Pipe machine

A technology of pipe arranging machine and conduit, which is applied to detonators, attack equipment, etc., can solve the problems of difficult automatic sorting of pipe shells and complicated automatic sorting devices, etc., and achieve the effect of improving pipe arranging efficiency and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the concrete embodiment of pipe arrangement machine of the present invention is described in detail.

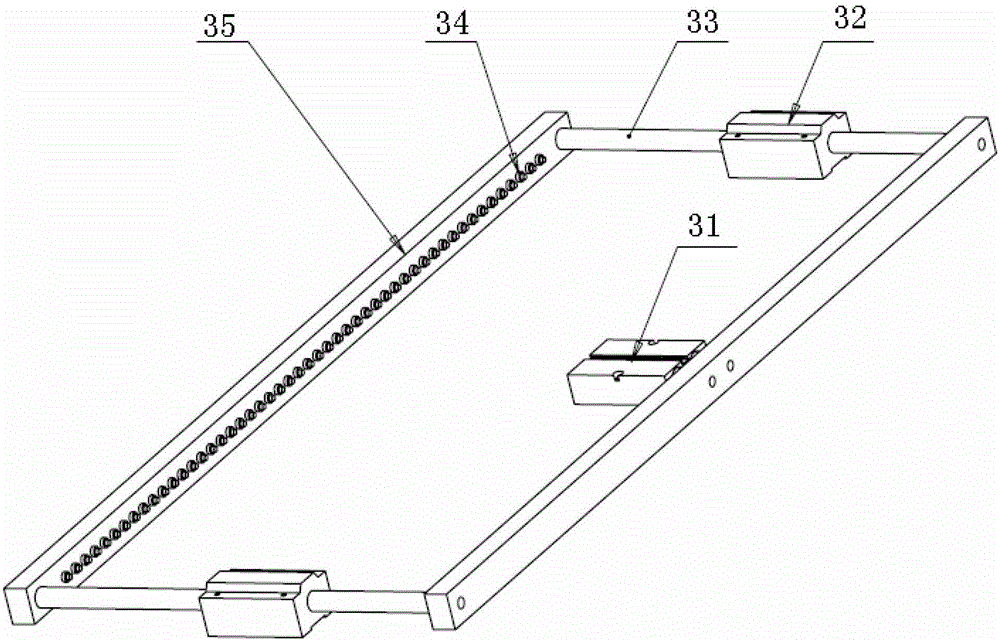

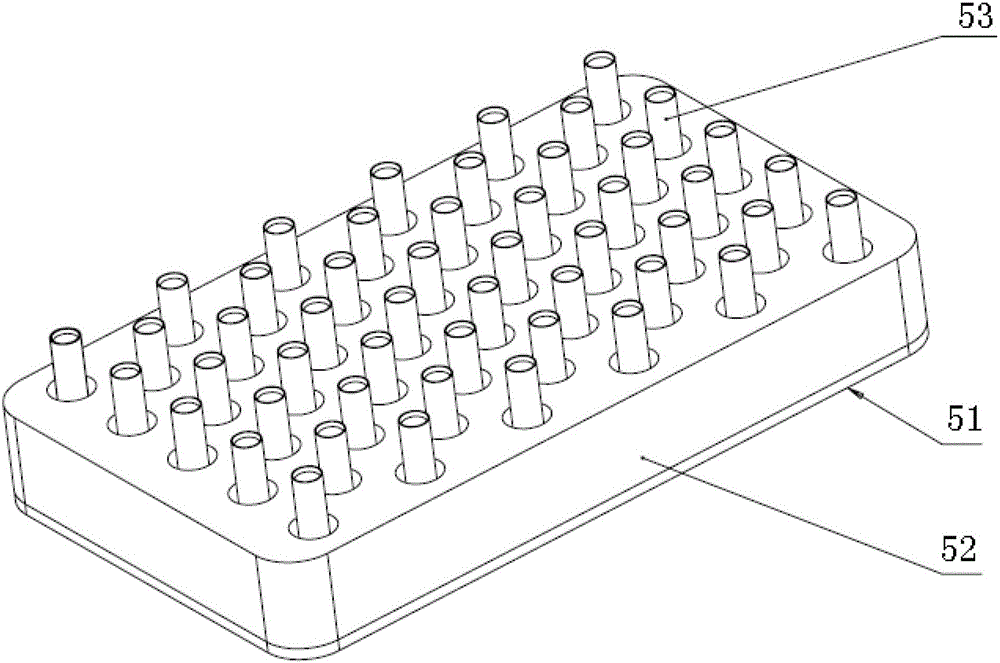

[0024] First refer to figure 1 , figure 1 It is an assembly schematic diagram of the pipe arrangement machine of the present invention. It includes a storage smoothing mechanism 1, a locking head 2, a turning mechanism 3, a feeding conduit 4, a conduit mold 5, a push-in cylinder 6, a push-out cylinder 7 and a frame 8.

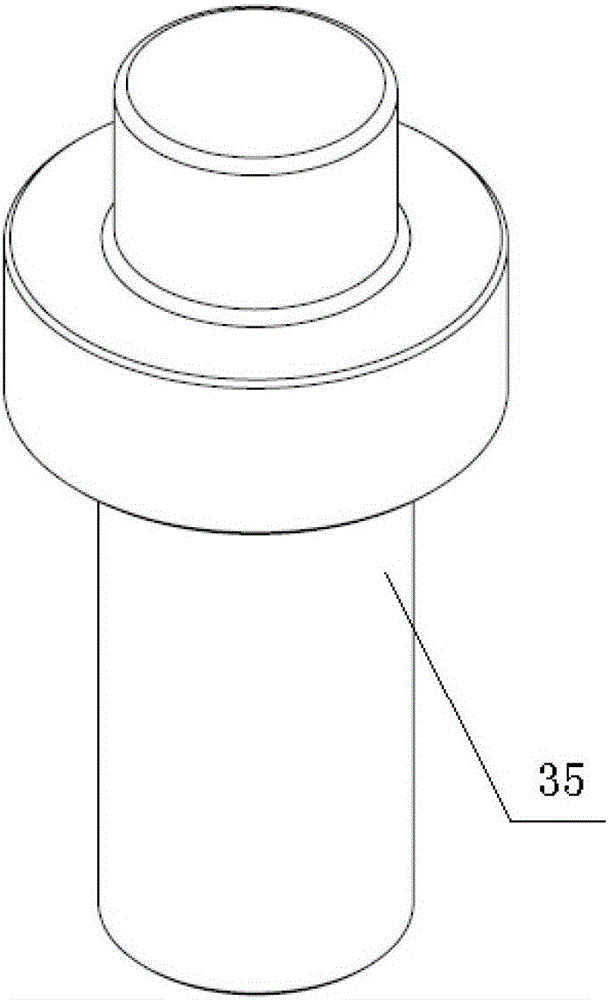

[0025] The above-mentioned mechanisms are all arranged on the frame 8, wherein the storage and arrangement mechanism 1 is fixed on the uppermost part of the frame, and the detonator shell 53 that has been straightened out by the storage and arrangement mechanism 1 enters and is arranged on the frame through a row of inclined slideways. In a row of locking heads 2, the function of the locking head 2 is to lock the casing 53, and send it to the feeding conduit 4 through the U-turn mechanism 3, wherein the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com