Three-dimensional (3D) camera lens and 3D camera system

A 3D and lens technology, applied in the field of 3D lens and camera system for shooting based on the above-mentioned lens, can solve problems such as difficulty in meeting shooting requirements, deterioration of image quality, misalignment of front group lens and rear group lens, etc., and achieve convenient shooting , the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

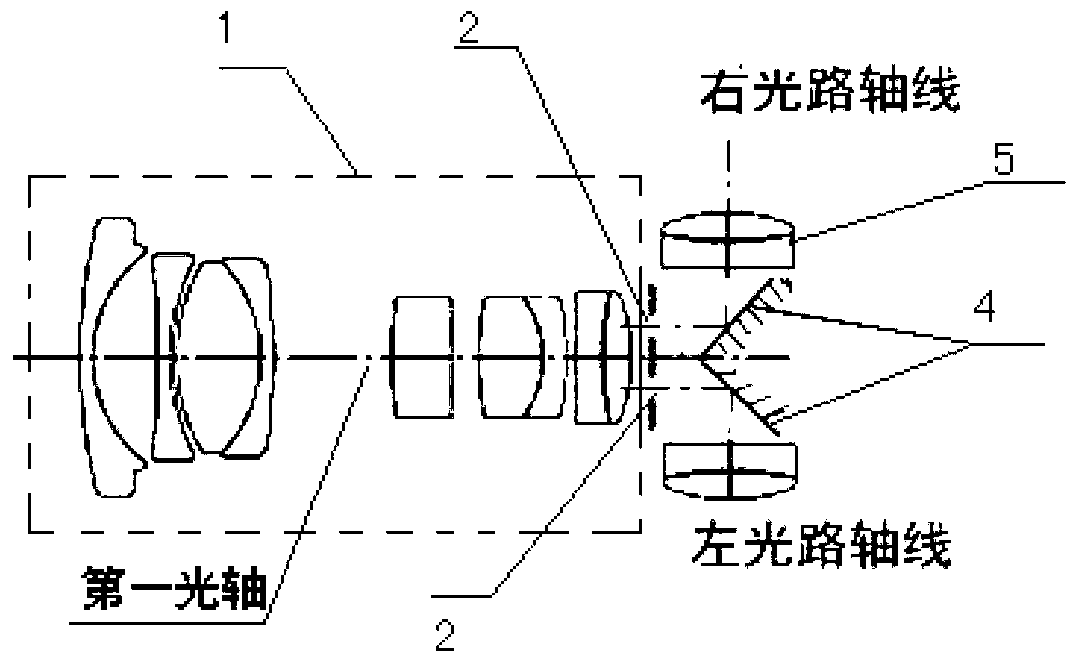

[0074] Embodiment one (see image 3 ), the two first reflectors 4 are respectively located at the rear side of a pair of apertures (the meaning of the rear side referred to in the text is that the side of the exit light path of the corresponding component corresponds to the right side of the figure at the same time), and each first reflector The mirror is at an angle of 45 degrees to the axis of one aperture, so that the light passing through one aperture can propagate outward along the direction perpendicular to the first optical axis. and, due to image 3 Among them, the sides of a pair of second reflectors close to each other are parallel, that is, symmetrically distributed in the paper, and the left optical path axis and the right optical path axis are actually on the same straight line.

Embodiment 4

[0075] Embodiment four (see Figure 5 ), a pair of apertures are distributed perpendicular to the paper surface, and like Embodiment 1, are distributed symmetrically with respect to the first optical axis, and the axes of the apertures are parallel to the first optical axis. At this time, each aperture corresponds to a first reflecting mirror. At this time, the sides where the two first reflecting mirrors 4 are close to each other are staggered, that is, they are distributed perpendicularly to the paper, and the reflected left optical path axis and right optical path The axes are parallel to each other in a plane perpendicular to the first optical axis.

Embodiment 5

[0076] Embodiment five (see Figure 6 ) is also similar to Embodiment 1, a pair of apertures are distributed perpendicular to the paper surface, in this embodiment, only a first reflector 4 is arranged on the rear side of one of the apertures, and the first reflector and one of the apertures The axis of the aperture is 45 degrees, and the rear side of the other aperture does not place the first reflector, and the light passes directly through it for imaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com