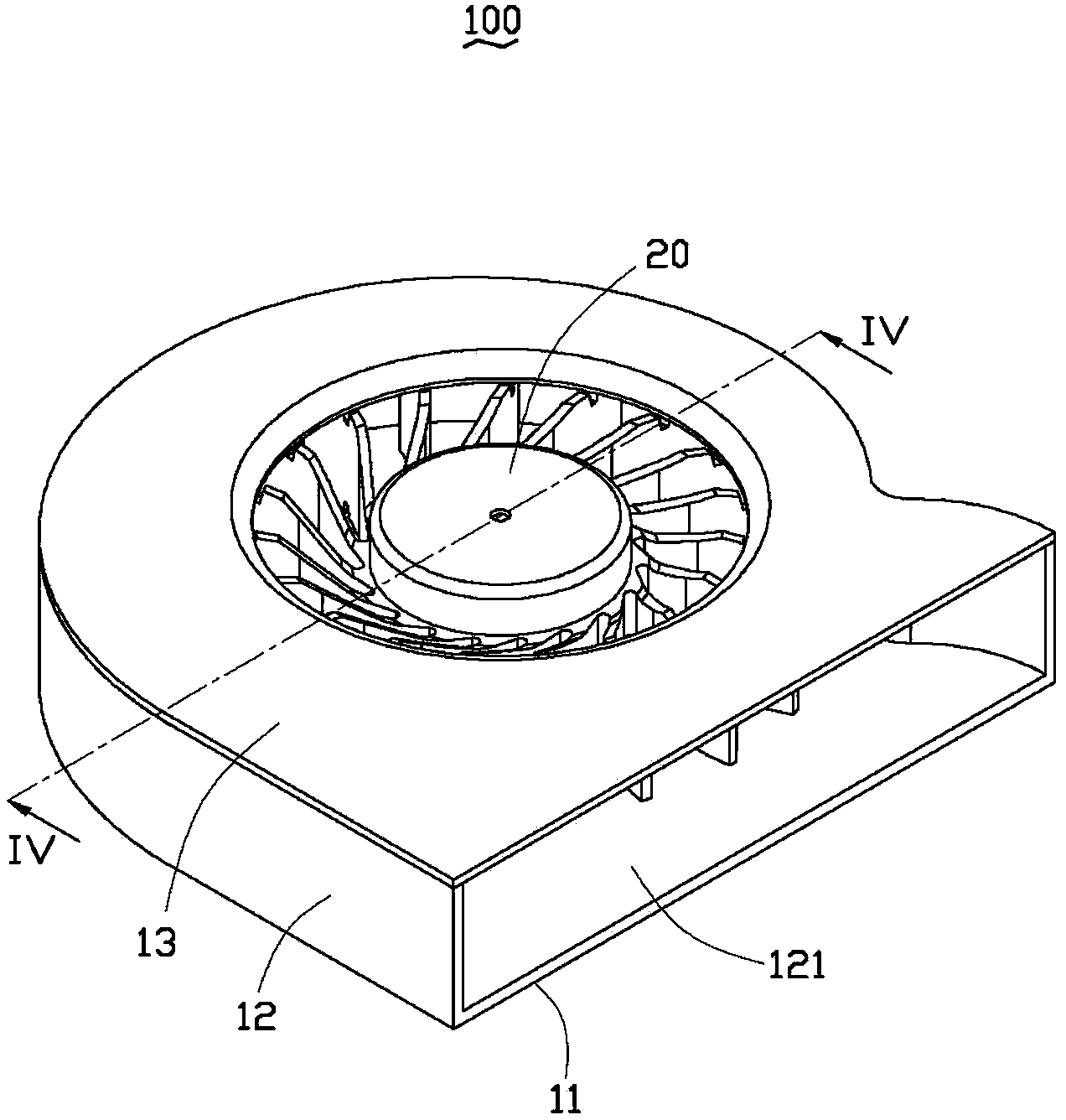

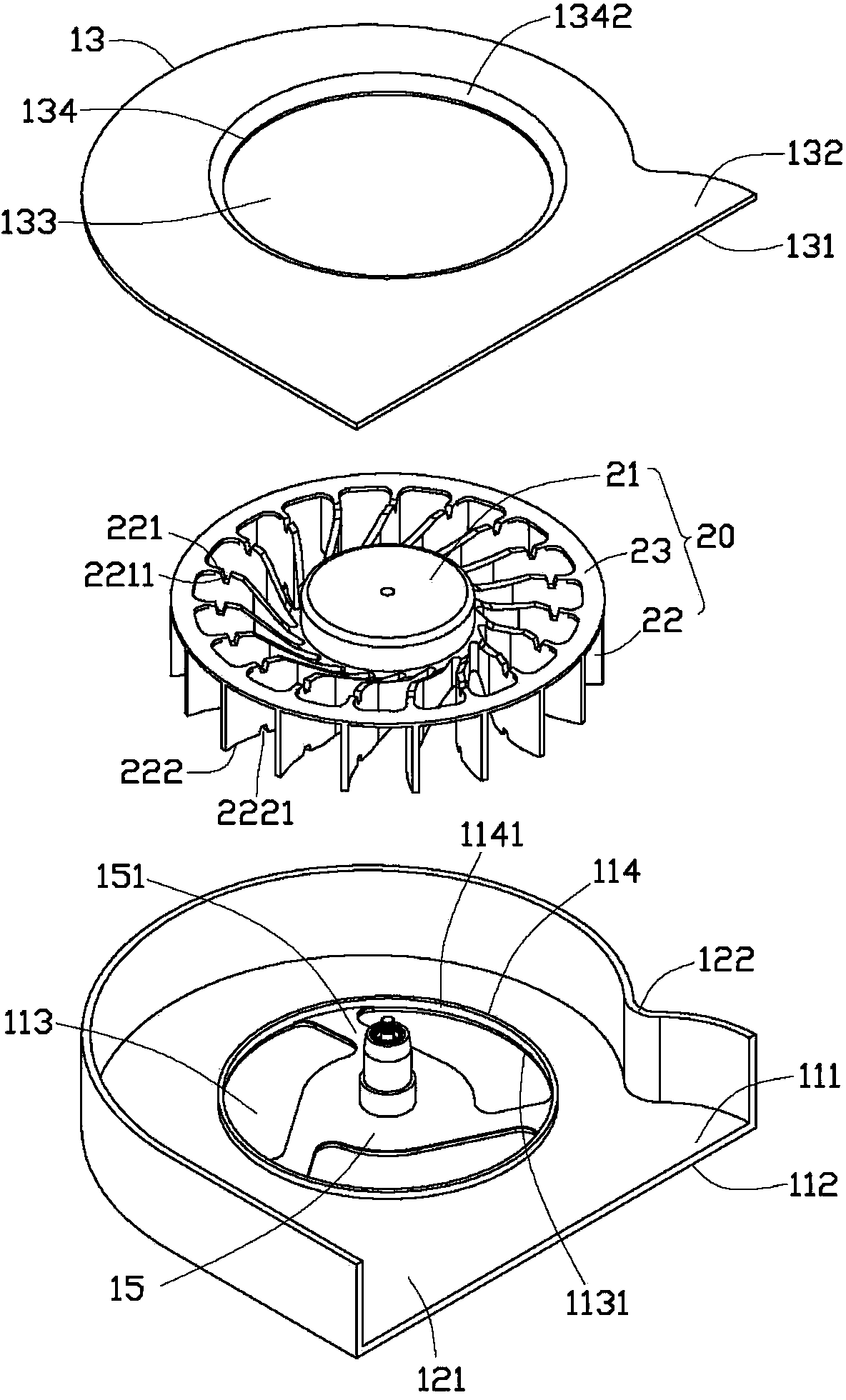

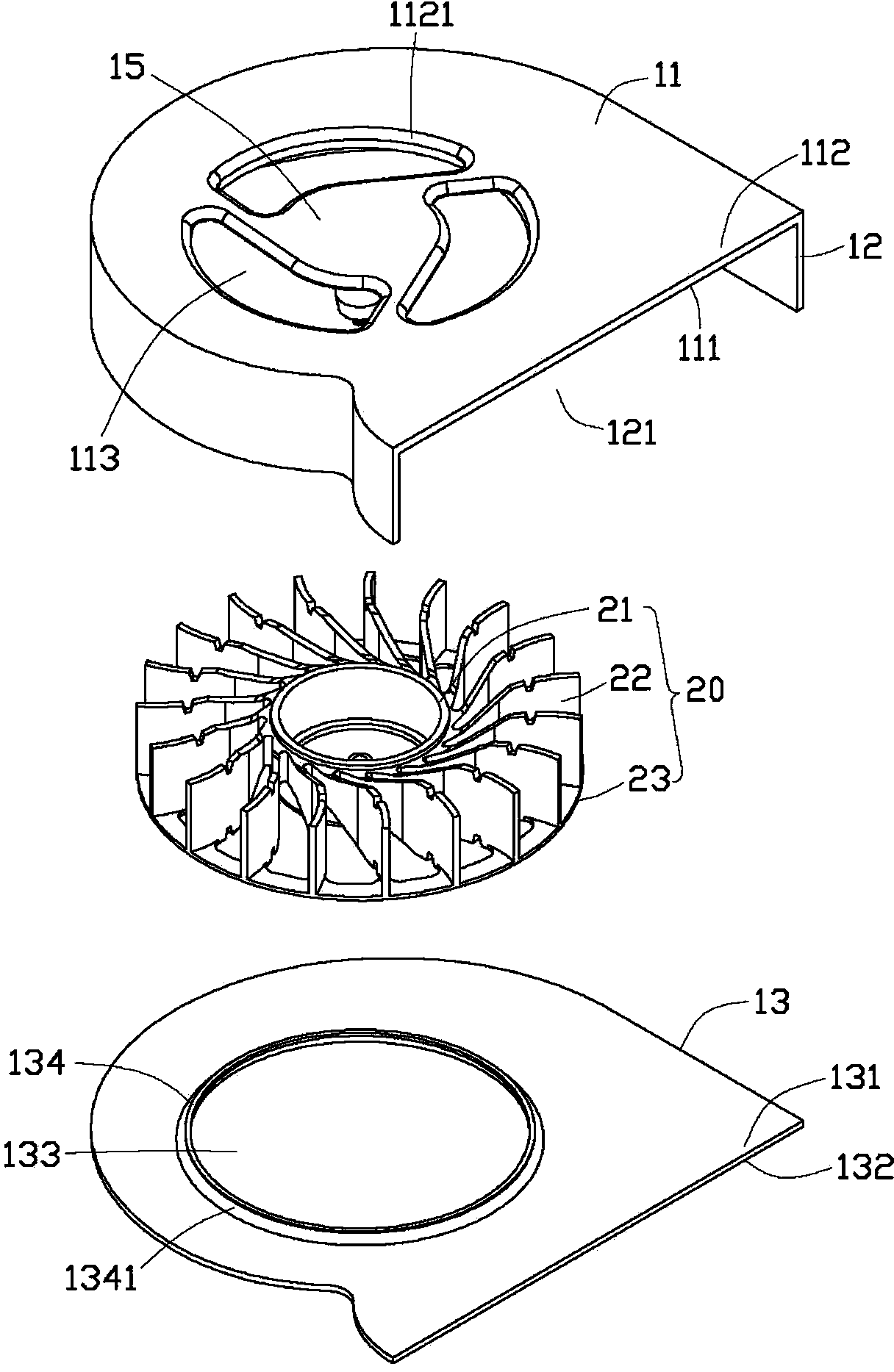

[0015] see Figure 1 to Figure 4 , is a centrifugal fan 100 according to the first embodiment of the present invention, and the centrifugal fan 100 includes a fan frame 10 and an impeller 20 accommodated in the fan frame 10 .

[0016] The fan frame 10 includes a bottom plate 11 , a side plate 12 extending upward from a periphery of the bottom plate 11 , and a cover plate 13 covering a top end of the side plate 12 . The base plate 11 , the side plate 12 and the cover plate 13 together form a receiving space 14 for receiving the impeller 20 .

[0017] The bottom plate 11 includes an inner surface 111 facing the impeller 20 and an outer surface 112 opposite to the inner surface 111 and facing away from the impeller 20 . The side plate 12 is located on a side where the inner surface 111 is located. A fixing seat 15 is disposed in the middle of the bottom plate 11 , and three first air inlets 113 are formed on the outer periphery of the fixing seat 15 in the middle of the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com