Power battery cooling control method based on power battery cooling control system

A cooling control and power battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of uniformity of flow field, inconsistency of internal resistance of lithium-ion power battery cells, inaccurate temperature detection, and uneven temperature, etc. Achieve the effect of overcoming the limitations of temperature and space conditions, ensuring the consistency of internal resistance, and extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

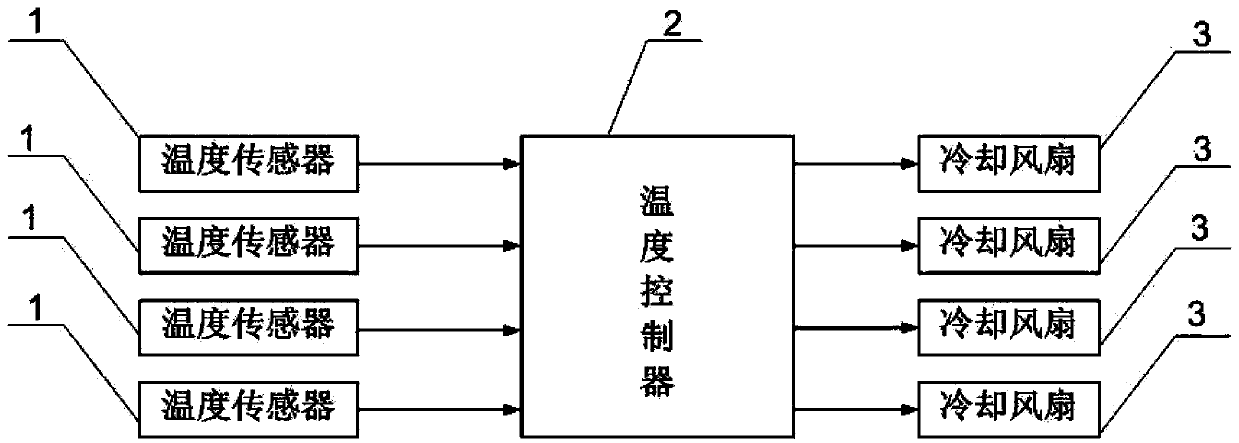

[0016] Such as figure 1 As shown, a power battery cooling control system includes n temperature sensors 1, a temperature controller 2 and a cooling fan 3 installed in the lithium-ion power battery assembly box of a pure electric vehicle, where n is a positive integer greater than or equal to 2; The temperature sensor 1 is used to detect the temperature of each battery cell inside the box of the power battery pack assembly, the output end of the temperature sensor 1 is connected to the input end of the temperature controller 2, and the output end of the temperature controller 2 Connect the control signal input end of the motor of the cooling fan 3 . Four temperature sensors are included in this embodiment.

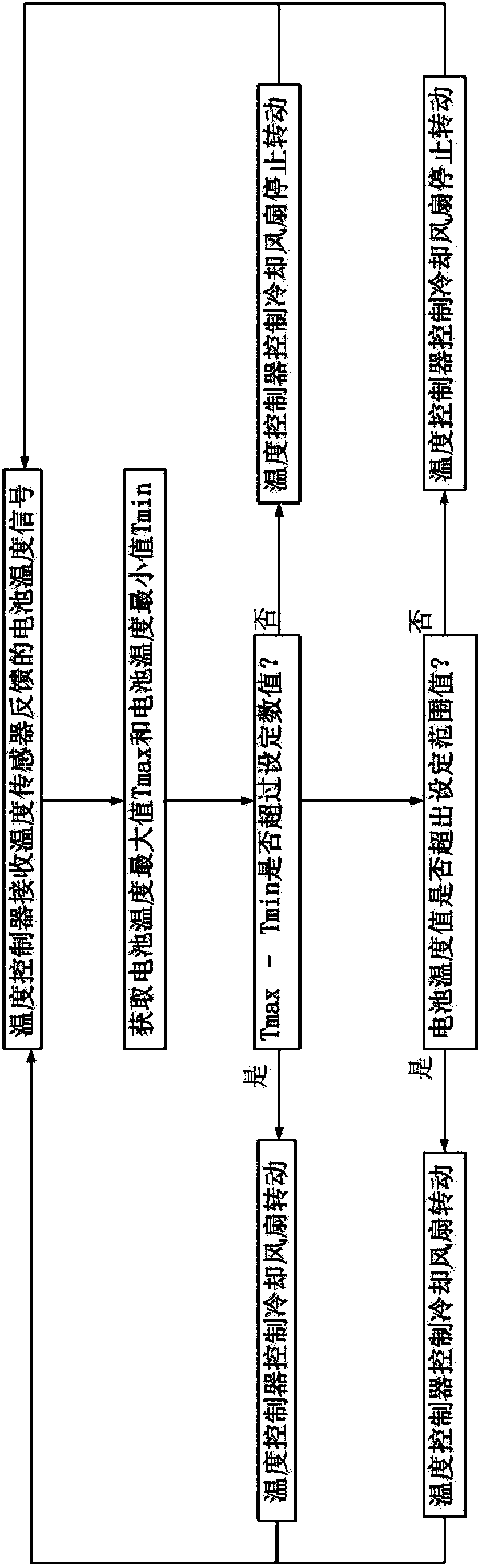

[0017] Such as figure 2 As shown, a power battery cooling control method based on a power battery cooling control system includes the following steps:...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap