Disperse dye application

A technology of disperse dyes and textile fabrics, applied in the direction of azo dyes, organic dyes, monoazo dyes, etc., can solve the problems of poor comprehensive fastness, poor dyeing effect, low sublimation fastness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

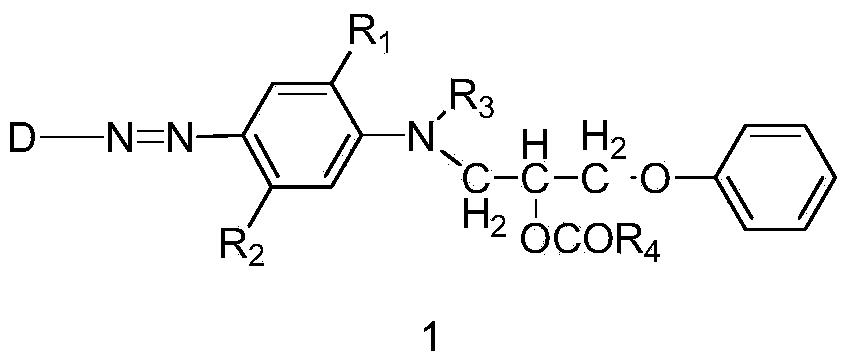

Image

Examples

Embodiment 1

[0143] The preparation of embodiment 1 compound 6

[0144]

[0145] At room temperature, add 67 parts by weight of 30% sodium hydroxide aqueous solution into a three-necked flask, then add 47 parts by weight of phenol and 5 parts by weight of PEG-400 under stirring, stir evenly, and then use dropwise Slowly add 66 parts of heavy epichlorohydrin into the funnel dropwise for about 1-2 hours. After the dropwise addition, slowly raise the temperature to 50°C-55°C for reaction. After 3h-5h, the raw materials react completely, add 50mL of water to fully dissolve the solid, and then Stand for stratification, remove the water phase, add 100mL of water for washing, and adjust the pH to neutral with a small amount of dilute hydrochloric acid, stir well and then stand for stratification, collect the oil phase, and distill under reduced pressure to remove excess epichlorohydrin and water. 52 g of the compound of the following formula was obtained, the yield was 70.5%, and the HPLC pur...

Embodiment 2

[0146] Example 2 Compound 4 (R 1 for H, R 2 for H, R 3 for the preparation of ethyl)

[0147] Add 18 parts by weight of N-ethylaniline and 30 parts by weight of acetic acid into a three-necked flask, stir evenly and then slowly raise the temperature to 50°C, then slowly add 24 parts by weight of compound 6 dropwise from a constant pressure dropping funnel for about 3 hours ~ 4h, after the addition, keep it warm at 50°C for 3h ~ 4h to complete the reaction, and compound 4 (R 1 for H, R 2 for H, R 3 Ethyl) in acetic acid solution was directly used in the next reaction. Yield 97.3%, HPLC purity 92.4%, LC-MS (ESI): [M+H] + 272.2, [M+Na] + 294.2.

[0148]

Embodiment 3

[0149] Embodiment 3 compound 2-1 (R 1 for H, R 2 for H, R 3 is ethyl, R 4 for the preparation of methyl)

[0150] 29 parts of heavy compound 4 (R 1 for H, R 2 for H, R 3 Ethyl) into a three-necked flask, slowly warm up to 50°C, at this temperature, slowly add 13 parts of heavy acetic anhydride dropwise from a constant pressure dropping funnel, dropwise for about 2 hours, and keep warm at 50°C until the reaction of the raw materials is complete , to obtain compound 2-1 (R 1 for H, R 2 for H, R 3 is ethyl, R 4 Methyl) in acetic acid solution, yield 96.1%, HPLC purity 94.3%, LC-MS (ESI): [M+H] + 314.4, [M+Na] + 336.4.

[0151]

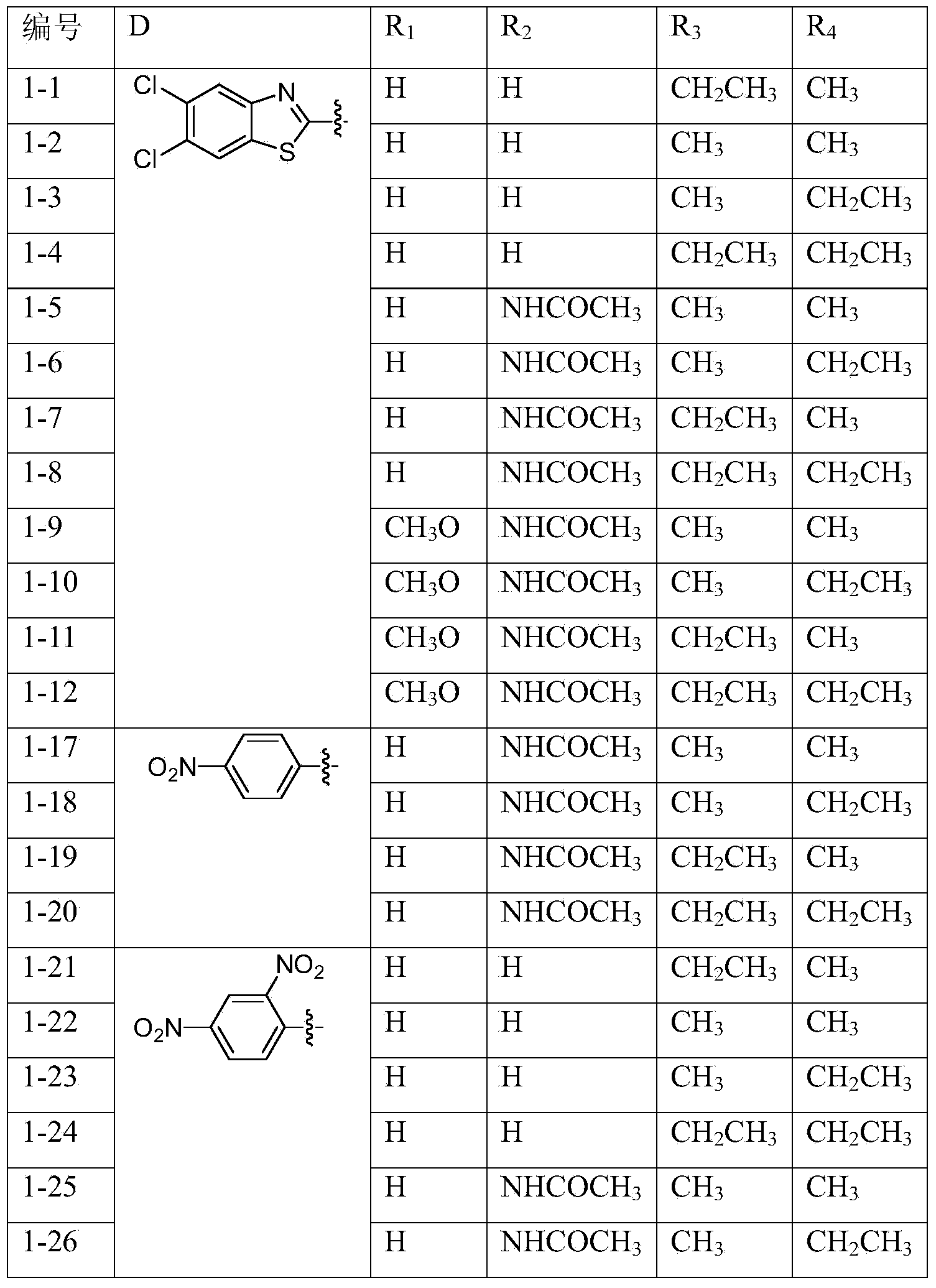

[0152] Compounds 2-1 to 2-12 were prepared according to the methods of Examples 1 to 3, and the relevant experimental data and structural identification data are shown in Table 1.

[0153] Table 1 Experimental data and structural identification data of compounds 2-1~2-12

[0154]

[0155]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com