Non-batching type collecting device of warp knitting machine

A coiling and warp knitting machine technology, applied in the field of textile machinery, can solve the problems of troublesome collection of woven nets, inconvenient storage and transportation, overlapping on the stacking rollers, etc., and achieve the effect of avoiding unsmooth net collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

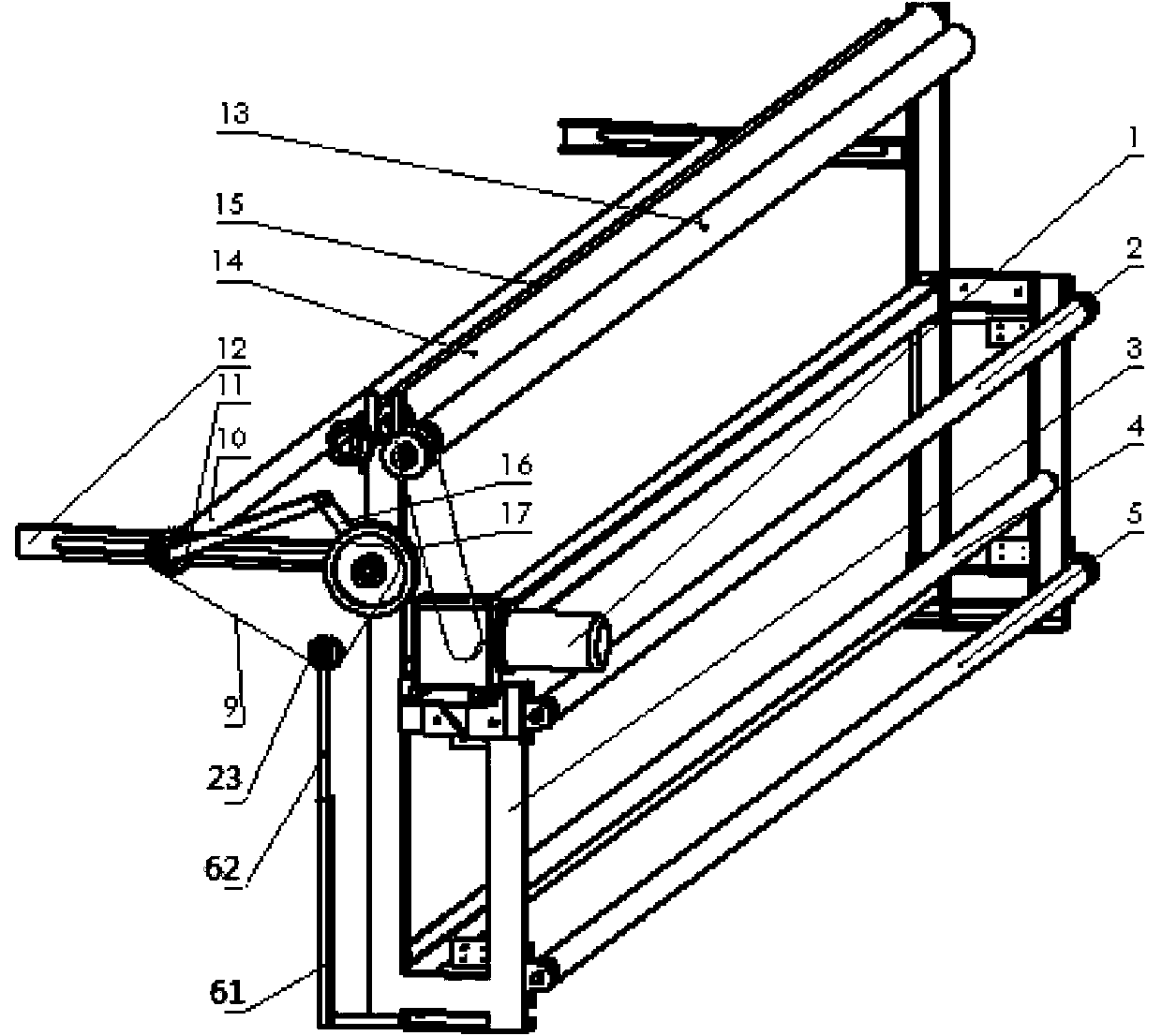

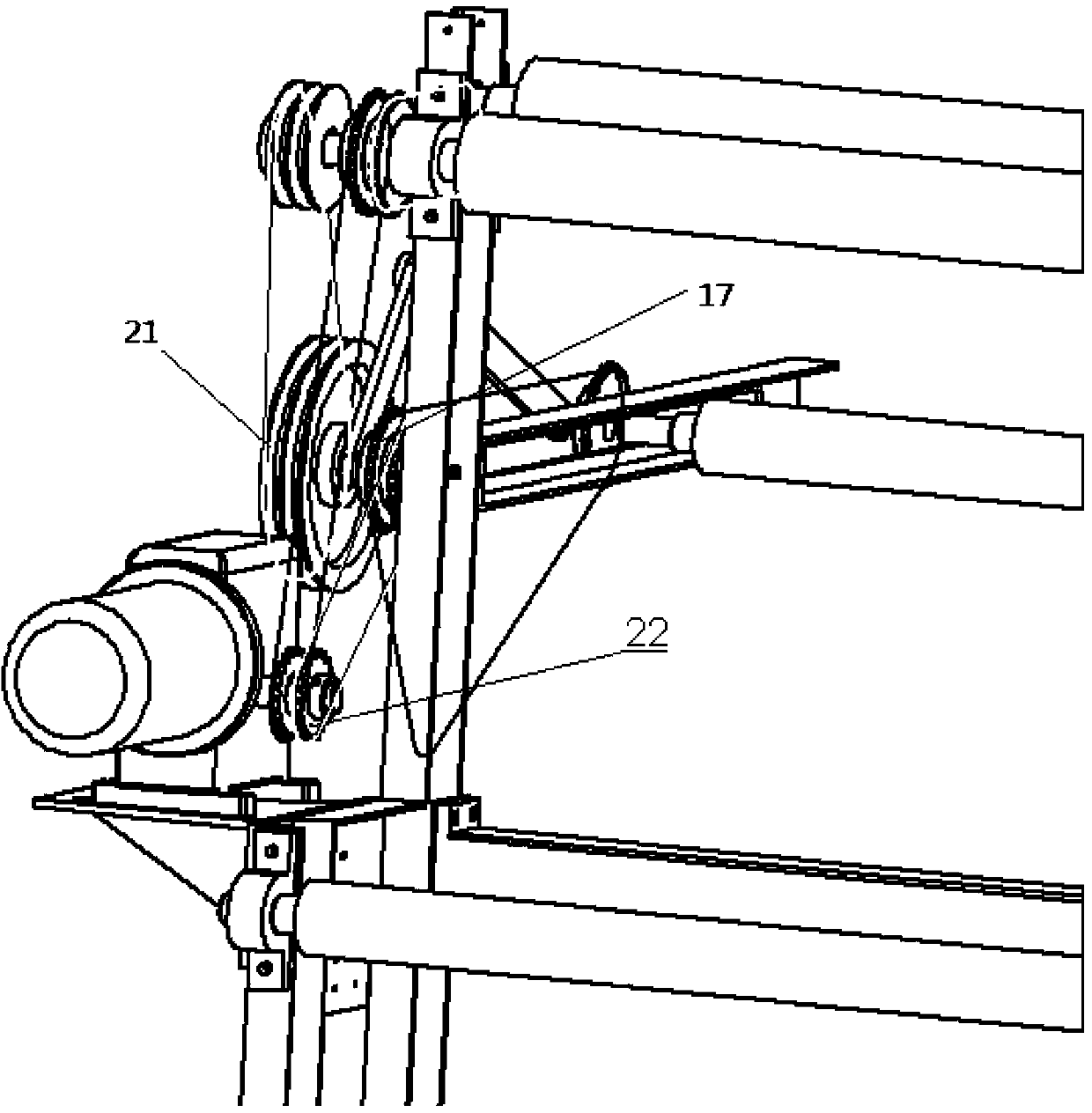

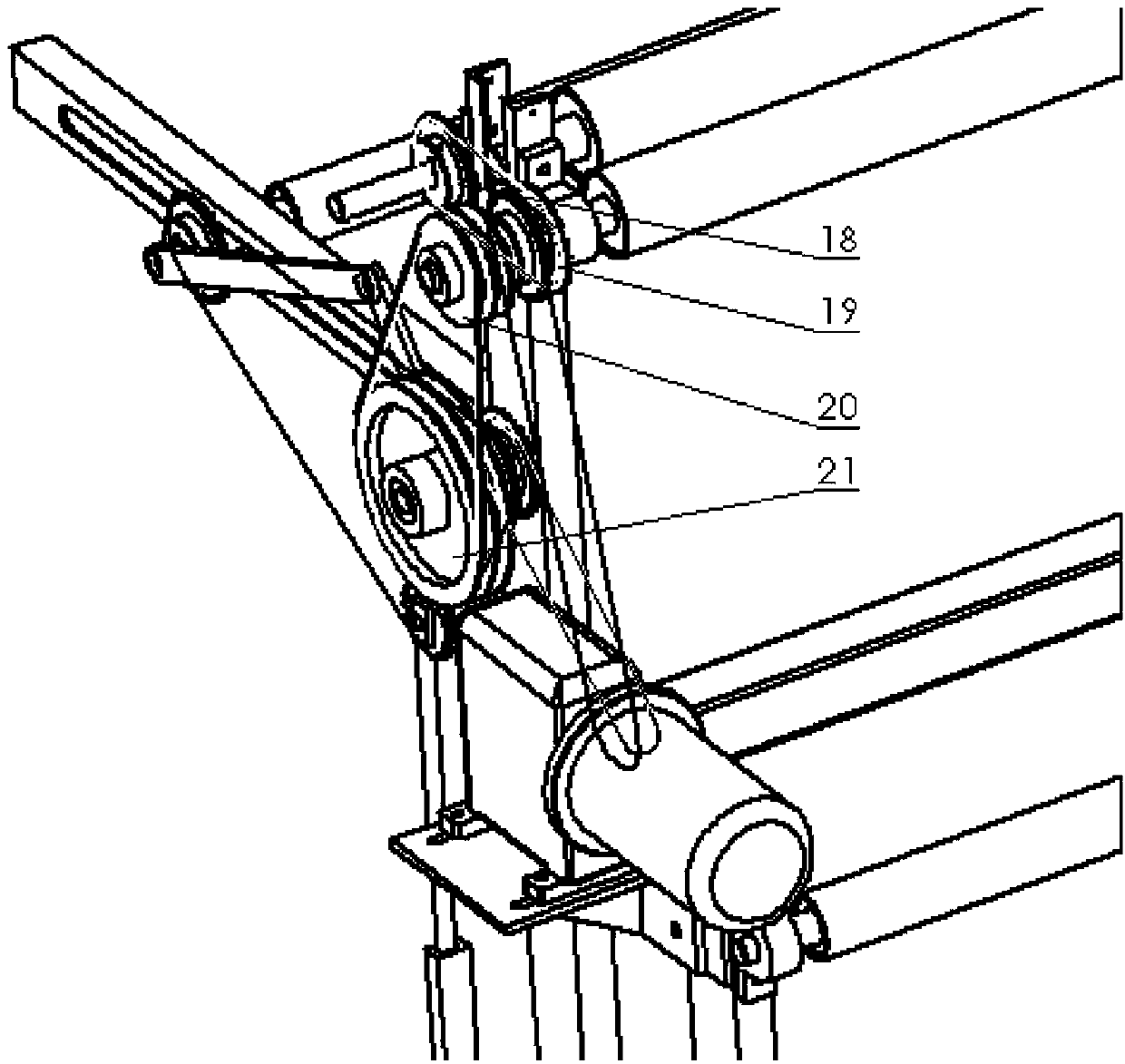

[0018] like figure 1 , 2 , 3 and 4, a kind of non-coiling type collection device of a warp knitting machine, including a frame 3 and a driving mechanism installed on the frame 3, a cloth rolling mechanism and a back and forth stacking mechanism, and the driving mechanism drives the cloth rolling mechanism And the reciprocating folding mechanism, the cloth rolling mechanism transports the fabric to the reciprocating folding mechanism, and the reciprocating folding mechanism arranges the textile neatly; the reciprocating folding mechanism includes a folding roller 10, a folding roller bracket 12, a reciprocating device 16, a folding The transmission belt and the pressing wheel 23, the stacking roller bracket 12 are fixed on the frame 3, the stacking roller bracket 12 has a guide rail, the two ends of the stacking roller 10 are axially installed on the guide rail, and the stacking roller 10 is equipped with a stacking chain round 11. The reciprocating device 16 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com