Electric cover plate

A technology of power cover and cover, which is applied in substations, industrial buildings and other directions, can solve the problems of power equipment safety impact, theft, and cement-made bulky, etc., and achieves the effect of good bite and protection of power equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

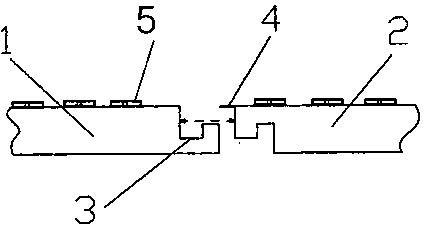

[0010] The power cover is usually spliced together in two pieces. The middle plane of the cover is high, while the splicing edge is low. The cover plate 1 is in the shape of a depression, while the upper cover plate 2 on the top is in the shape of a buckle, and a shielding plate 4 is provided at the splicing gap.

[0011] The power cover is made of unsaturated polyester resin.

[0012] There is a water separation groove 3 on one side of the concave shape, and the water separation groove 3 is also high in the middle and low on both sides, so that the rainwater flowing in from the middle of the two electric cover plates can flow into the drainage ditch on both sides in the water separation groove, thereby avoiding rainwater Inflow damages electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com