Combined vibration damping device and manufacturing method of screw drilling machine test bench

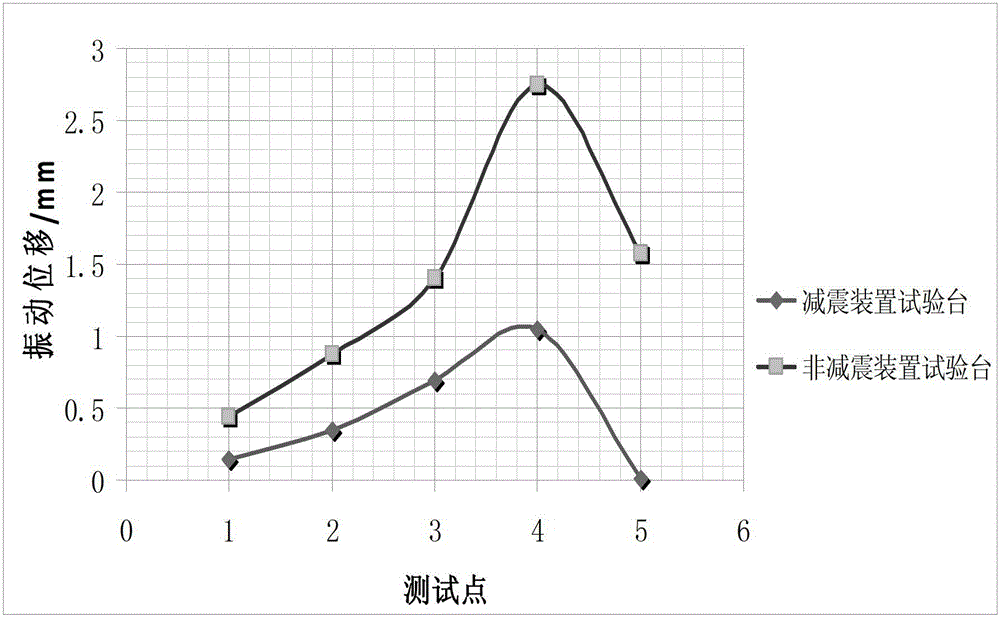

A technology of screw drilling tools and vibration damping devices, which is applied in the direction of measuring devices, testing of machine/structural components, instruments, etc., can solve problems affecting the accuracy of equipment use, and achieve the goal of improving service life, improving stability, and saving metal materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

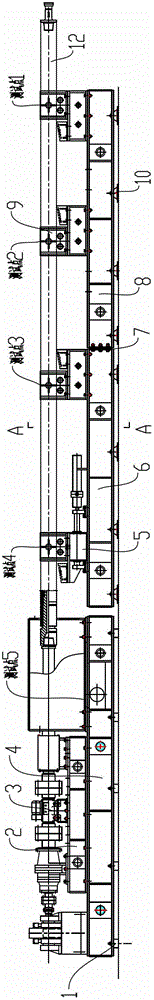

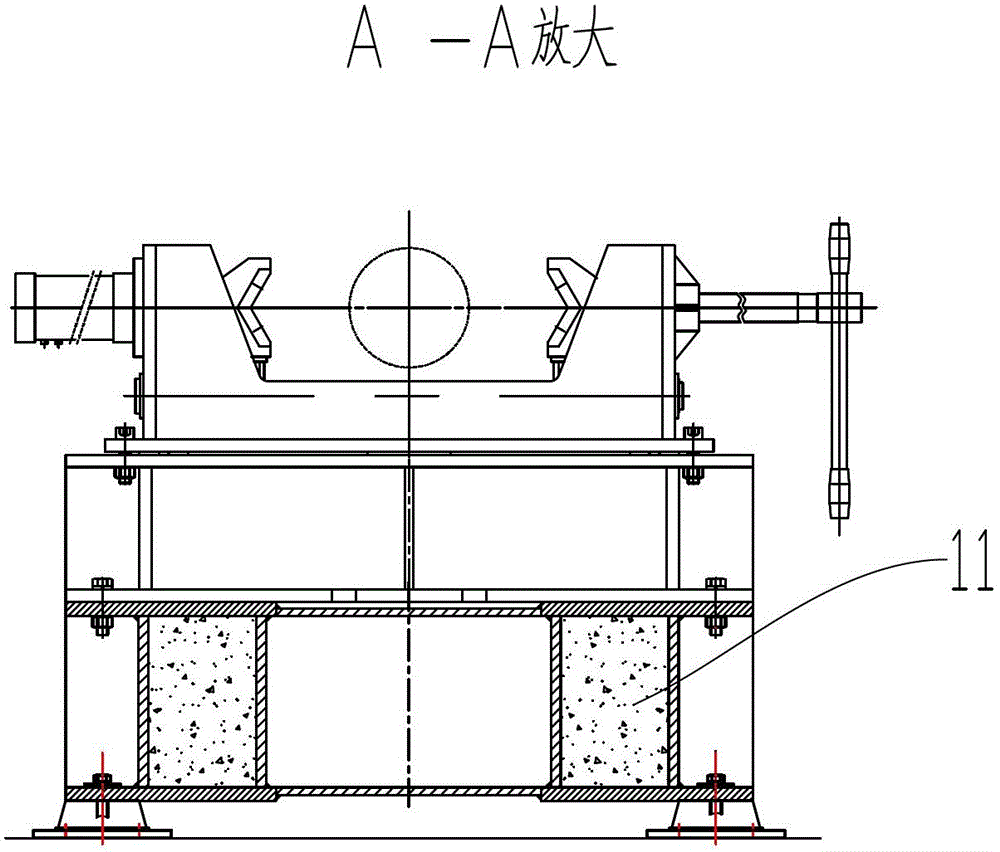

[0028] The screw drilling tool test bench is mainly used to test the screw drilling tool 12.

[0029] The basic principle of performance testing of screw drilling tools: under the premise of keeping the volume flow rate of the circulating liquid flowing into the screw drilling tool at a given value, by applying different torque loads at the power output end of the screw drilling tool, the drilling tool can be operated under different braking torques. Work stably under different working conditions, test the output torque T, output speed n, circulation flow Q1, drilling tool inlet pressure p1, outlet pressure p2 and other parameters of the drilling tool under different working conditions, and obtain the performance of the screw drilling tool after data processing Parameter tables and characteristic curves.

[0030] The screw drilling tool testing system is mainly composed of: power system, circulation system, test bench host, hydraulic system, measurement and control system and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com