Switching arrangement in gas-insulated or vacuum-insulated switchgear assemblies

A power distribution device, vacuum insulation technology, applied in the direction of circuits, electric switches, electrical components, etc., can solve the problem of high complexity of maintenance and achieve a good cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

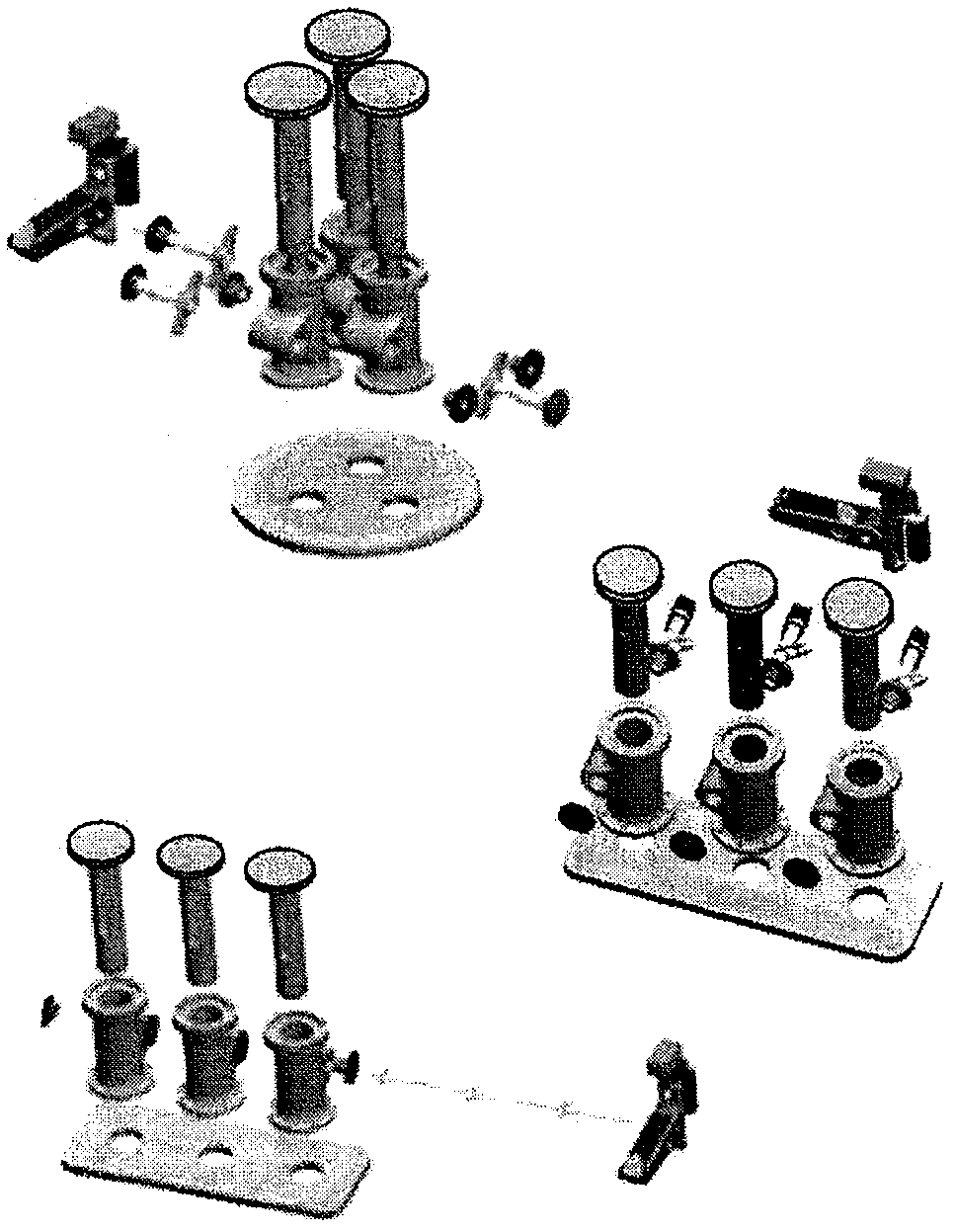

[0071] figure 1 A power distribution device built from standard modules is shown, which meets different requirements. Three such distribution units are in figure 1 shown in . Power distribution units built from standard modules are available in Figures 2 to 5 shown in detail.

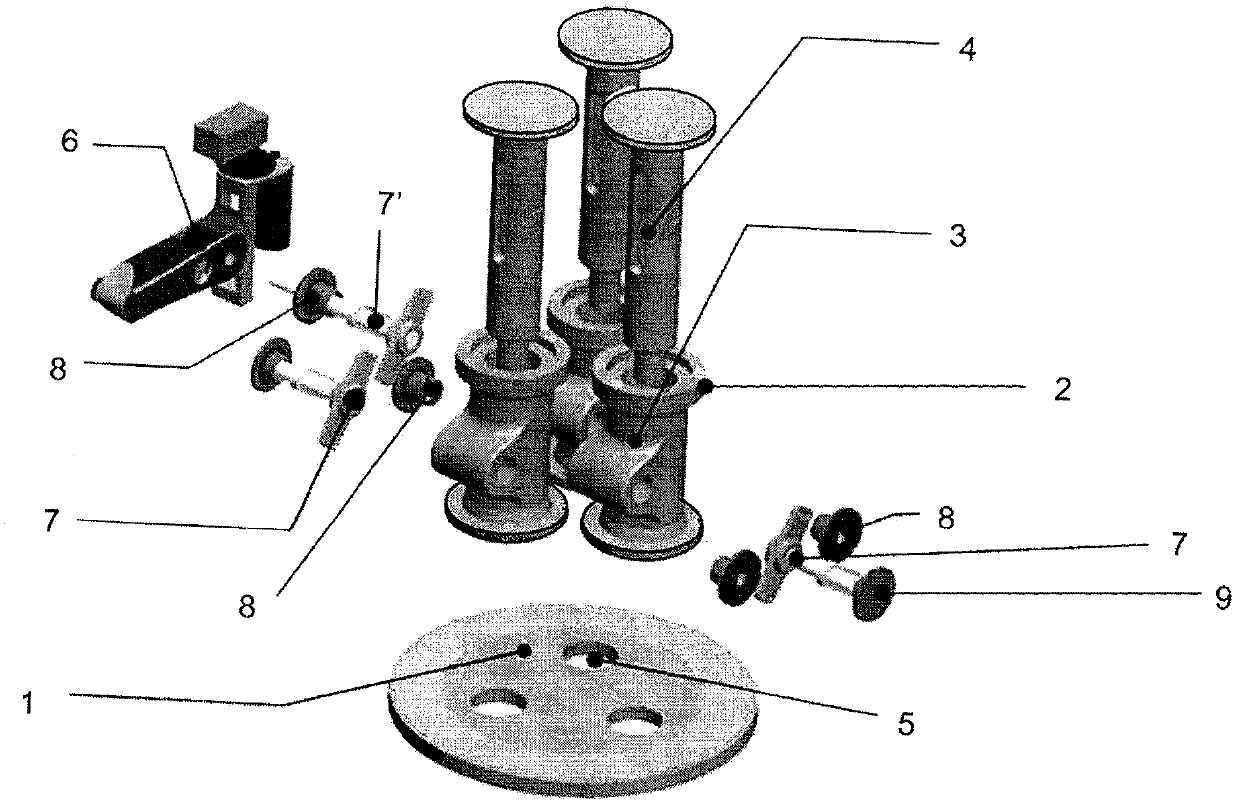

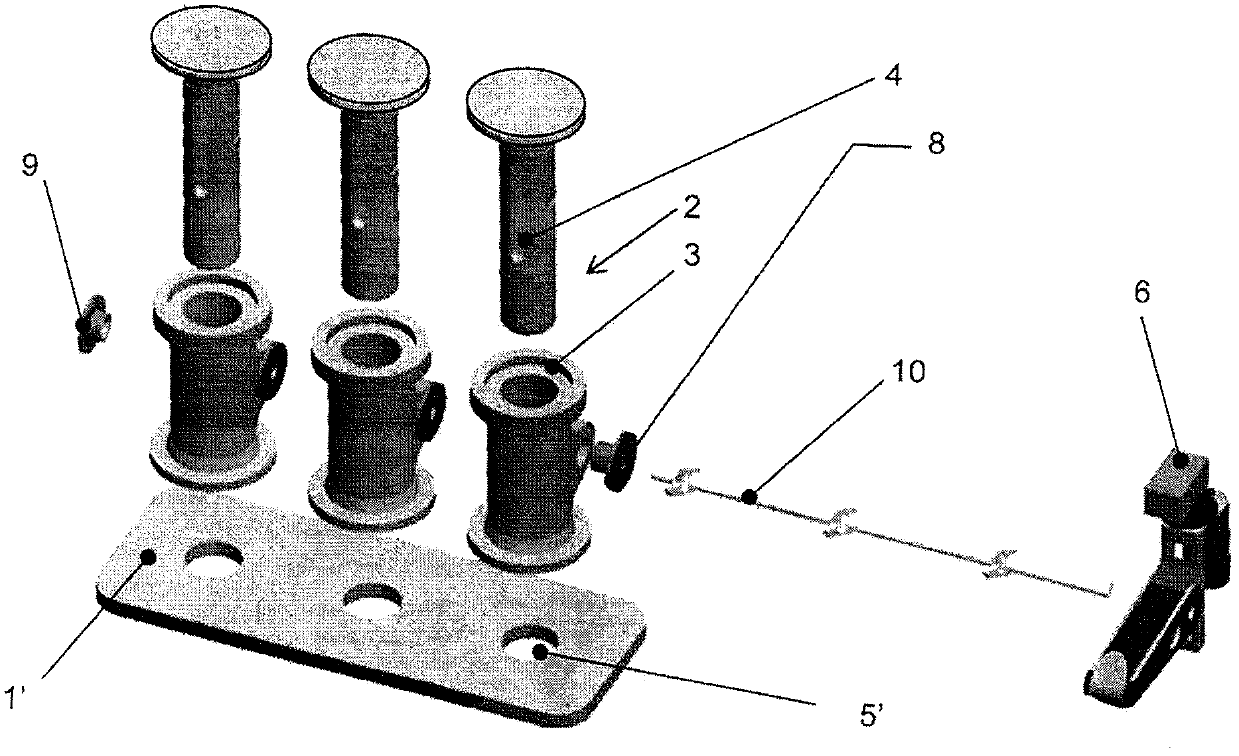

[0072] figure 2 A base carrier module 1 is shown for receiving a single-contact module 2 . The single-contact module 2 consists of a housing 3 and a moving contact carrier 4 . The base carrier module 1 has a circular hollow 5 whose midpoints form an equilateral triangle.

[0073] in addition, figure 2 A bistable electromechanical drive module 6 is shown, which can be connected to the single-contact module 2 via one actuator connection assembly 7' and two further connection assemblies 7. In addition, a dynamic sealing module 8 and a static sealing module 9 are arranged on the connecting components 7, 7'.

[0074] figure 2 A power distribution device is shown, comprising a drive module 6 , w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com