Combined sealing device for plunger pump

A combined sealing and plunger pump technology, which is applied to components, pumps, pump components, etc. of pumping devices for elastic fluids, can solve the problem that the working performance and sealing performance are difficult to meet the working needs, and reduce the actual sealing effect of packing seal rings , the actual service life impact and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

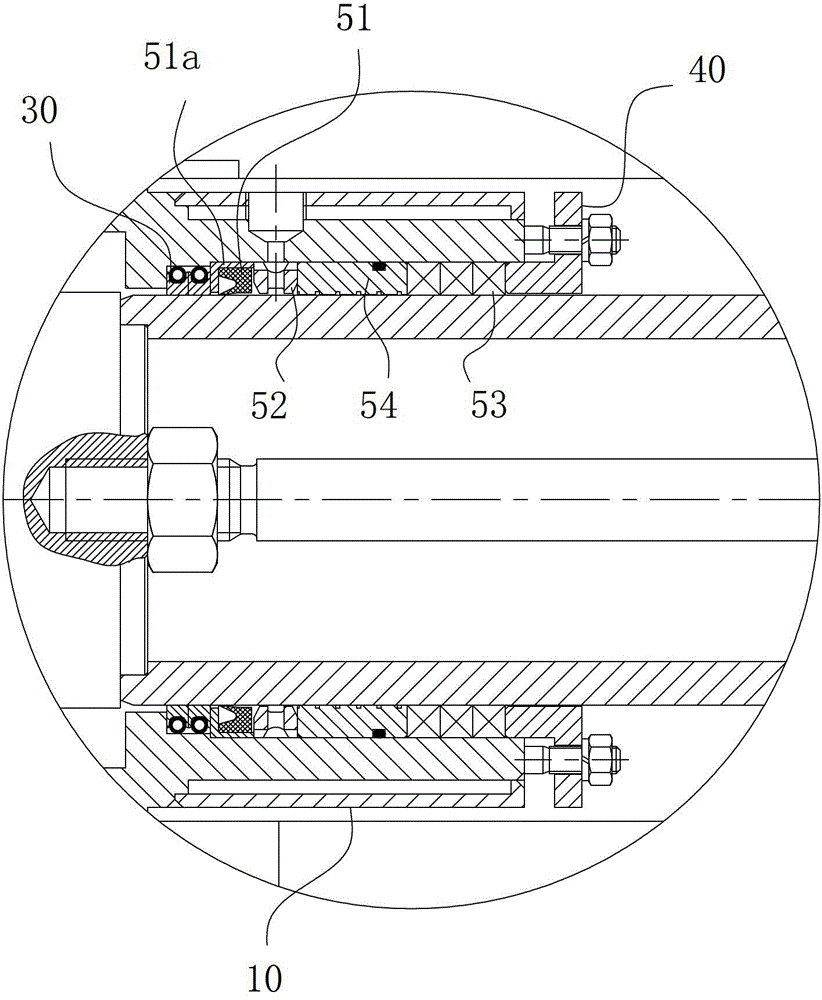

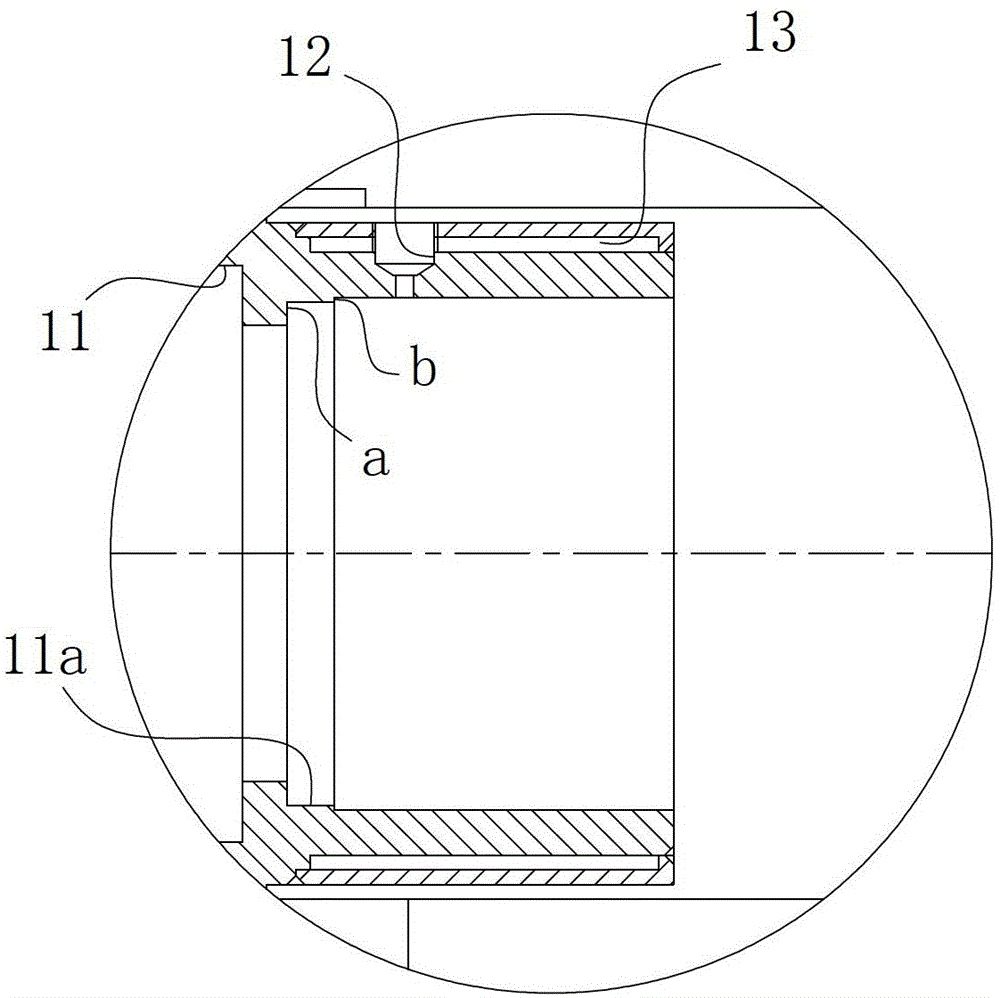

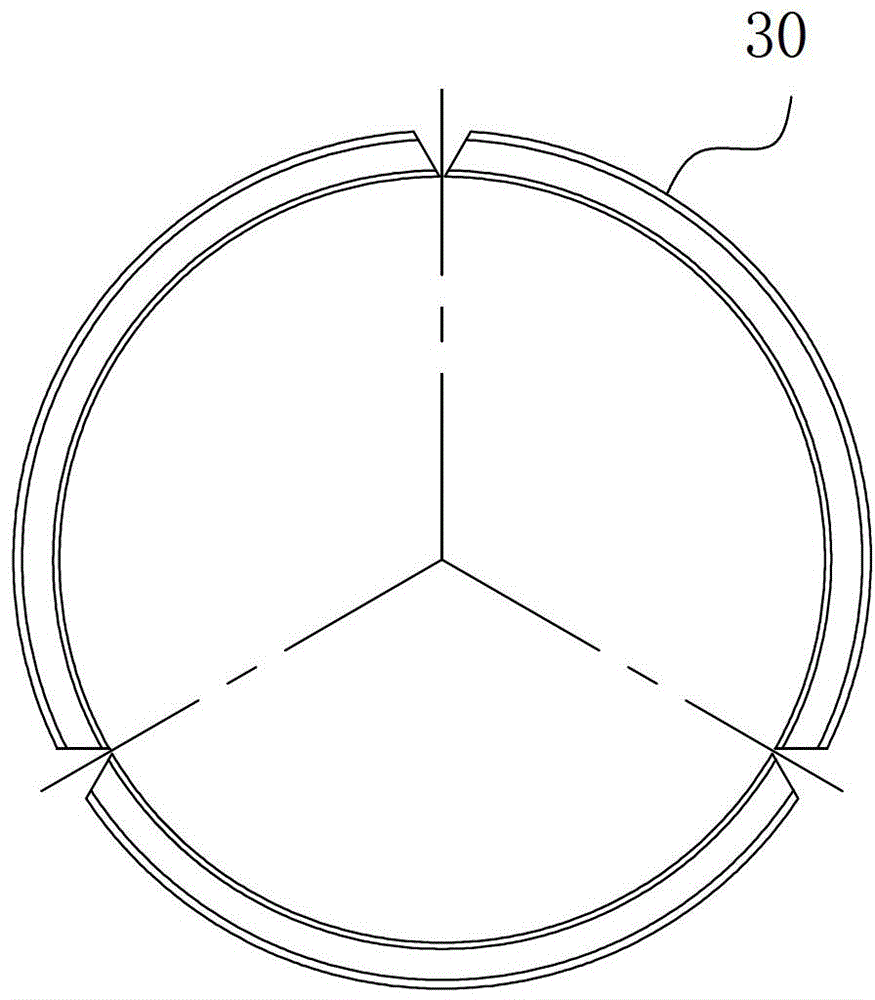

[0027] For ease of understanding, combined here Figure 1-5 Concrete structure of the present invention and assembly process are described as follows:

[0028] see Figure 1-5 As shown, the combined sealing assembly of the present invention is composed of the combined slag guide scraper ring (that is, the petal ring parts constituting the scraper ring 30 ) and the elastic pressing part 32, the seal ring 51 and the cage 51a. The secondary seal structure, liquid seal ring 52, labyrinth seal ring 54 and packing seal ring 53 are combined, and finally the entire combined seal is fixed on the pump cylinder 10 by pressing the end cover 40, so as to realize the whole The sealing purpose of the gap between the plunger part 20 and the plunger hole 11 on the plunger pump. The characteristics of the present invention are: on the one hand, through the close cooperation between the combined slag guide valve ring and the surface to be scraped, relying on the rigid scraping effect of the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com