Internal inflow stepped screen board grid cleaner

A step-type, decontamination machine technology, applied in the direction of filtration separation, separation method, mobile filter element filter, etc., can solve the problem of secondary pollution, etc., and achieve the effect of large overflow, high safety factor and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

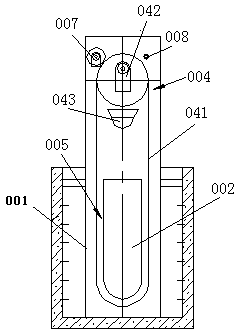

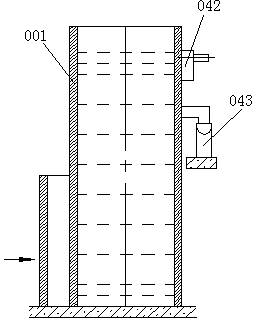

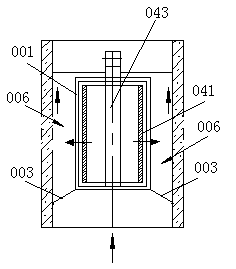

[0010] A kind of decontamination machine with internal inflow stepped screen grid, including a frame 001, the frame 001 is a rectangular box with unclosed left and right sides, the lower part of the frame 001 is immersed in the water inlet channel to be treated, A water inlet 002 is provided at the center of the facing surface of the lower part of the frame 001, and both sides of the water inlet 002 are provided with a water retaining plate 003 to prevent sewage from flowing into the frame 001 from both sides of the water inlet 002. The water retaining plate 003 One end is connected to the side wall of the water inlet 002, and the other end is connected to the side wall of the water inlet. The mesh plate sprocket mechanism 004 includes a mesh plate 041 and a sprocket 042 arranged on the top of the frame 001 to drive the mesh plate 041 in rotation. There is a slag discharge groove 043 under the sprocket 042, and the mesh plate 041 is a rotary filter mesh belt composed of thin st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com