Disassembly and assembly device of valve assembly

A technology for installing devices and valves, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of high labor intensity of operators, low assembling success rate, and difficulty in locking blocks, and achieves low labor intensity, light use and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. However, the examples given are not intended to limit the present invention.

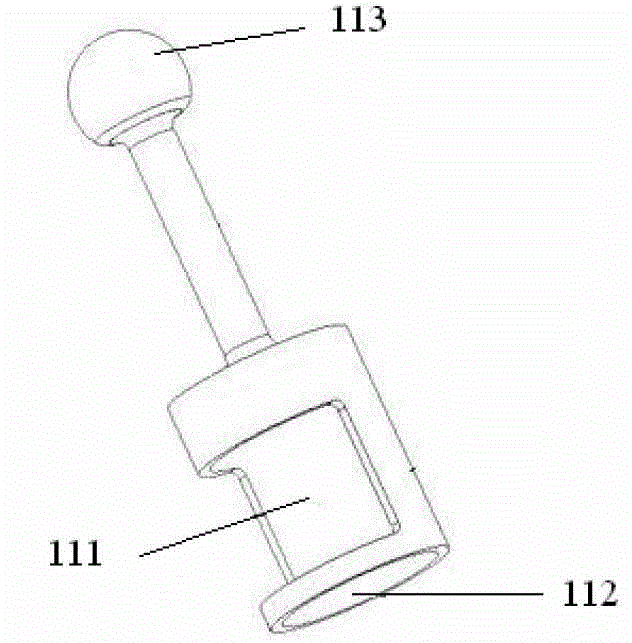

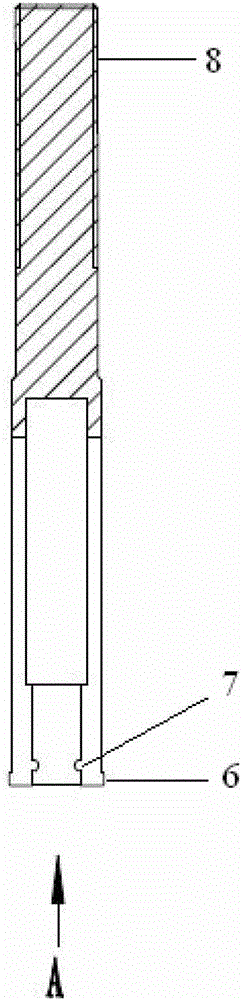

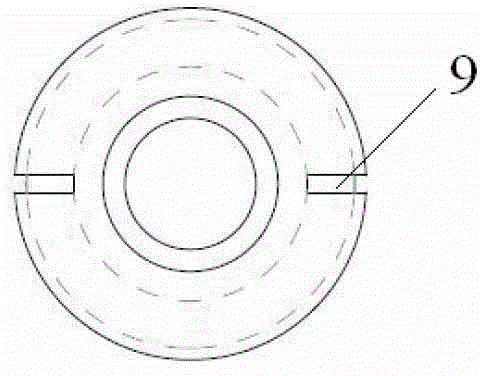

[0022] see Figure 5 , the embodiment of the present invention includes a bracket 1, a pull rod 2, a safety ring 3 and an adjustment nut 4, the pull rod is a cylindrical structure, and the figure 2 , the lower part of which is a hollow inner cavity, the bottom edge of the pull rod is provided with an outer edge 6, the safety ring is sleeved on the bottom end of the pull rod, and is stuck on the outer edge, and the bottom of the inner cavity is provided with a boss 7 and a notch 12 of the valve Matching, the lower part of the pull rod has a flaring groove 9 along the axial direction; the bracket is a cylindrical sleeve, the upper end of the bracket is provided with a through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com