Aerodynamic disc-shaped suspending type glass insulator replacing clamp

A glass insulator and aerodynamic technology, applied in hand-held tools, manufacturing tools, overhead line/cable equipment, etc., to achieve the effects of improving power supply reliability, easy promotion and use, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

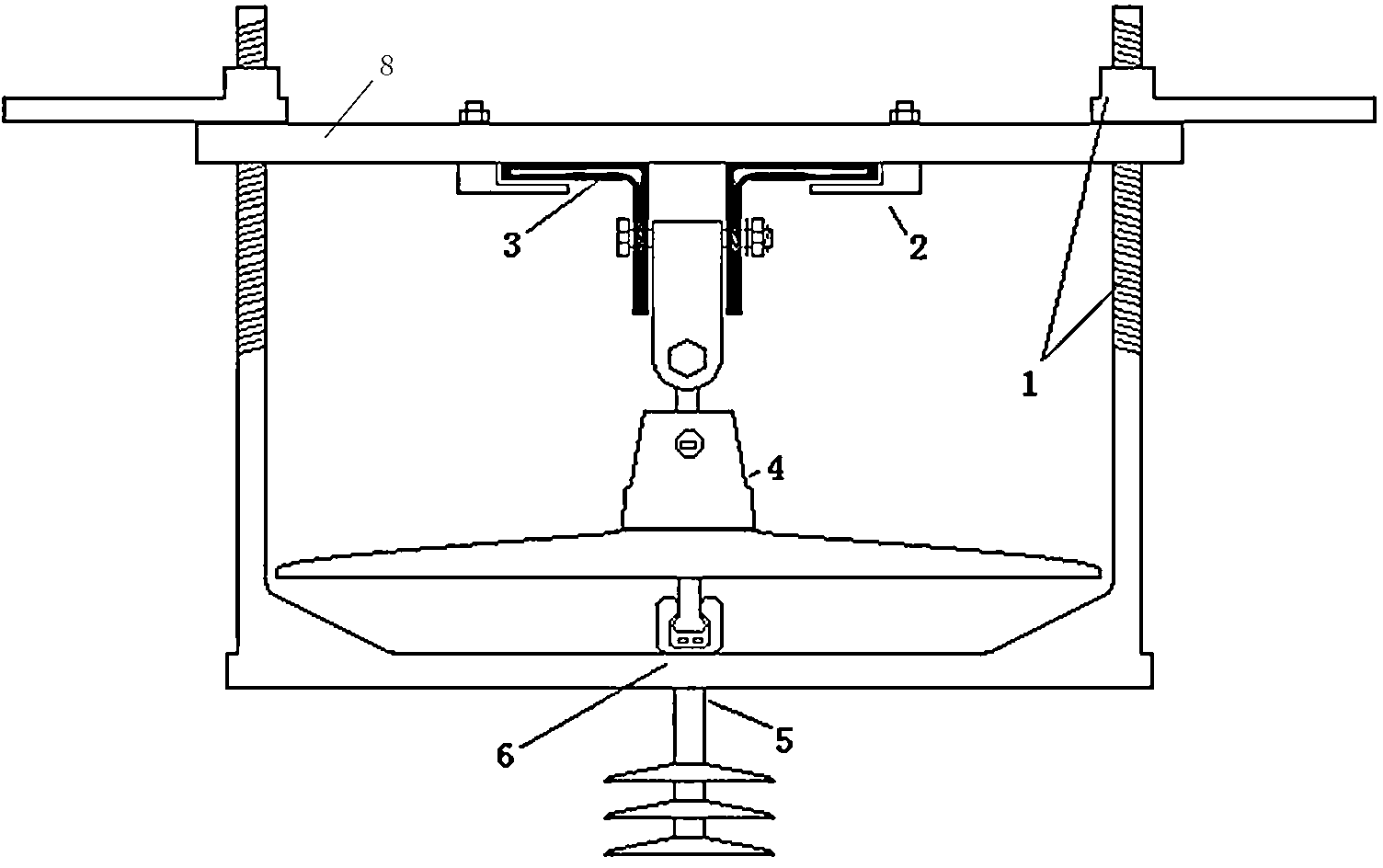

[0021] like figure 1 , 3 As shown, it is the operation of replacing and adding large edge glass insulators when the hanging point angle iron does not drink water. A screw wrench is provided on the screw 1, a fixed beam 8 is arranged between the screw 1, and a fixed pin is arranged on the fixed beam 8 2. The fixed pin 2 is fixed on the cross-arm angle iron 3 through the ingot screw. The lower part of the lead screw 1 is connected with the bowl head fixture 6 matching the insulator bowl head. The bowl head fixture 6 is fastened by the card slot and the ingot screw .

Embodiment 2

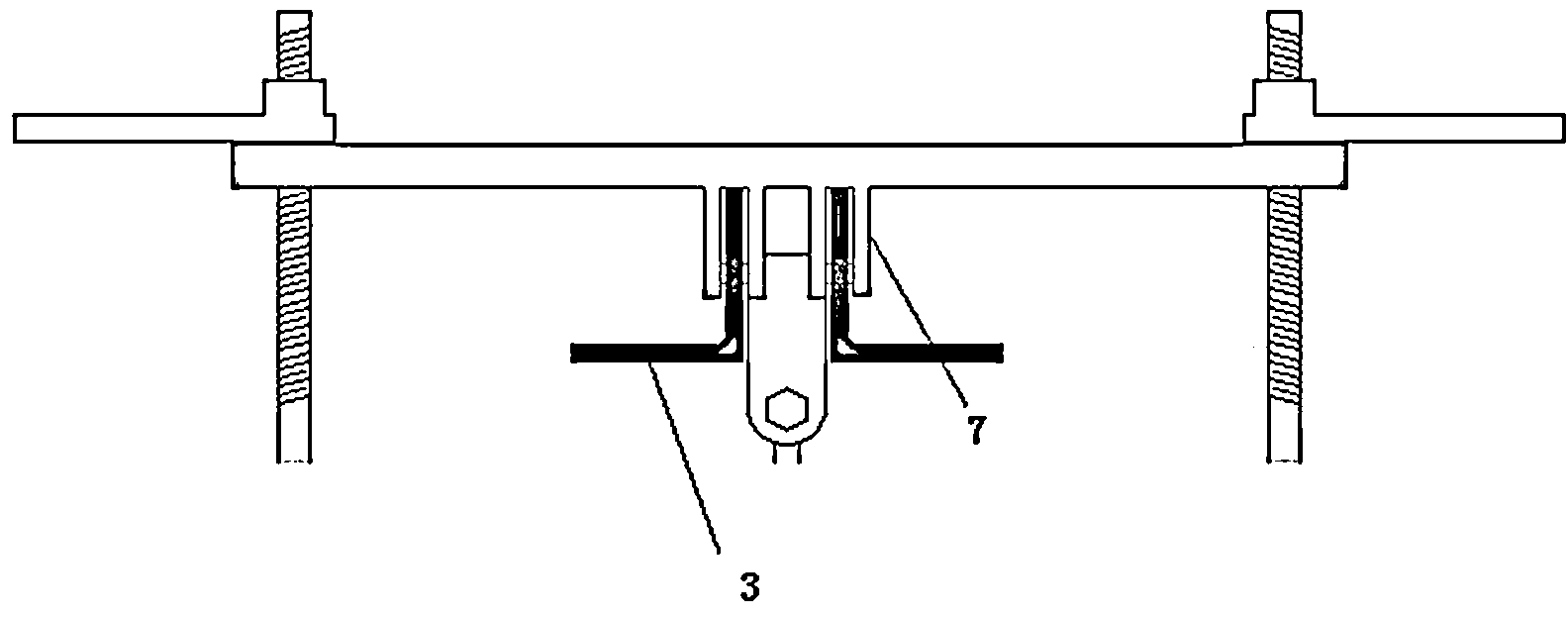

[0023] like figure 2 As shown, when drinking water for the hanging point angle iron, replace and increase the large edge glass insulator operation, the fixed beam is fixed by the protective splint 7, and the protective splint 7 is 4 V-shaped plates. Other structures are with embodiment 1.

[0024] The working process of the present invention is as follows.

[0025] The operator places the fixture fixing beam directly above the hanging point of the cross-arm. If the work is live, it needs to wear a qualified pressure equalizing suit, move the fixing pin to the cross-arm angle iron, and tighten the ingot screw. If the cross-arm angle iron is installed in place When the water is in the water, use the protective splint to fix the fixture to fix the beam, adjust the screw wrench, adjust the insulator bowl fixture to the position where it can be stuck on the insulator bowl, clamp the bowl fixture and the bowl firmly, and tighten the screws. Check the connection of each part, hang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com