Nylon wire feeding mechanism of nylon wire bonding device

A technology of sticking wool and wire inlet, applied in stringed instruments, instruments, etc., can solve the problems of falling off the wool, affecting the use function, not standard enough, etc., to achieve the effect of simple and efficient bonding process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

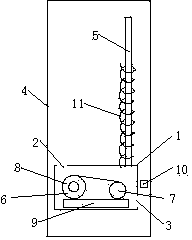

[0010] Combine below figure 1 Specific description embodiment:

[0011] A wire inlet mechanism for a woolen sticking device, comprising a housing 1, characterized in that one end of the housing 1 is provided with a wire inlet 2, and the other end of the housing 1 is provided with a wire outlet 3, so One end of the housing 1 located at the wire inlet 2 is hinged to the base 4, one end of the housing 1 located at the wire outlet 3 is connected with a push rod 5, and the housing 1 is provided with a driving guide wheel 6 and the driven guide wheel 7, the driving guide wheel 6 and the driven guide wheel 7 are connected by a belt, the driving guide wheel 6 is connected with a motor 8, and the lower part of the housing 1 is provided with a cam plate 9, the convex plate 9 is attached to the lower part of the driving guide wheel 6 and the driven guide wheel 7, and the push rod 5 is provided with a spring 11.

[0012] Preferably, the base 4 is provided with a limiting plate 10 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com