Mold change assistance system for molding units of container manufacturing machines

A mold replacement and auxiliary system technology, applied in the field of mold replacement auxiliary systems, can solve problems such as shortening mold replacement time, and achieve the effects of eliminating direct manual intervention, improving working conditions, and eliminating manual operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

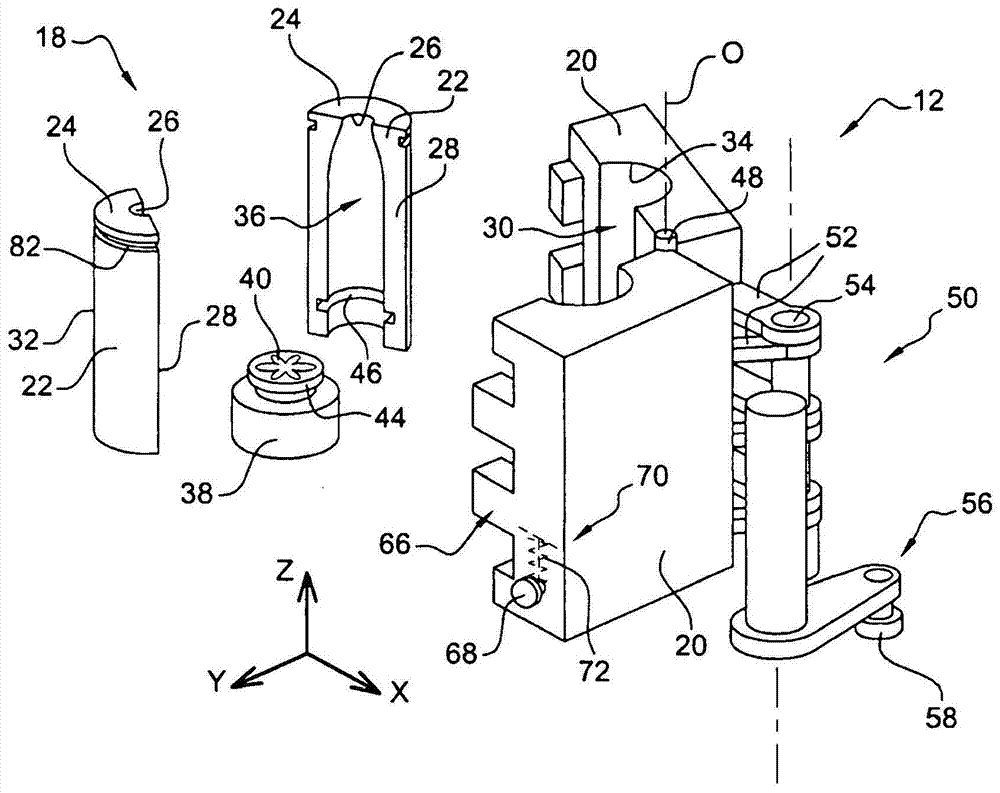

[0068] In the following description, the longitudinal orientation, the lateral orientation and the vertical orientation will be adopted without limitation with reference to the coordinate system (X, Y, Z) shown on the drawings.

[0069] According to custom, the longitudinal direction and the transverse direction are determined in a fixed manner relative to the mold base of the molding unit, and are not affected by the open or closed position of the molding unit.

[0070] Without limitation, the terms "front" and "rear" will be used with reference to the longitudinal direction, the terms "left" or "right" with reference to the lateral direction, and the terms "upper" or "lower" with reference to the vertical direction.

[0071] The present invention proposes a mold replacement auxiliary system 10 for the molding unit 12 of the container manufacturing machine 14.

[0072] Hereinafter, a preferred embodiment of the mold replacement auxiliary system 10, more particularly the conveying devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com