Method for measuring and calculating influence on high-temperature performance of asphalt caused by oil content

A high-temperature performance and asphalt technology, which is applied in the field of measurement and calculation of road asphalt high-temperature performance, can solve problems such as low efficiency and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

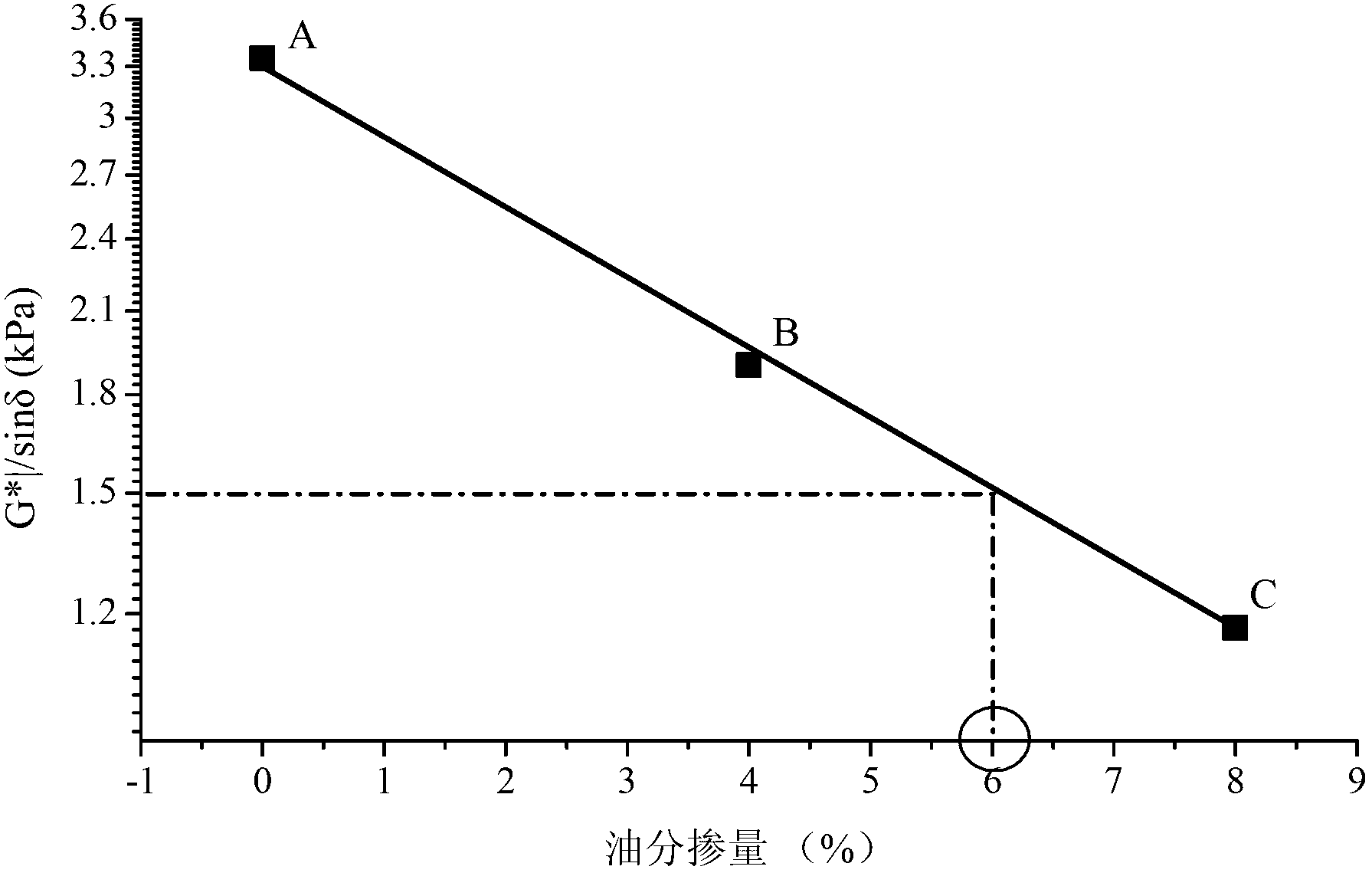

[0016] Specific embodiment one: In this embodiment, a method for measuring and calculating the high temperature performance of asphalt by oil content is carried out according to the following steps:

[0017] 1. Heat the base asphalt until it is in the form of glue and put it on a circular parallel plate with a diameter of 25mm. The distance between the plates is 1.00mm. Using a dynamic shear rheometer (DSR), according to the temperature T°C required by the product to be obtained The dynamic sinusoidal strain test is carried out under the following conditions. When the dynamic sinusoidal strain test is performed, the strain amplitude is 12%, the frequency is 1.59Hz, and the complex modulus G is obtained. A * and phase angle δ A , the index |G that characterizes the high temperature performance of asphalt is obtained by calculation A *| / sinδ A , record it as A;

[0018] 2. Heat the base asphalt to 150°C, use heat preservation equipment to keep the heated base asphalt at a con...

specific Embodiment approach 2

[0027] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the base asphalt is heated to a slurry state and placed on a circular parallel plate with a diameter of 25 mm, and the distance between the plates is 1.00 mm. Tangential rheometer (DSR), according to the temperature T °C required by the product to be tested, the dynamic sinusoidal strain test is carried out. The strain amplitude during the dynamic sinusoidal strain test is 12%, and the frequency is 1.59Hz, and the complex modulus G is obtained. A1 and a phase angle of δ A1 , the index |G that characterizes the high temperature performance of asphalt is obtained by calculation A1 | / sinδ A1 ; Repeat the above steps to get the complex modulus G A2 and phase angle δ A2 The index |G that characterizes the high temperature performance of asphalt is obtained by calculation A2 | / sinδ A2 , get|G A1 | / sinδ A1 and |G A2 | / sinδ A2 The average value of , which is recor...

specific Embodiment approach 3

[0028]Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the base asphalt is heated to 150°C as described in step 2, and the temperature of the heated base asphalt is kept constant to 150±5°C by using heat preservation equipment. Add 2% oil of the base asphalt to the base asphalt under temperature conditions, and then use high-speed stirring equipment to stir for 30 minutes at a stirring speed of 4500 rpm to obtain modified asphalt I. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Complex modulus | aaaaa | aaaaa |

| Complex modulus | aaaaa | aaaaa |

| Complex modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com