Ultra-intense femtosecond laser pulse full-parameter in-situ measurement system, measurement method and application

A femtosecond laser and laser pulse technology, applied in instruments and other directions, can solve the problems of large error, poor physical correlation and real-time performance, small sensitivity and dynamic range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In the following, the present invention will be further explained through specific embodiments in conjunction with the drawings.

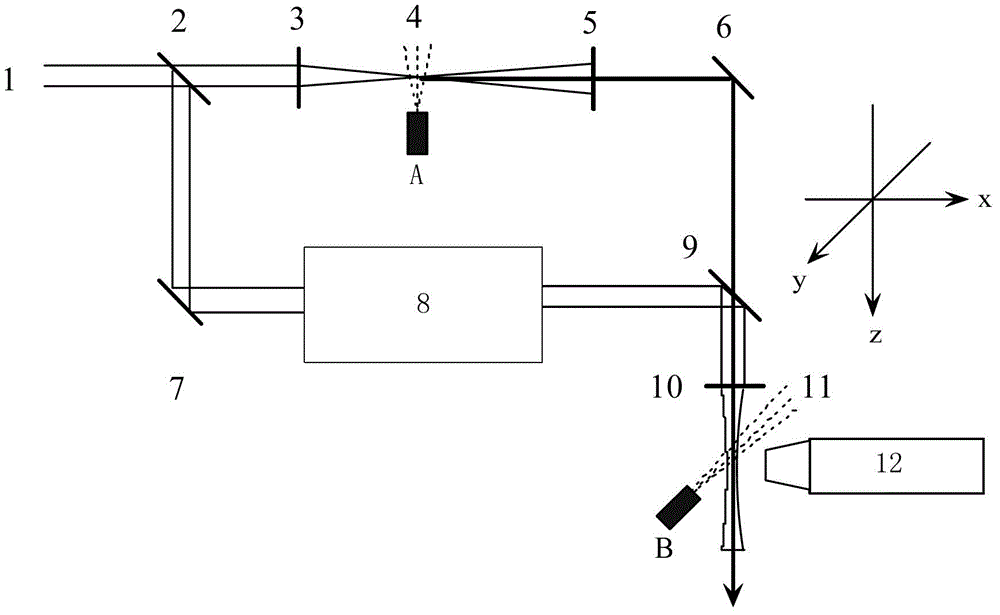

[0049] Such as figure 1 As shown, the ultra-strong femtosecond laser pulse full parameter in-situ measurement system of this embodiment includes: a picosecond or sub-picosecond laser pulse 1, a spectroscope 2, a separator 5, a laser pulse compression unit 8, a first noble gas atom 4 and the second gas atom 11, the first and second converging mirrors 3 and 10, the first to third mirrors 6, 7 and 9 and the photoelectron spectrometer 12; among them, the picosecond or sub-picosecond laser pulse 1 passes After the beam splitter 2 is split into two laser beams; one beam directly excites the first inert gas atoms 4 emitted from the first gas nozzle A after passing through the first convergent lens 3 to generate forward-emitted high-order harmonic radiation, namely X-rays; The X-rays and laser pulses pass through the separator to filter out the laser. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com