spring pusher

A pusher and internal insulation technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems of poor accuracy, high proficiency, damage to insulators, etc., to achieve the effect of improving operation accuracy and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the drawings:

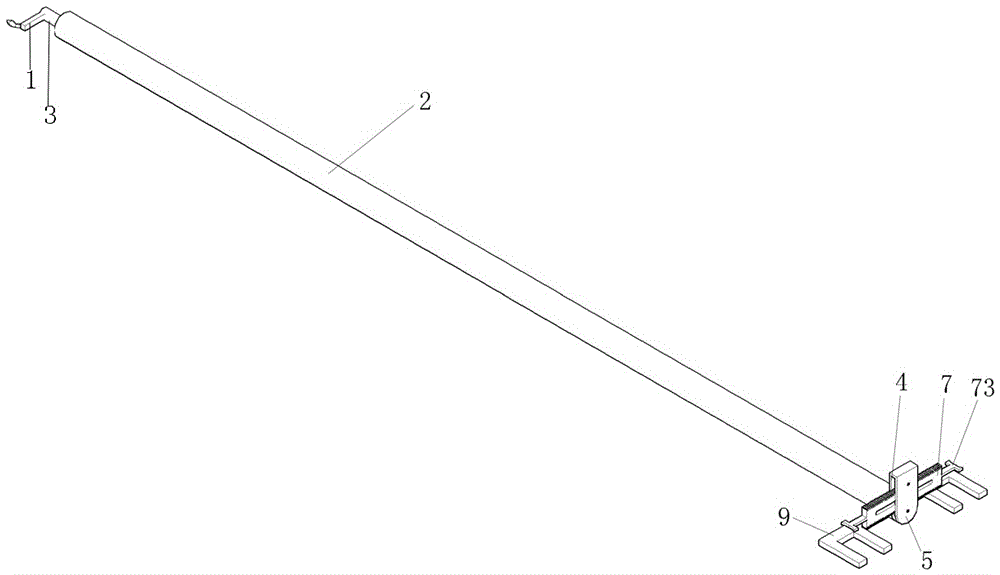

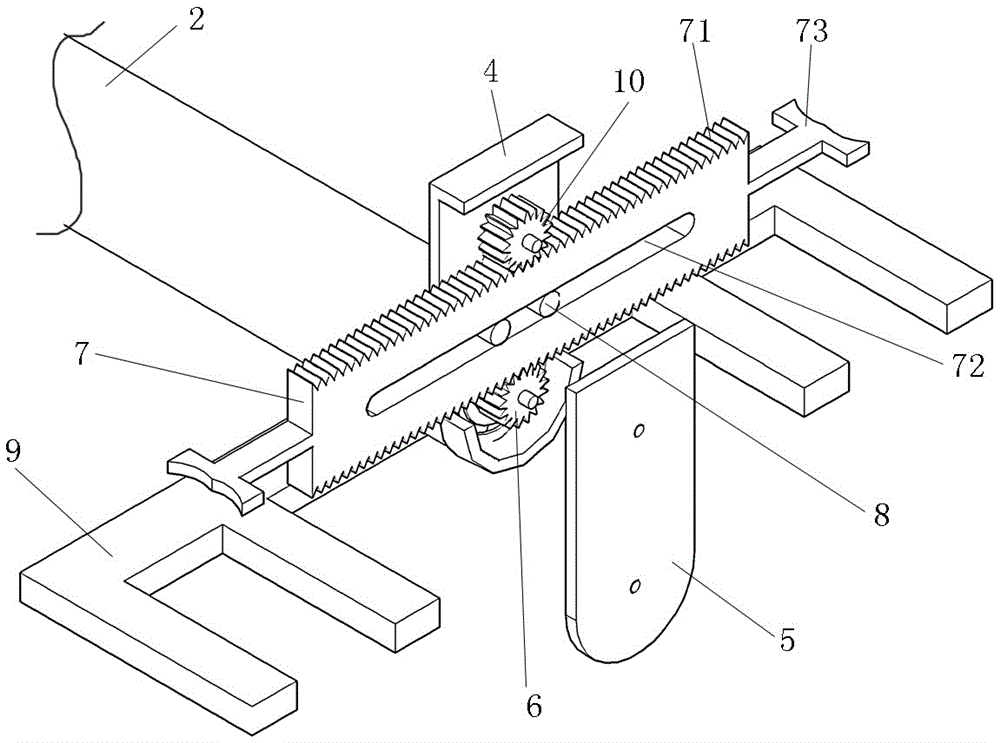

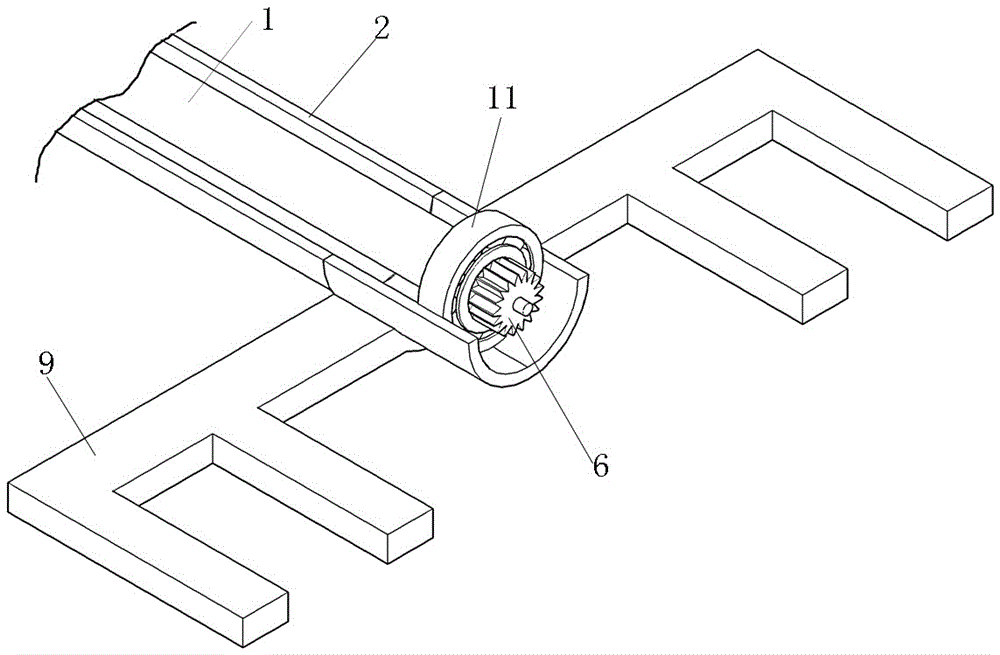

[0014] Such as Figure 1-3 As shown, the spring pusher of the present invention includes an inner insulating rod 1 and an outer insulating rod 2. The inner insulating rod 1 is sheathed in the outer insulating rod 2, and the head and tail parts of the inner insulating rod 1 are each sheathed with one to match the outer insulating rod 1. Because of the bearing 11 installed between the two layers of insulating rods, the inner insulating rods can rotate flexibly and smoothly. The lower part of the head end of the outer insulating rod 2 is fixedly connected with the bowl-head clamping slot plate 9 by screws. The bowl-head clamping slot plate 9 is composed of two symmetrical F-shaped plates. The board 4 is fixedly connected and mainly used to support all components. Two track positioning posts 8 are provided on the inner cover 4, the two ends of the gear shaft of the upper gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com