Maize harvester capable of bundling stalks continuously

A technology of corn harvester and baler, which is applied in the direction of baler, harvester, agricultural machinery and implements, etc., and can solve the problems of falling materials and loose bales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

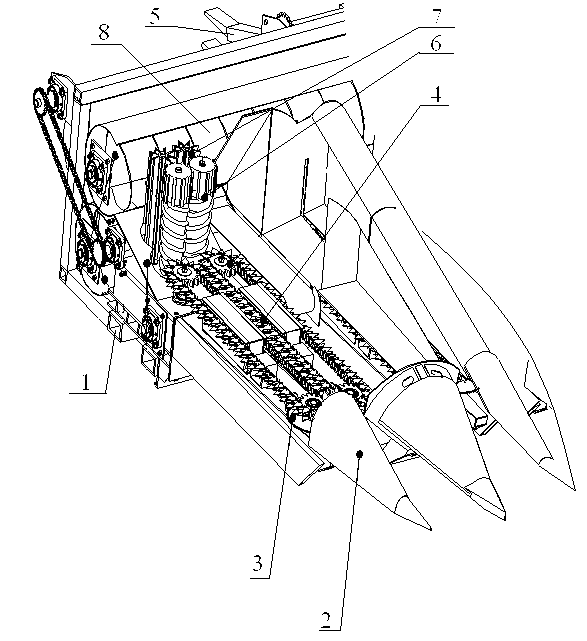

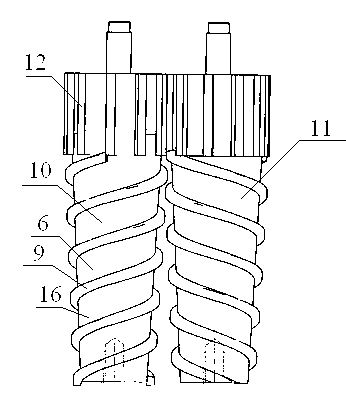

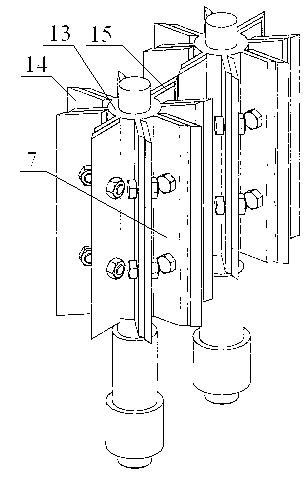

[0014] The present invention consists of a car body 1, a grain reel 2, a cutting saw 3, a clamping chain 4 and a baler 5, and a pull stem is installed on the car body 1 between the tail end of the clamping chain 4 and the baler 5 Squeeze roller group 6 and segment cutter roller group 7, pull stem extrusion roller group 6 to be made of two columnar bodies 16 perpendicular to the chassis of car body 1, there is spiral groove 9 on the columnar body 16, columnar body 16 passes bearing and Car body 1 is connected, and is connected with the drive motor that makes it rotate, and two columnar bodies 16 are horizontally placed side by side, and there is a gap between them, and segment cutter roller group 7 is made up of two roller columns 13 perpendicular to the chassis of car body 1, Seven blades 14 are arranged on each roller 13, and blade 14 is axially fixed on the roller 13, and it is radial in plan view, and roller 13 is connected with car body 1 by bearing, and is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com