Automatic IC (integrated circuit) burning method

A burning method and automatic technology, applied in information storage, static memory, instruments, etc., can solve the problems of low production efficiency, manpower and material resources consumption, and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

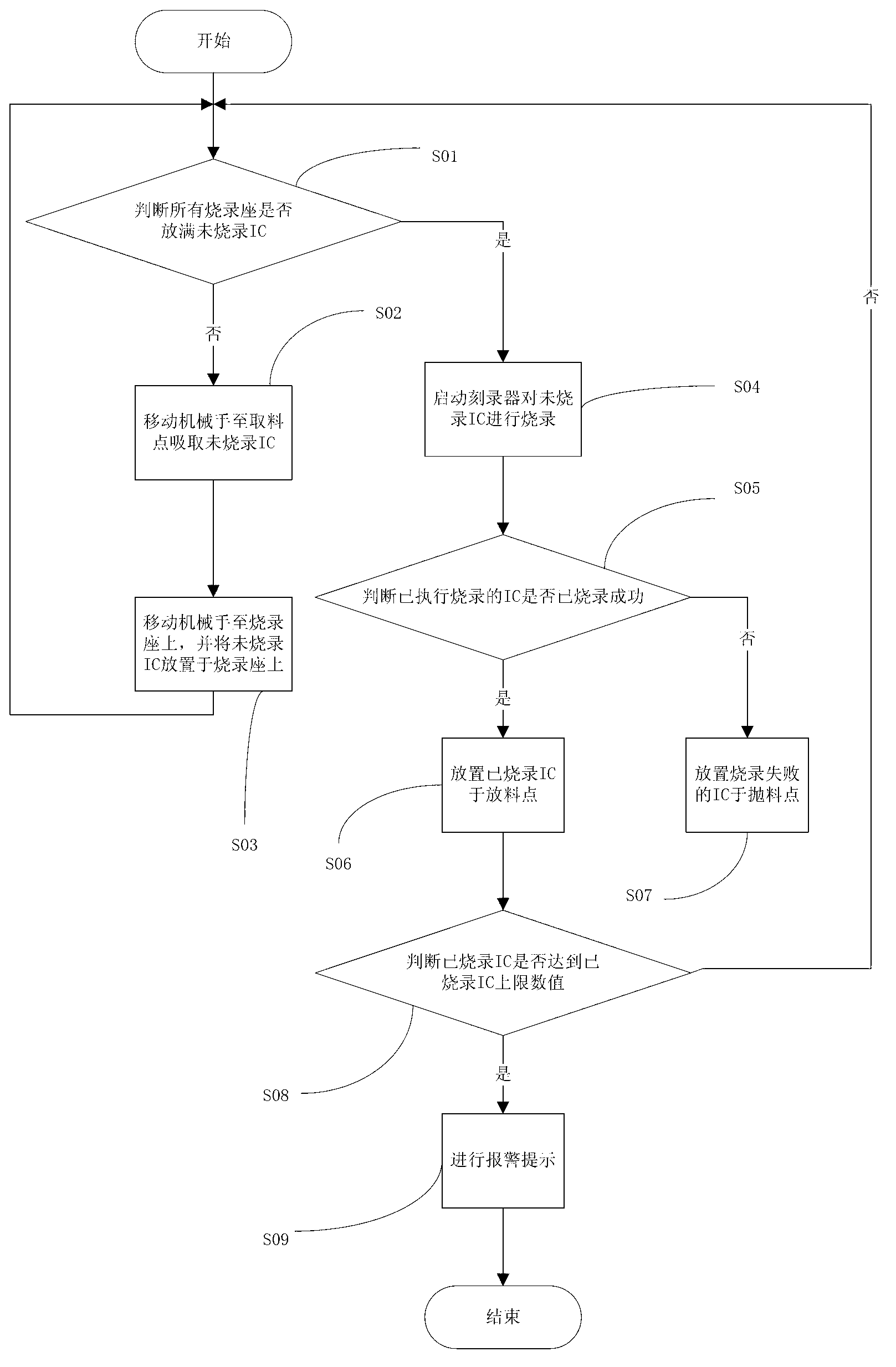

[0036] See figure 1 , the present invention relates to a kind of IC automatic programming method, and its preferred embodiment comprises the following steps:

[0037] Step S01: Determine whether all programming sockets are full of unprogrammed ICs, if not, execute step S02; if yes, execute step S04.

[0038] Step S02: Move the manipulator to the pick-up point to pick up unprogrammed ICs according to the preset pick-up point coordinates. This step includes the following sub-steps:

[0039] Step S021: Move the X-axis assembly and the Y-axis assembly in the horizontal direction according to the preset X-coordinate value and Y-coordinate value of the material picking point. Wherein, the X-axis assembly and the Y-axis assembly are driven by motors.

[0040] Step S022: Move the P-axis mechanism and the Z-axis mechanism downward according to the preset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com