Loading and unloading process for cross-sea container and container loading and unloading system with cross-sea trestle

A technology for loading and unloading systems and containers, applied in bridges, transportation and packaging, walking bridge cranes, etc., can solve the problems of low loading and unloading process efficiency, low process efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

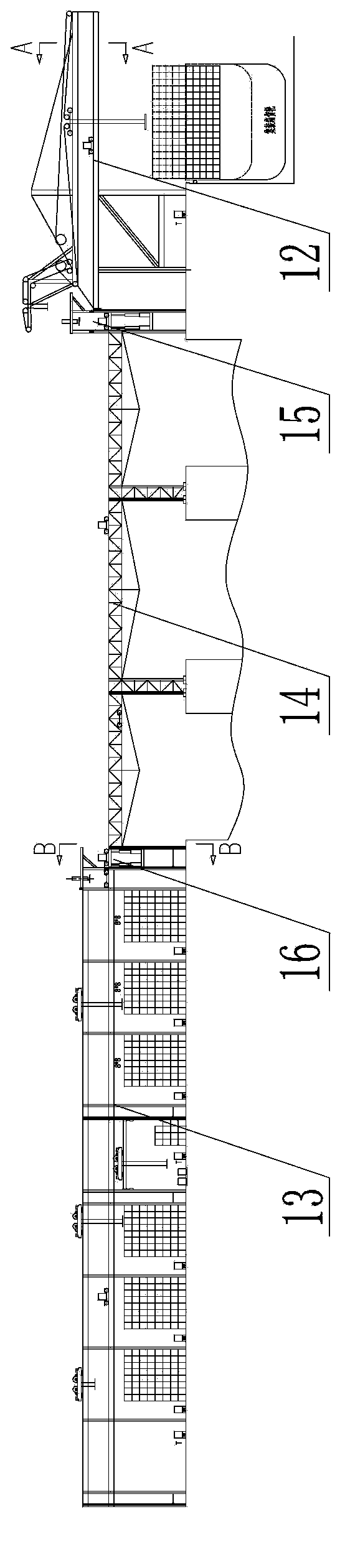

[0037] Embodiment 1 of the present invention, a sea-crossing container loading and unloading process, comprises the following steps:

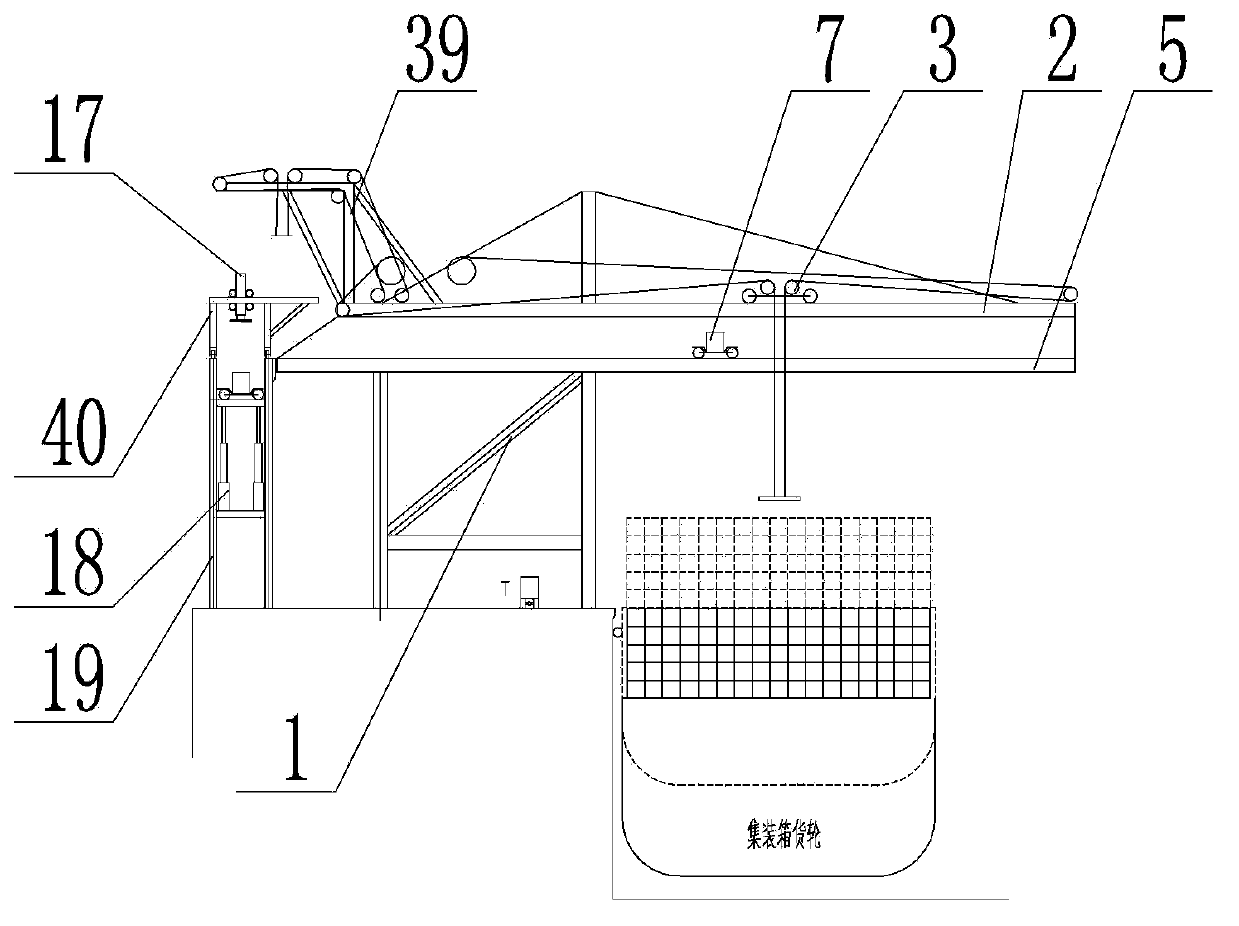

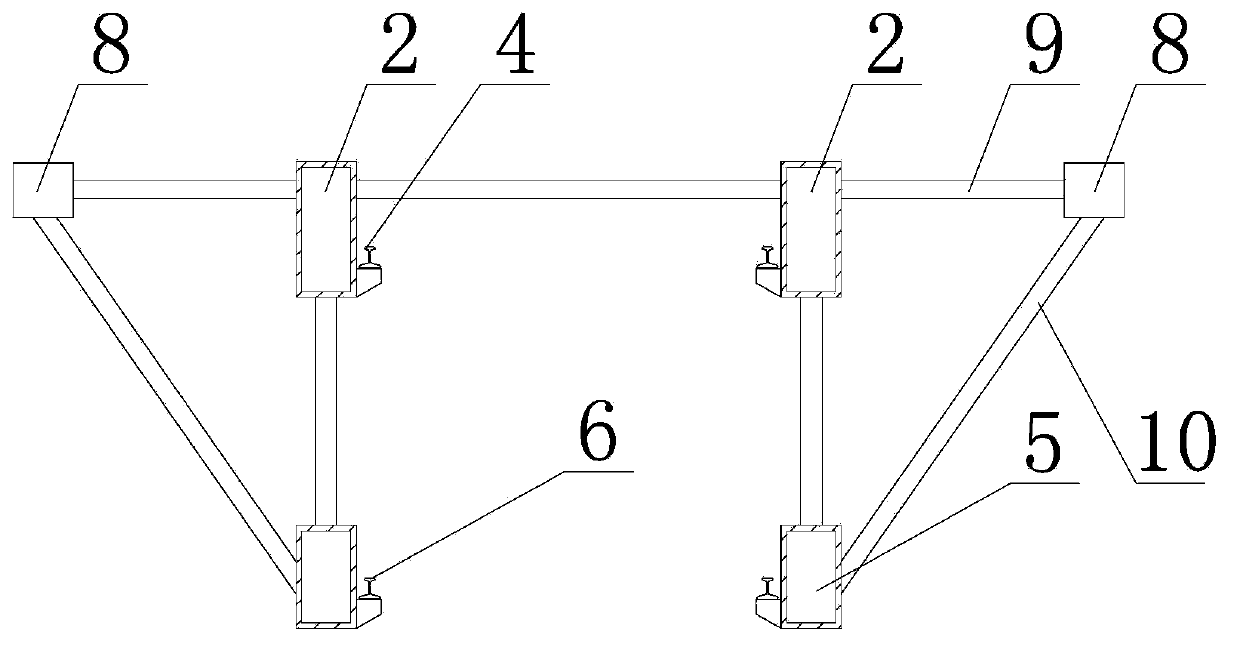

[0038] (a) The quay crane lifts and transfers the container, the spreader of the quay crane trolley lowers and grabs the container, lifts the container to a height above the quay crane transfer trolley below, and the quay crane transfer trolley runs to the container and stops directly below, The lifting trolley puts the container on the quayside crane transfer trolley and lifts it away. The quayside crane transfer trolley car box drives to the quayside bridge ferry bridge. While the quayside bridge transfer trolley car box drives to the quayside bridge ferry bridge, the lifting trolley starts to grab next container;

[0039] (b) The container is transferred on the quayside bridge ferry bridge, the quayside bridge transfer trolley drives to the crotch of the quayside bridge ferry bridge and stops, the lifting device A on the quayside bridge ferr...

Embodiment 2

[0051] Embodiment 2 of the present invention, a sea-crossing container loading and unloading process, comprises the following steps:

[0052] (a) The quay crane lifts and transfers the container, the spreader of the quay crane trolley lowers and grabs the container, lifts the container to a height above the quay crane transfer trolley below, and the quay crane transfer trolley runs to the container and stops directly below, The lifting trolley puts the container on the quayside crane transfer trolley and lifts it away. The quayside crane transfer trolley car box drives to the quayside bridge ferry bridge. While the quayside bridge transfer trolley car box drives to the quayside bridge ferry bridge, the lifting trolley starts to grab next container;

[0053] (b) The container is transferred on the quayside bridge ferry bridge, the quayside bridge transfer trolley drives to the crotch of the quayside bridge ferry bridge and stops, the lifting device A on the quayside bridge ferr...

Embodiment 3

[0065] Embodiment 3 of the present invention, a sea-crossing container loading and unloading process, comprises the following steps:

[0066] (a) The quay crane lifts and transfers the container, the spreader of the quay crane trolley lowers and grabs the container, lifts the container to a height above the quay crane transfer trolley below, and the quay crane transfer trolley runs to the container and stops directly below, The lifting trolley puts the container on the quayside crane transfer trolley and lifts it away. The quayside crane transfer trolley car box drives to the quayside bridge ferry bridge. While the quayside bridge transfer trolley car box drives to the quayside bridge ferry bridge, the lifting trolley starts to grab next container;

[0067] (b) The container is transferred on the quayside bridge ferry bridge, the quayside bridge transfer trolley drives to the crotch of the quayside bridge ferry bridge and stops, the lifting device A on the quayside bridge ferr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com