A magnetic wire tooling

A technology of electric wires and tooling, which is applied in the field of electrical accessories connection devices, and can solve problems such as inconvenient disassembly and assembly, and easy slipping of power supply terminals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

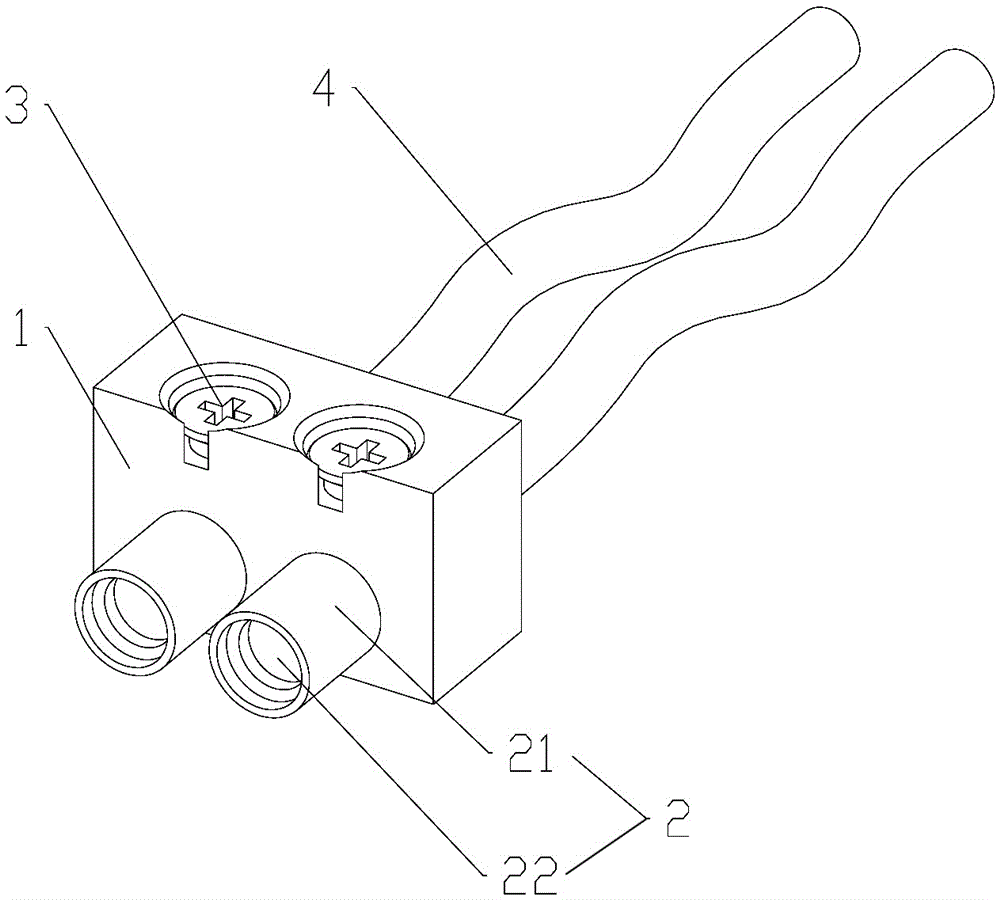

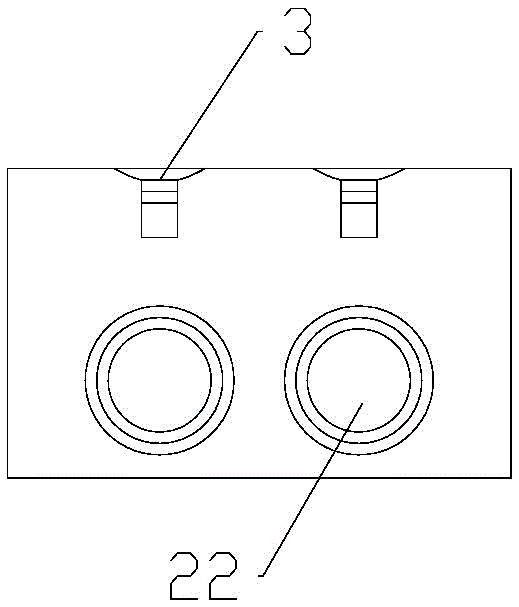

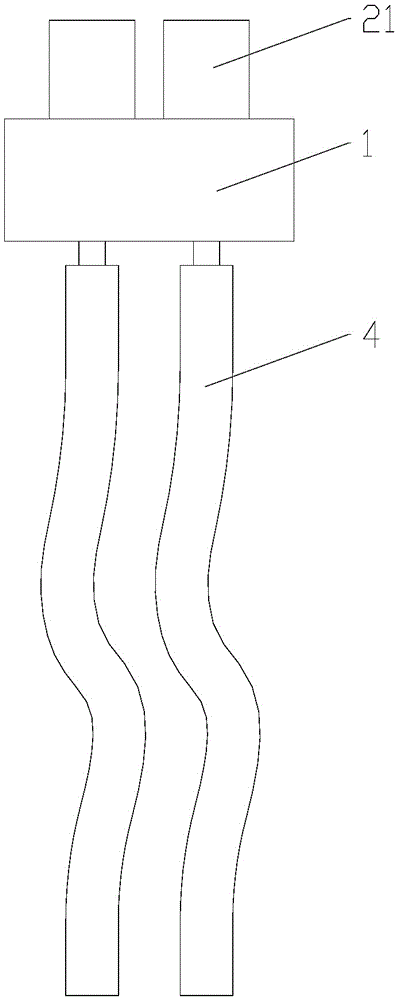

[0019] Such as Figure 1 to Figure 6 As shown in any one, a magnetic wire tooling is composed of an insulating base body 1, a metal conductive connector 2, a wire fixing screw 3 and a wire 4; the metal conductive connector 2 is composed of a conductive metal shell 21 and a cylindrical magnet 22 The cylindrical magnet 22 is embedded in the conductive metal shell 21, and the conductive metal shell 21 is inserted in the insulating seat body 1; the upper surface of the metal conductive connector 2 has an incoming wire hole 23, and the wire 4 is inserted into the incoming wire In the hole 23 ; the side of the metal conductive connector 2 has a screw hole 24 , and the screw hole 24 cooperates with the wire fixing screw 3 to fix the wire 4 inserted into the wire inlet hole 23 .

[0020] The two wires 4 are respectively inserted into the two corresponding wire inlet holes 23 , and then fastened with the wire fixing screws 3 in the side screw holes 24 of the metal conductive connector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com