Strip-shaped member anti-hooking device for elevator

A long-shaped and component technology is applied in the field of anti-long-shaped member hooking devices, which can solve the problems of complex structure and difficult installation of the anti-hooking device, and achieve the effects of preventing hooking, simplifying the structure and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

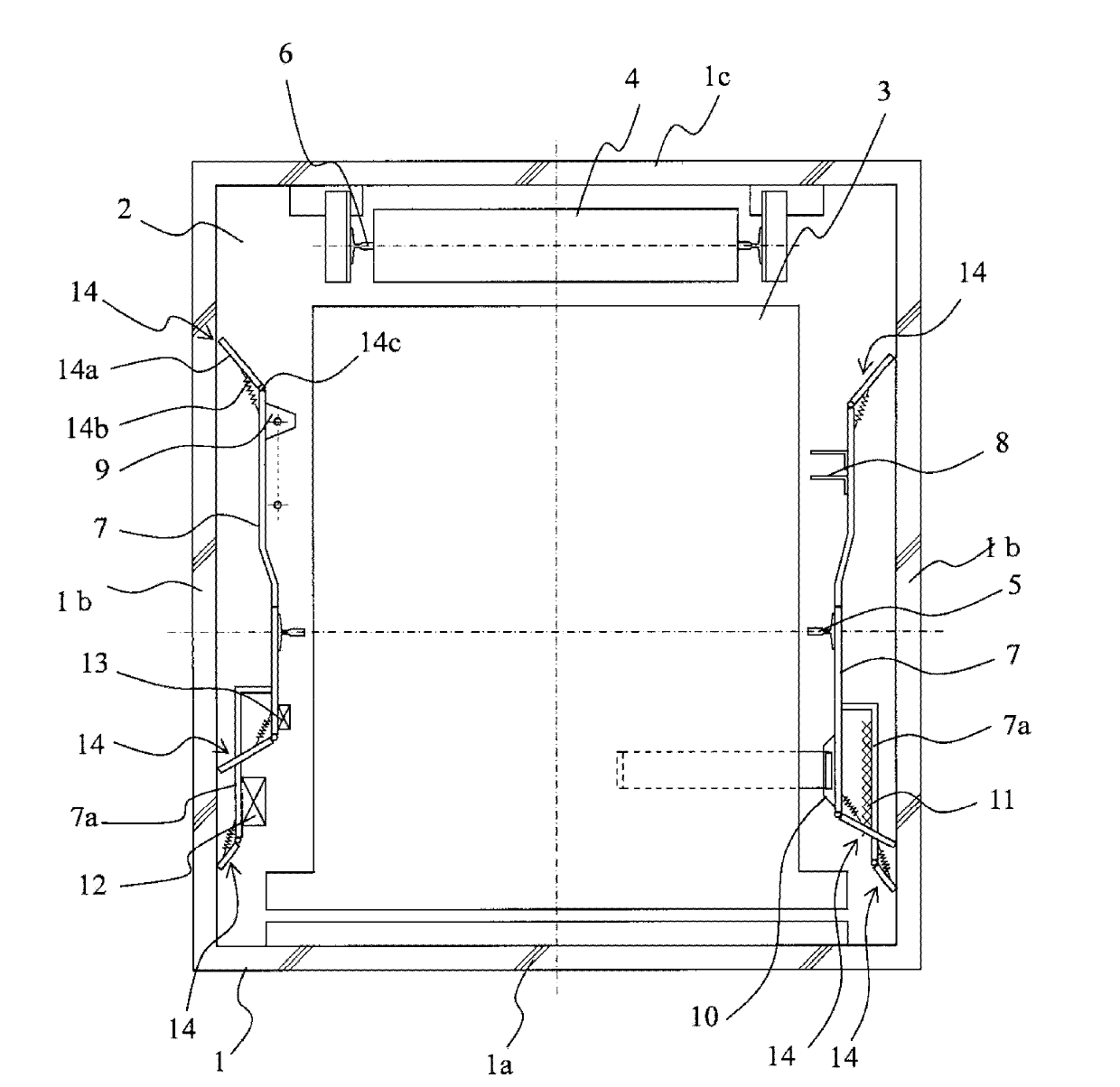

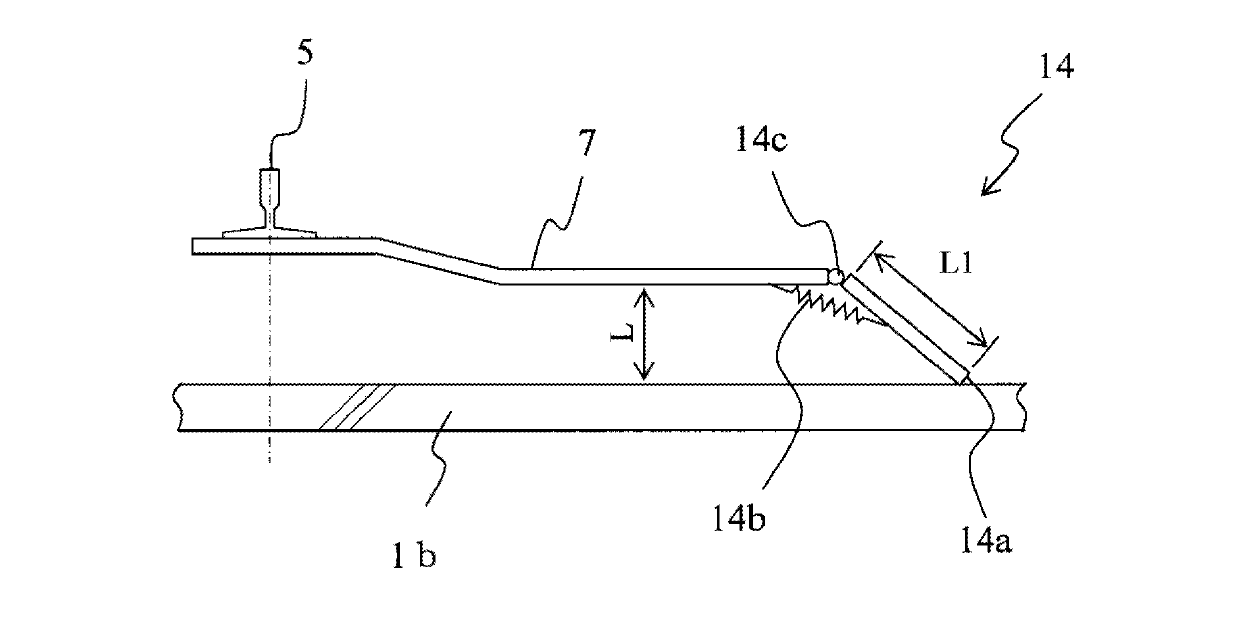

[0043] Such as figure 1 As shown, the elevator has: an elevator passage 2 surrounded by an elevator passage wall 1, that is, a front side wall 1a, a lateral side wall 1b, and a rear side wall 1c; an elevator car 3 and a counterweight 4 ascending and descending in the elevator passage 2; The left and right pair of car guide rails 5 arranged in the hoistway 2 along the vertical direction through the unillustrated guide rail support member arranged on the hoistway wall 1; The guide rail supporting member is arranged on the left and right pair of counterweight guide rails 6 in the hoistway 2 along the up and down direction, and the elevator car 3 moves up and down along the up and down direction under the guidance of the guide rail 5 for the car through the guide shoes not shown in the figure. On the other hand, the counterweight 4 moves up and down in the up-and-down direction under the guidance of the counterweight guide rail 6 through guide shoes (not shown).

[0044] The equi...

no. 2 example

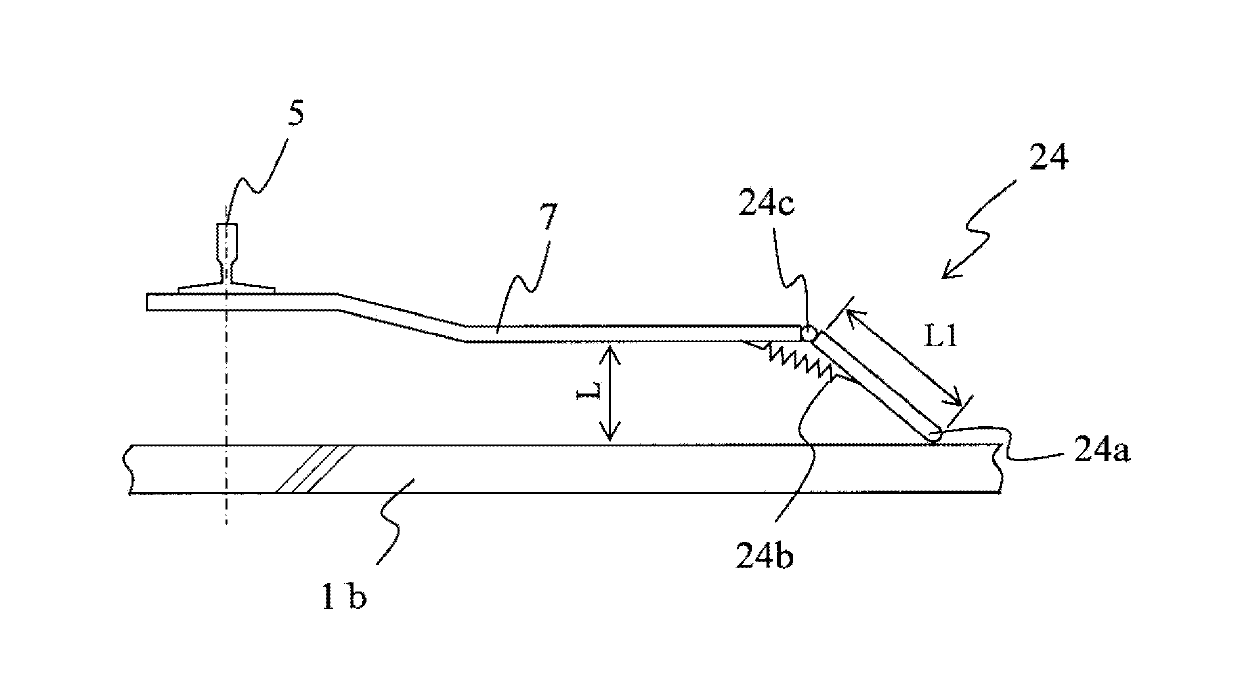

[0055] Refer to the following image 3 A second embodiment of the elevator anti-elongated member hooking prevention device according to the present invention will be described. Parts equivalent to those described above are denoted by the same symbols.

[0056] Such as image 3 As shown, the anti-elongated member hooking device 24 of the second embodiment has a protective member 24a that is rotatably arranged on the end of the equipment support 7 through a hinge 24c and extends toward the hoistway wall 1 and the protective member 24a The end of the member 24a presses the coil spring 24b which is an elastic body on the hoistway wall 1 . Moreover, the end part which abuts the hoistway wall 1 in the protection member 24a has a spherical shape.

[0057] According to the second embodiment, since the end portion of the protective member 24a abutting against the hoistway wall 1 is spherical, even if the hoistway wall 1 is formed of a material that is easily damaged such as glass, t...

no. 3 example

[0059] Refer to the following Figure 4 A third embodiment of the elevator anti-elongated member hooking prevention device according to the present invention will be described. Parts equivalent to those described above are denoted by the same symbols.

[0060] Such as Figure 4 As shown, the anti-elongated member hooking device 34 of the third embodiment has a protective member 34a that is rotatably arranged on the end of the equipment support 7 by a hinge 34c and extends toward the hoistway wall 1 and the protective member 34a The end of the member 34a presses the coil spring 34b which is an elastic body on the hoistway wall 1 . In addition, rollers 34d are provided on the ends of the protective members 34a that abut against the hoistway wall 1 .

[0061] According to the third embodiment, since the end portion of the protective member 34a abutting against the hoistway wall 1 is provided with a roller 34d, even if the hoistway wall 1 is formed of easily damaged materials s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com