Column porcelain insulator

A porcelain insulator and column type technology, which is applied in the field of power communication equipment, can solve the problems of increased probability of steel-cored aluminum conductors being broken, steel-cored aluminum conductors falling, and endangering personnel safety, so as to reduce the failure rate of power outages and avoid endangering The effect of personnel safety and wear reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

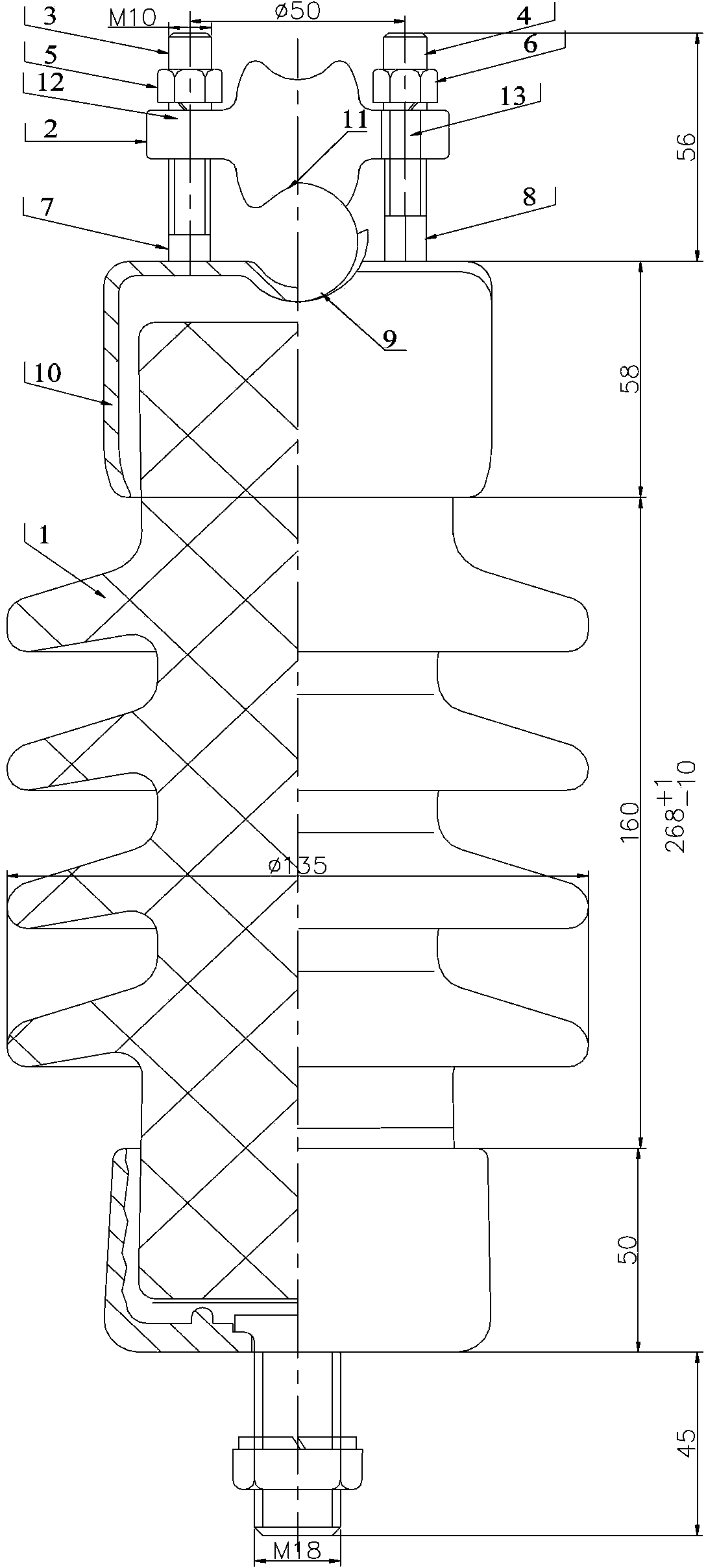

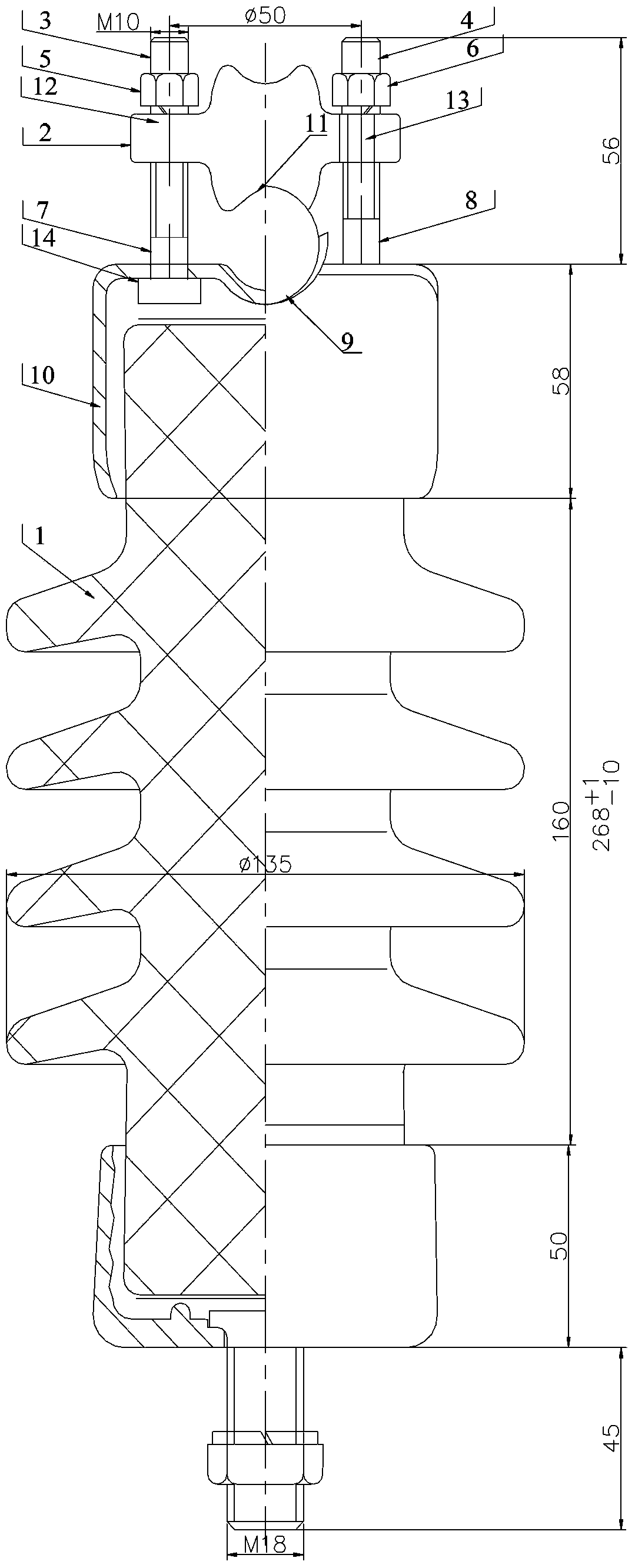

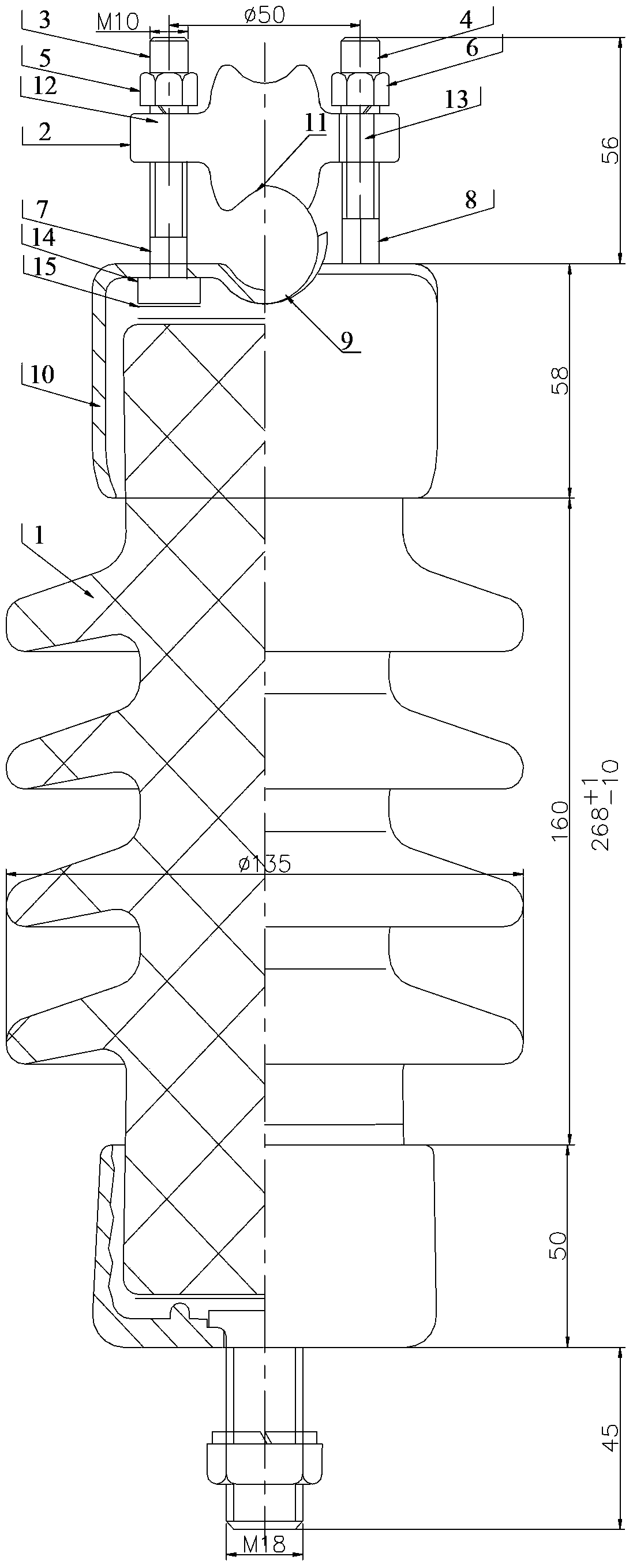

[0030] First, a post-type porcelain insulator provided in the embodiment of the present application will be described. The post-type porcelain insulator may include: a porcelain part, a wire pressing plate, a first bolt, a second bolt, a first nut matching the first bolt, and the second nut matched by the second bolt, the hollow first fixed rod and the hollow second fixed rod;

[0031] Wherein, one end of the porcelain part is provided with a first groove, and the end provided with the first groove is poured with an upper cap, and the upper cap does not cover the first groove;

[0032] The first fixing rod and the second fixing rod are fixed on the upper surface of the upper cap, and are respectively located on one side of the first groove;

[0033] The inner surface of the first fixing rod has threads matched with the first bolt, and the inner surface of the second fixing rod has threads matched with the second bolt;

[0034] A second groove identical to the first groove is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com