1/3 coking coal quality evaluation method

An evaluation method, coking coal technology, applied in the direction of material inspection products, fuel oil testing, etc., can solve the problems of large evaluation differences, unclear weights, and inability to accurately match, and achieve the effect of reducing thermal performance fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail through specific embodiments below.

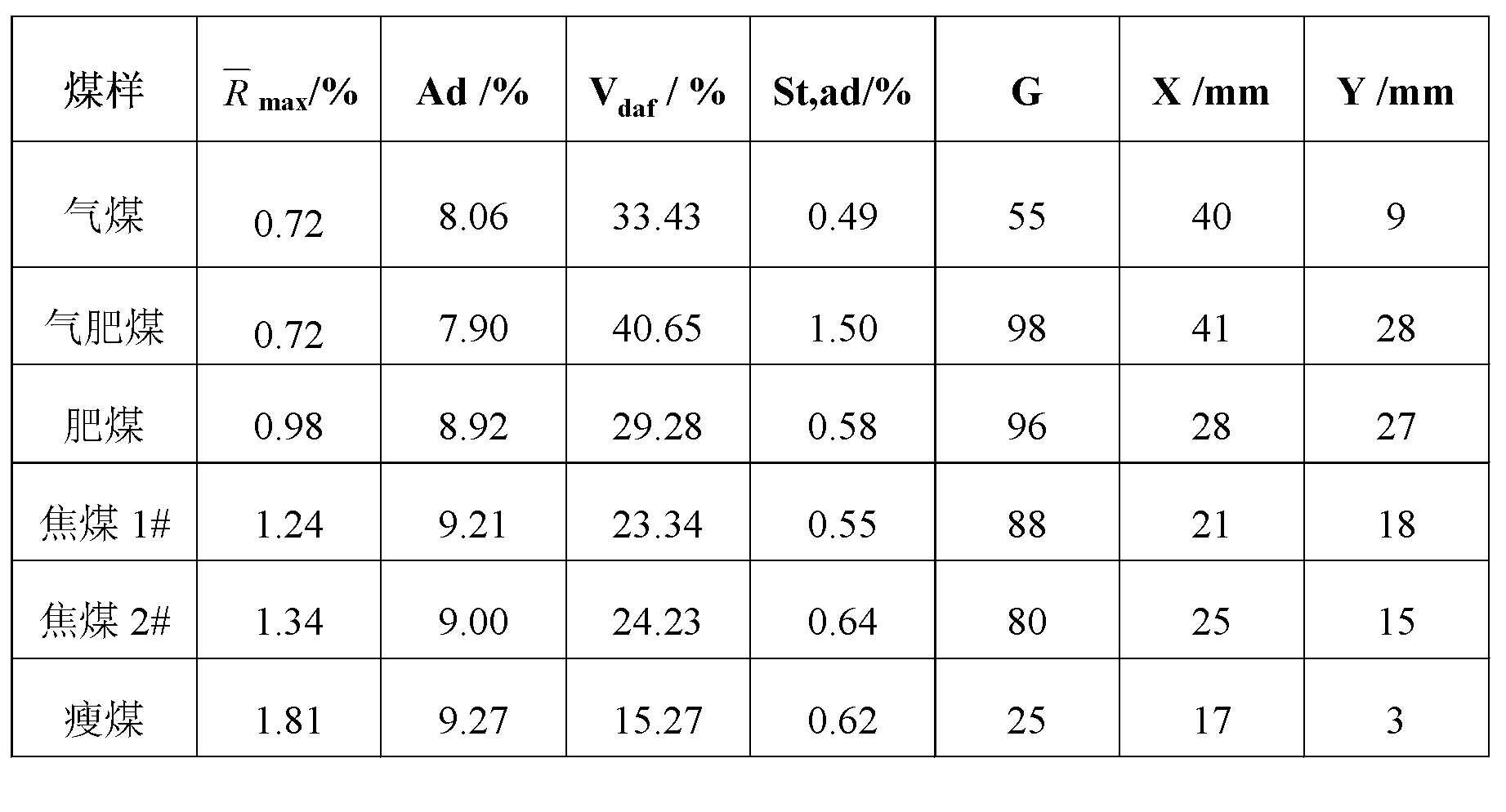

[0018] The proportion of 1 / 3 coking coal of an enterprise is 30%, and its coal blending plan is as follows:

[0019] Gas fat coal: 5%; 1 / 3 coking coal: 30%; fat coal: 10%; coking coal 1#: 20%; coking coal 2#: 20%; lean coal: 15%. The G value of the coking coal 1# is ≥85, and the proportion of coke-forming coarse-grain mosaic structure is ≥60%, and the G value of the coking coal 2# is 80-85, and the proportion of coke-forming coarse-grain mosaic structure is 50-60%.

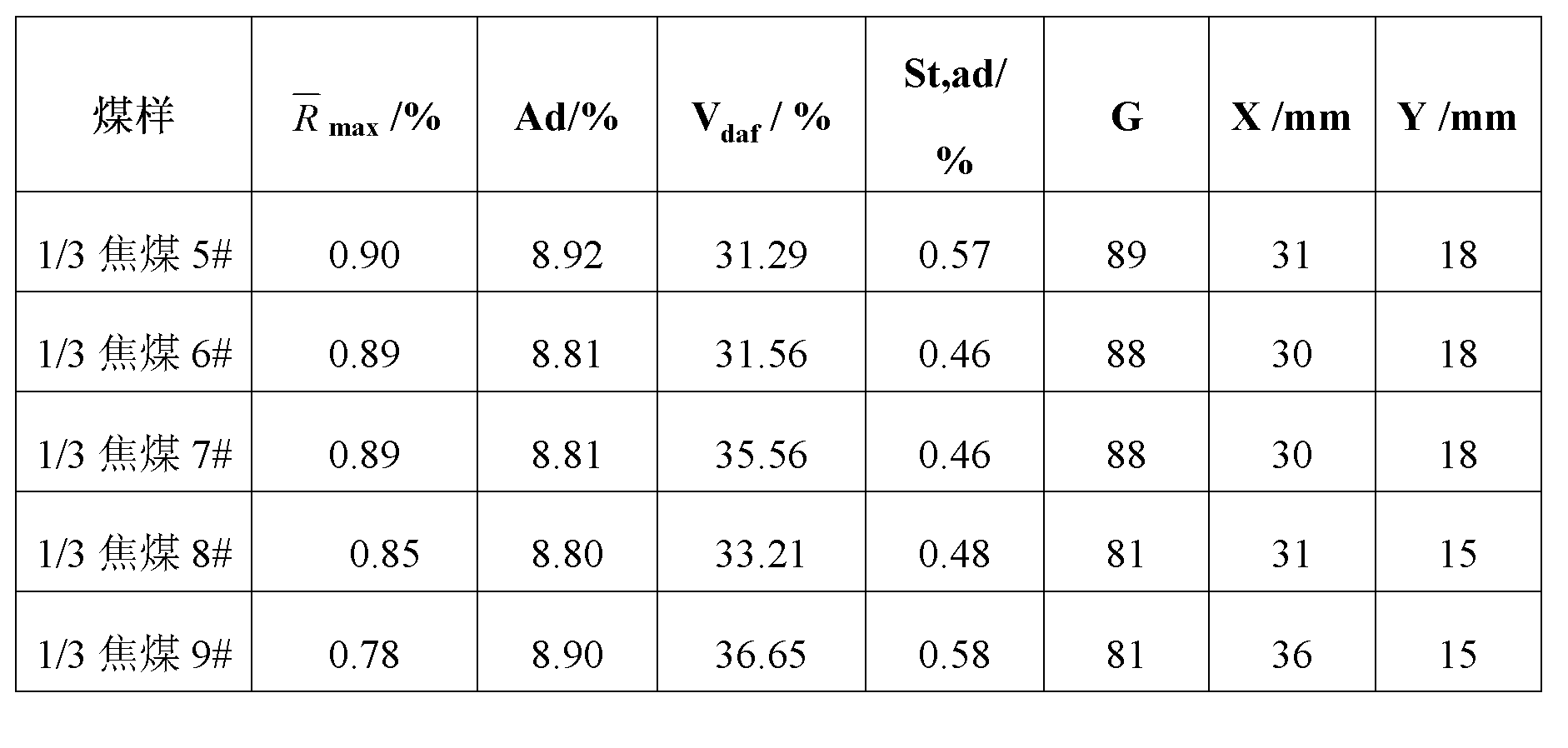

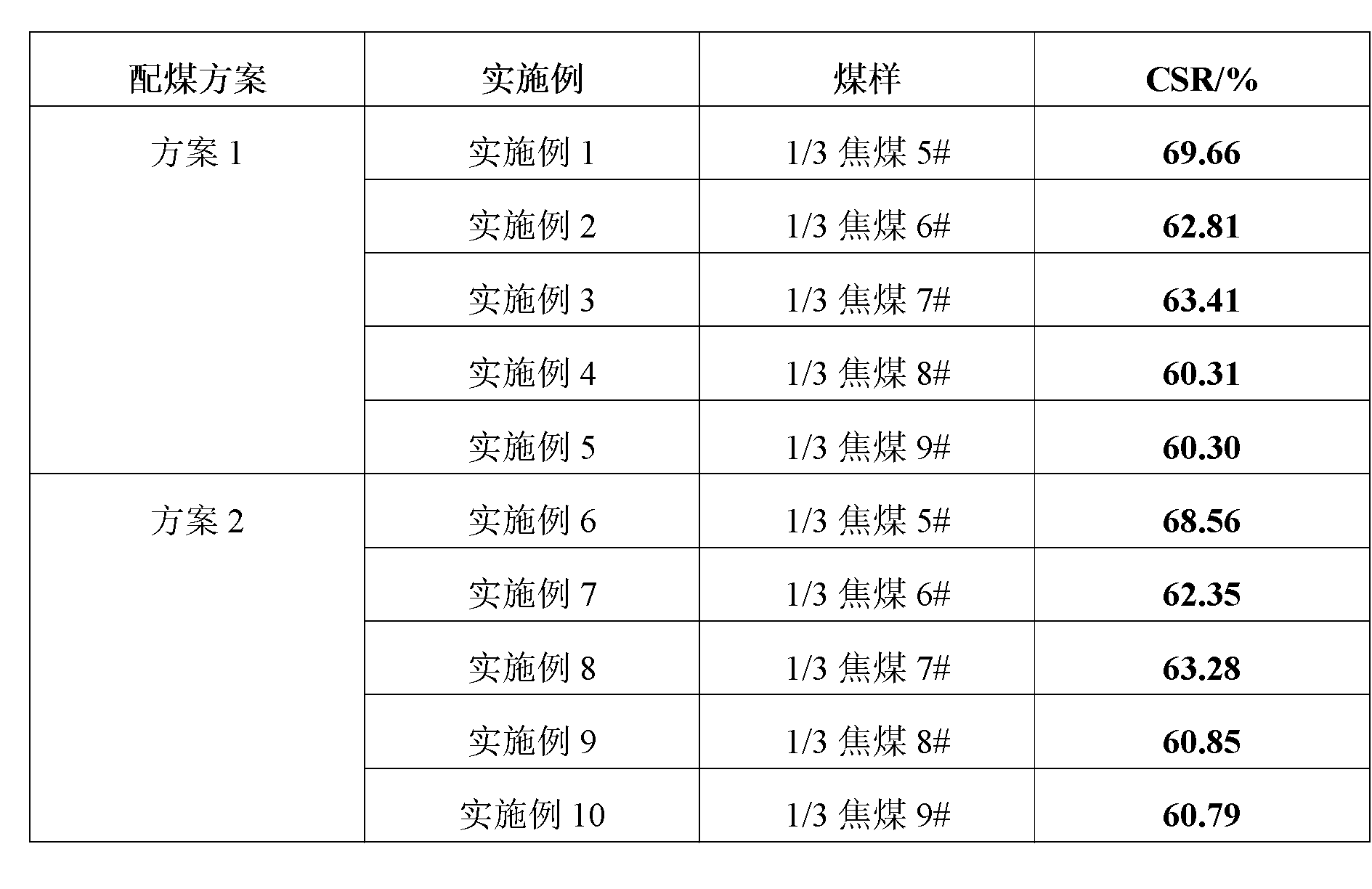

[0020] Gas fat coal, fat coal, coking coal 1#, coking coal 2#, and lean coal remain unchanged, and four groups of different 1 / 3 coking coals are used to carry out coal blending and coking according to the above-mentioned ratios to obtain the strength of coke after thermal reaction. See Table 1 for the data.

[0021] Table 1 The strength of coke after thermal reaction after coal blending with different 1 / 3 cokin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com