Non-cotton atomizer and electronic cigarette

A technology of atomizers and atomization components, which is applied in the direction of tobacco, tobacco pipes, smokers’ supplies, etc. It can solve problems that affect the consumption experience, e-liquid overflow, and unreliability, so as to improve the consumption experience, avoid the leakage of e-liquid, and prevent The effect of the oil spill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

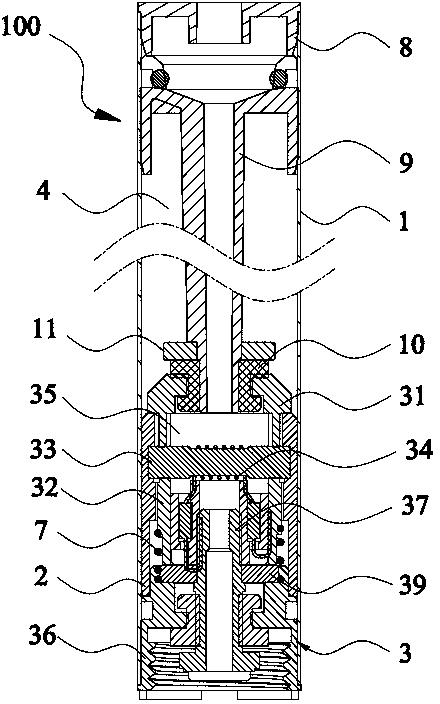

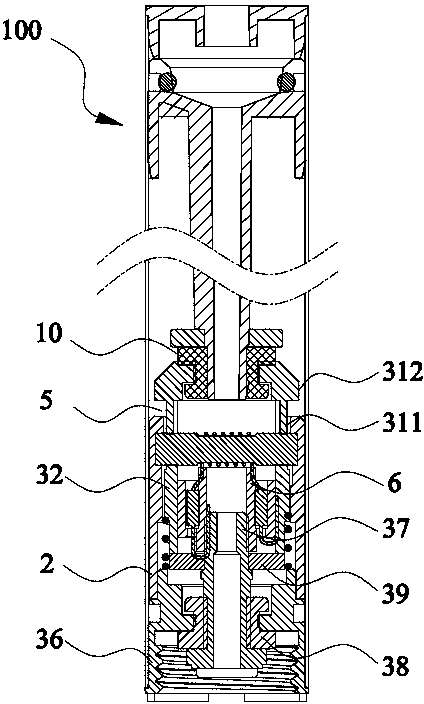

[0027] refer to Figure 1~Figure 3 As shown, this embodiment provides a cotton-free atomizer 100, which includes an atomization sleeve 1, an oil-repelling sleeve 2 fixed on the inner wall of the atomization sleeve 1, and an oil-repelling sleeve 2 that is arranged inside the oil-repelling sleeve 2 and can 2 An atomization assembly 3 that moves up and down along its axis. An oil storage cavity 4 is closed in the atomization sleeve 1 for storing smoke oil. The atomization assembly 3 obtains the e-liquid through the oil filling port 5 , and when the atomization assembly 3 moves up and down relative to the oil-blocking sleeve 2 , the oil injection port 5 can be opened or closed, thereby controlling the entry of the e-liquid into the atomization assembly 3 . The oil injection port 5 communicates with the oil storage chamber 4. When the oil injection port 5 is opened, the smoke oil can directly enter the atomization assembly 3 and be heated to form smoke, which can be inhaled...

Embodiment 2

[0039] refer to Figure 7 As shown, this embodiment provides an electronic cigarette 300, which includes a battery rod 200 and the cotton-free atomizer 100 described in Embodiment 1. The battery rod 200 includes a battery case 201 and a battery assembly located in the battery case 201 202 and a central pin 203 arranged at the end of the battery case 201 and electrically connected to the battery assembly 202 . One end of the battery cover 201 is provided with a screw thread 204 that can be screwed and connected with the cotton-free atomizer 100. When the battery cover 201 and the cotton-free atomizer 100 are screwed together, the center needle 203 just pushes the cotton-free atomizer 100. The tail end of the electrode ring 37 enables the electrode ring 37 to drive the atomization assembly 3 to move axially relative to the oil resistance sleeve 2, thereby opening the oil filling port 5, and the e-liquid is injected into the glass fiber core 33, so that the electronic ciga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com