A linear positioner using a synchronous belt

A synchronous belt and positioner technology, which is applied to large fixed members, metal processing machinery parts, manipulators, etc., can solve the problems of increasing the wear of the transmission gearbox and reducing the service life, so as to improve the rigidity and precision, reduce the maintenance cost, and shorten the pulling time. The effect of extension length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

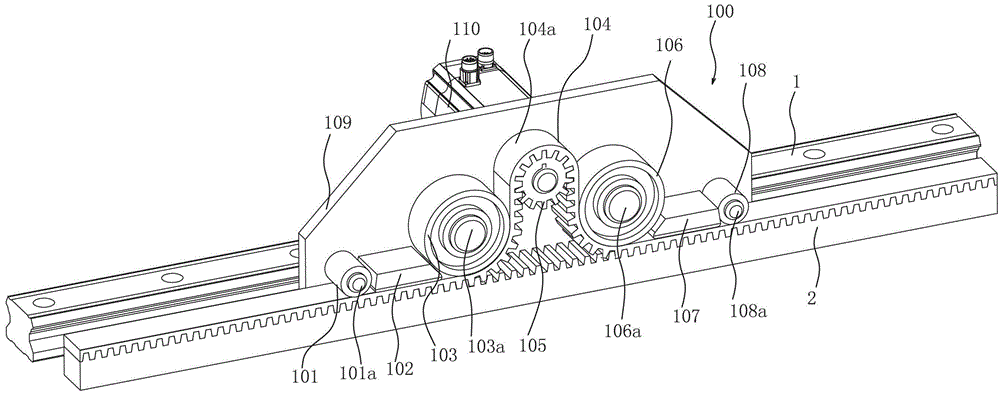

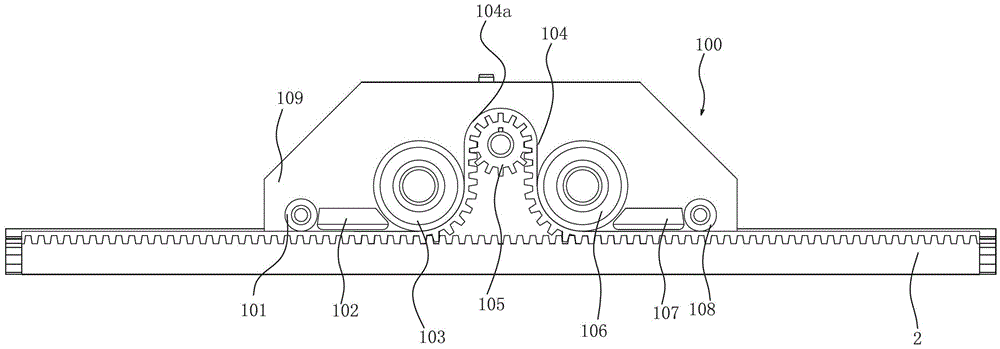

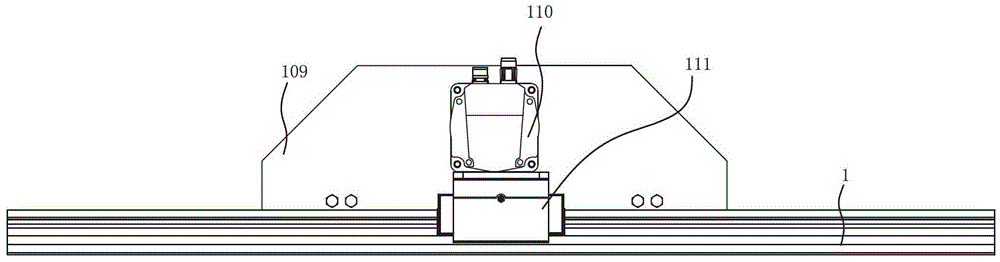

[0022] figure 1 is a three-dimensional structure diagram of a linear positioner according to an embodiment of the present invention. like figure 1 As shown, the linear positioner mainly includes a base (not shown in the figure) and a moving platform 100, and a guide rail 1 and a base timing belt 2 (or a base rack 2) are provided on the base. Each moving platform 100 is provided with a bracket 109 , one side of the bracket 109 is provided with a belt gear 105 , and the other side is provided with a motor 110 . The output shaft of the motor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com