Traverse lifting transfer trolley

A trolley and jacking technology, applied in the direction of lifting devices, etc., can solve the problems of large volume of two heavy equipment, high equipment purchase cost, and high work site requirements, and achieves travel speed improvement, purchase cost savings, and strong mobility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

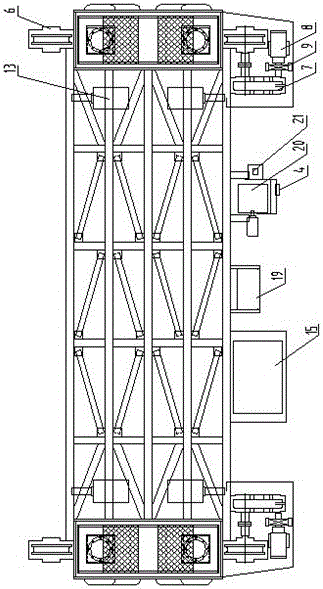

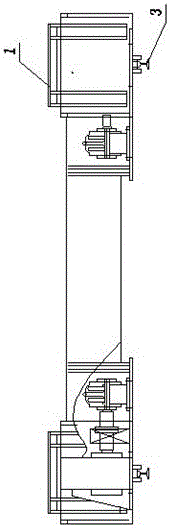

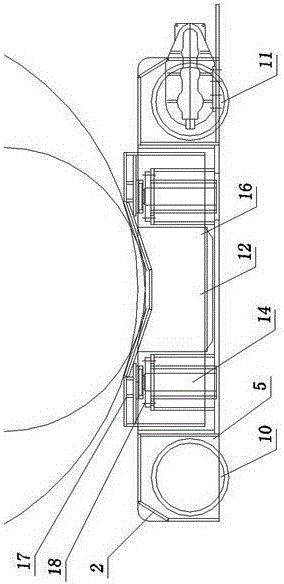

[0039] The laterally moving jacking transfer trolley of this embodiment includes a jacking mechanism 1, a traveling mechanism 2, and a traveling guide rail 3 from top to bottom, and also includes a remote control conversion control system that controls the traveling mechanism 2 And jacking mechanism 1, walking guide rail 3 comprises two tracks that are positioned at the left and right ends of trolley, and corresponding jacking mechanism 1 and running mechanism 2 are equally divided into two parts, are positioned at the left and right ends of trolley respectively.

[0040] The traveling mechanism 2 includes an active traveling mechanism and a driven traveling mechanism. The driven traveling mechanism includes a driven traveling wheel train located at the rear of the trolley, and the active traveling mechanism includes a traveling frame structure 5 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com