Data processing method for prediction of multilevel threshold force caused by composite impact

A technology of layered threshold and composite materials, which is applied in the direction of testing the strength of materials using a single impact force, can solve the problems of low prediction accuracy, and achieve the effect of solving the problem of low accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] There is a composite laminate material, the equivalent elastic modulus E of this material system is 1.77×10 11 Pa, equivalent Poisson's ratio μ=0.34.

[0028] The reference test piece number is T0, thickness h 0 =0.00846m, its response can be regarded as the impact response of the half-space plate when it is impacted.

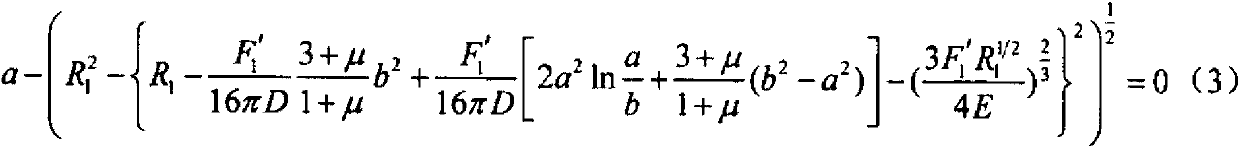

[0029] The test piece to calculate the impact delamination threshold force is T1, the equivalent radius of T1 is b=0.09m, and the thickness is h 1 =0.003m, equivalent bending stiffness D=161N·m. its radius R 1 = Delamination threshold force F under the action of 0.008m impact head 1 The calculation process of is as follows.

[0030] Use a radius of R 0 = 0.0127m impact on T0, the delamination threshold force is 18932N.

[0031] Using the formula (1), the delamination strength S of this material is calculated as 3.54×10 8 Pa.

[0032] An approximate value F of the layered threshold force at T1 was calculated using formula (2) 1 '=3173N.

[0033...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com